Method and system for simulating thermal runaway of lithium ion battery

A technology of lithium-ion batteries and simulation methods, applied in the field of thermal runaway simulation methods and systems of lithium-ion batteries, can solve problems such as difficult to characterize the internal temperature of lithium-ion batteries, changes in battery composition materials, complex experimental devices, etc., and reduce experimental work , saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 / Graphite lithium ion battery thermal runaway simulation

[0081] Step 1: Put LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 (NCM111) The positive electrode is charged to 4.3V (vs. Li + / Li). DSC tests were carried out at heating rates of 2.5, 3.5 and 5°C / min. The results are shown in figure 1 .

[0082] Step 2: Discharge the graphite negative electrode to 0V (vs.Li + / Li), DSC tests were carried out at heating rates of 5, 10 and 15℃ / min, and the results are shown in Figure 5 .

[0083] Step 3: The electrolyte is 1mol / L LiPF 6 The solution of EC+DEC+EMC (volume ratio 1:1:1) was tested by DSC at heating rates of 5, 10 and 20℃ / min. The results are shown in Image 6 .

[0084] Step 4: Perform integral calculation and kinetic fitting on the DSC curves of the three materials at different heating rates to obtain the reaction heat and kinetic parameters of the thermal reaction of the materials.

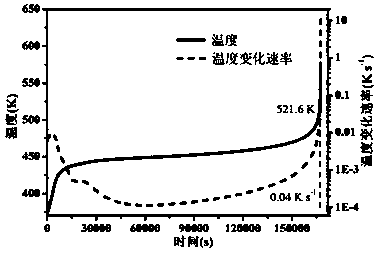

[0085] Step 5: Use COMSOL Multiphysics software to build LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2...

Embodiment 2

[0089] LiNi 0.5 Co 0.2 Mn 0.3 O 2 / Graphite lithium ion battery thermal runaway simulation

[0090] Step 1: Put LiNi 0.5 Co 0.2 Mn 0.3 O 2 (NCM523) Positive charge to 4.3V (vs. Li + / Li). DSC tests were carried out at heating rates of 2.5, 5 and 10℃ / min, and the results are shown in figure 2 .

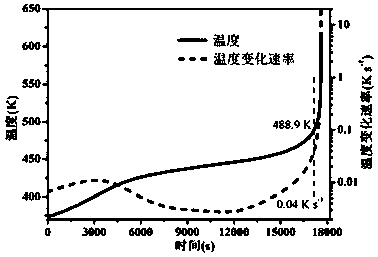

[0091] Steps 2 to 7 are the same as in Example 1. The negative electrode material and electrolyte used in NCM523 / graphite battery are the same as those in Example 1. The battery temperature and temperature change rate of NCM523 / graphite lithium ion battery thermal runaway simulation output change with time See the curve Figure 8 , The battery temperature change rate and the material reaction rate change curve with the battery temperature, see Picture 12 .

Embodiment 3

[0093] LiNi 0.6 Co 0.2 Mn 0.2 O 2 / Graphite lithium ion battery thermal runaway simulation

[0094] Step 1: Put LiNi 0.6 Co 0.2 Mn 0.2 O 2 (NCM622) Positive charge to 4.3V (vs. Li + / Li). DSC tests were carried out at heating rates of 2.5, 5 and 10℃ / min, and the results are shown in image 3 .

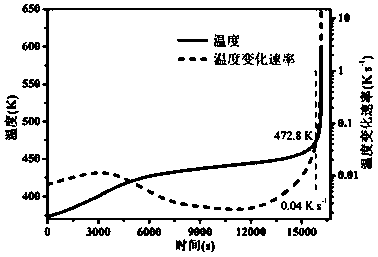

[0095] Steps 2 to 7 are the same as in Example 1. The negative electrode material and electrolyte used in NCM622 / graphite battery are the same as in Example 1. The battery temperature and temperature change rate of NCM622 / graphite lithium ion battery thermal runaway simulation output change with time See the curve Picture 9 , The battery temperature change rate and the material reaction rate change curve with the battery temperature, see Figure 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com