Double-layer copper pipe winding for track transformer

A technology for transformers and high-voltage windings, applied in the directions of transformer/inductor coil/winding/connection, transformer/inductor cooling, transformer/inductor components, etc. Problems such as low efficiency, to achieve the effect of increased voltage, extended service life, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further description will be made below in conjunction with drawings and embodiments.

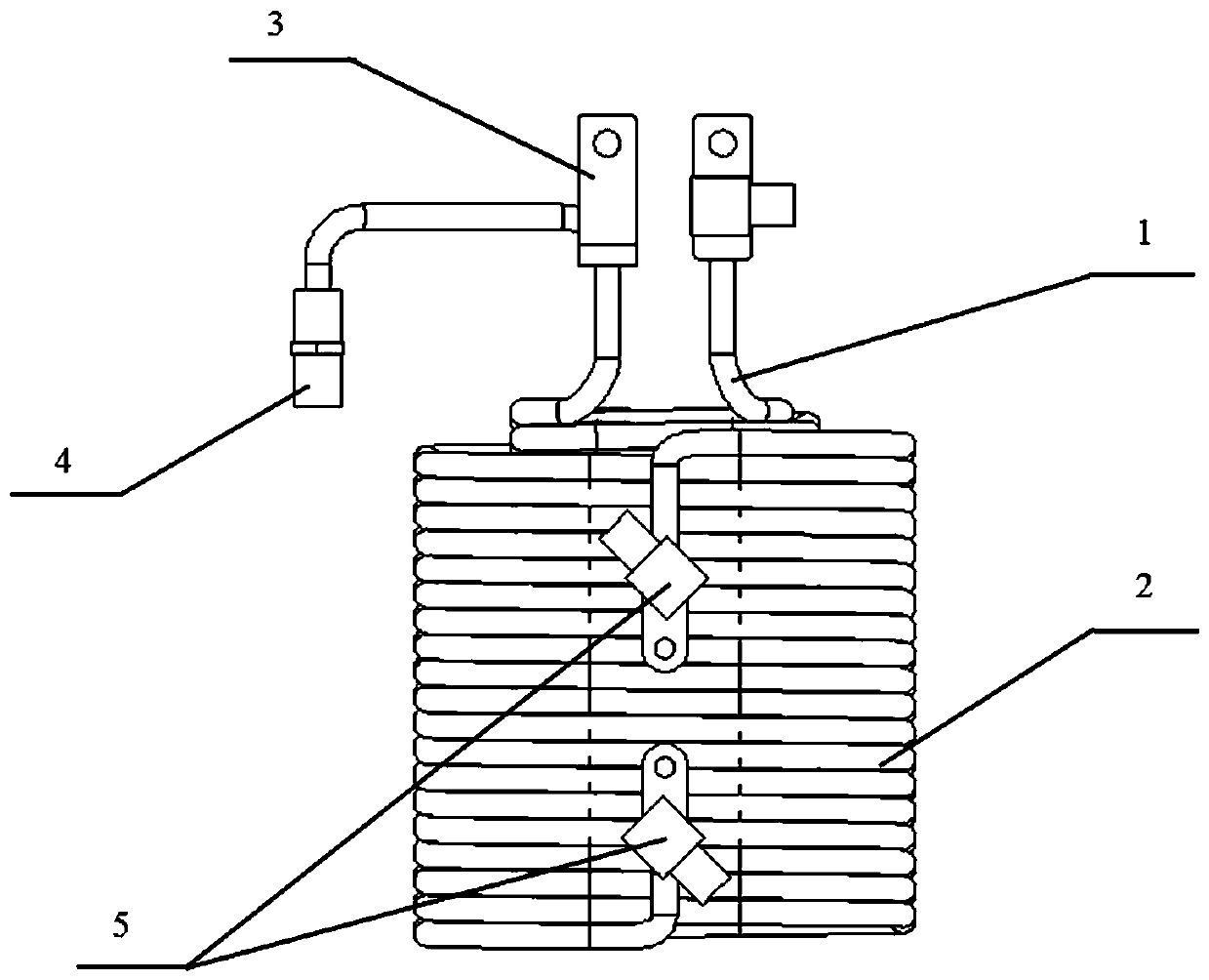

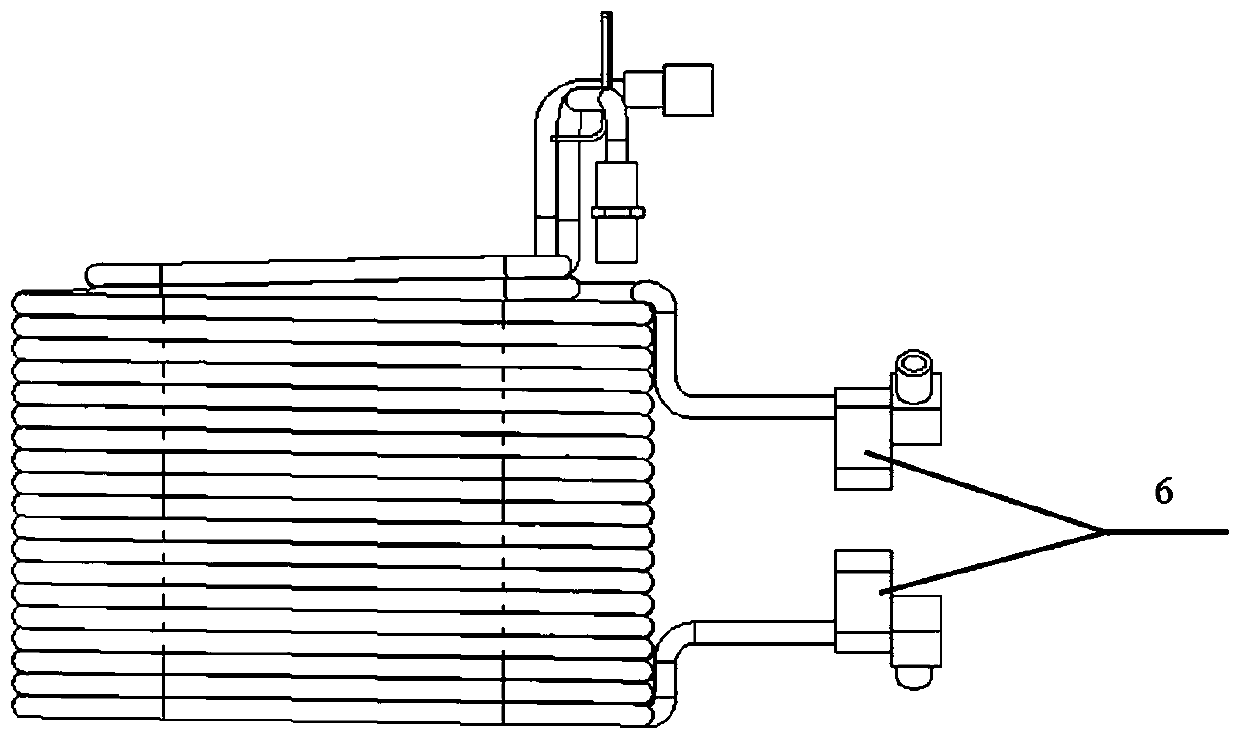

[0013] figure 1 , 2 Shown: A double-layer copper tube winding for a track transformer includes a high-voltage winding 1, a low-voltage winding 2, a high-voltage terminal block 3, a high-voltage winding straight-through ferrule joint 4, a low-voltage sleeve straight-through ferrule joint 5, and a low-voltage terminal block 6 . The high-voltage winding 1 and the low-voltage winding 2 are both wound into a rectangular structure by hollow copper tubes, and the corners of the rectangular structure transition smoothly. The high-voltage winding 1 is arranged in the low-voltage winding 2, and the outer surface of the hollow copper tube is wrapped with more than one layer of H-level insulating material. Layer, between the high-voltage winding and low-voltage winding is poured with H-grade insulating glue; the two terminals of the hollow copper tubes of the high-voltage winding and the low-vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com