Hot end seat, thermoelectric power generation system, liquid reactor, operation method of liquid reactor, and application of thermoelectric power generation system

A technology of thermoelectric power generation and thermoelectric power generation sheets, which is applied in the direction of generators/motors, electrical components, indirect heat exchangers, etc., which can solve the problem that the heat of heat pipes cannot be effectively used, reduce the efficiency of thermoelectric power generation, and cannot ensure effective heat dissipation at the condensing end of heat pipes, etc. problems, to avoid local hot spots, improve efficiency, and improve heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Hot End Block

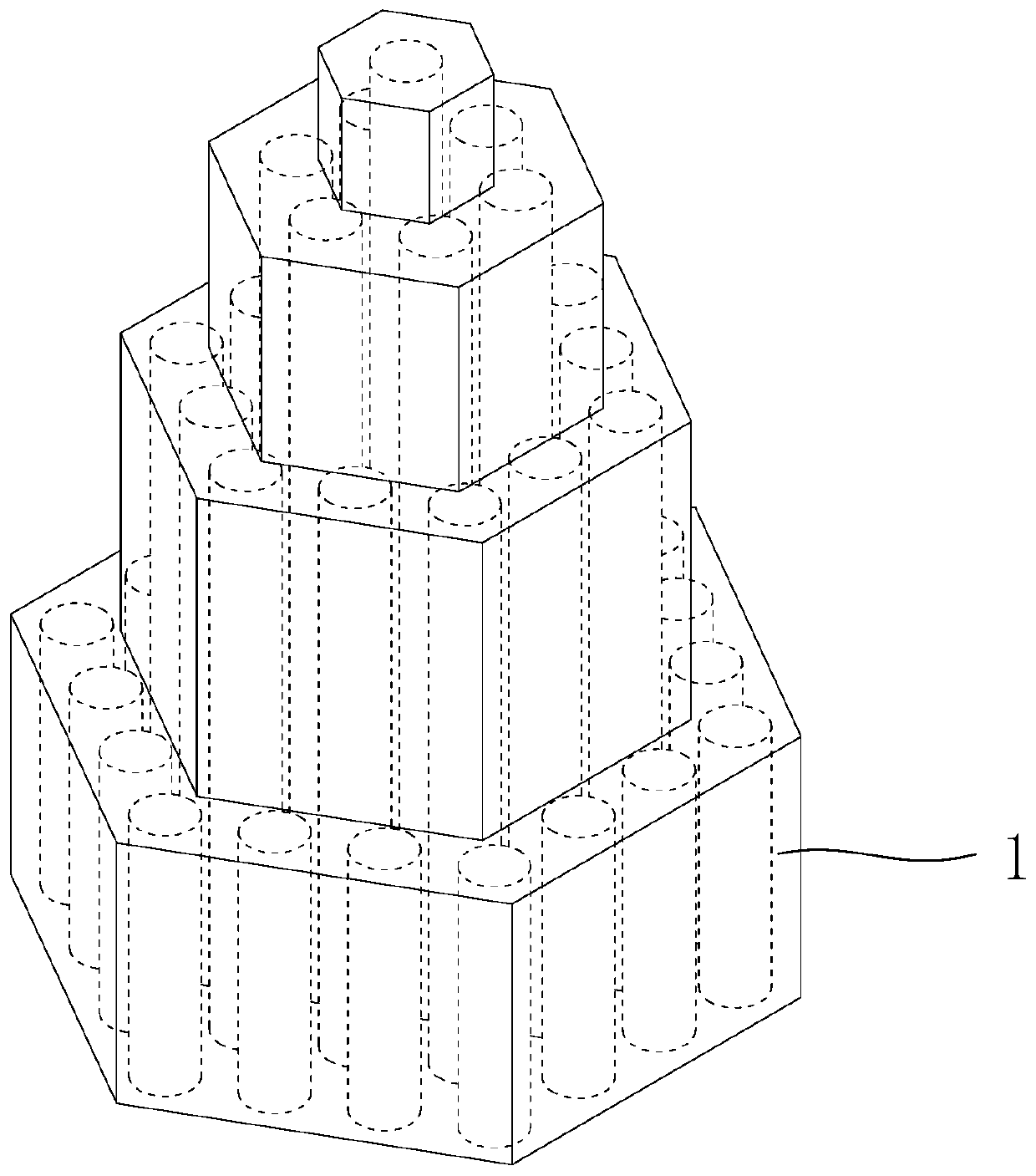

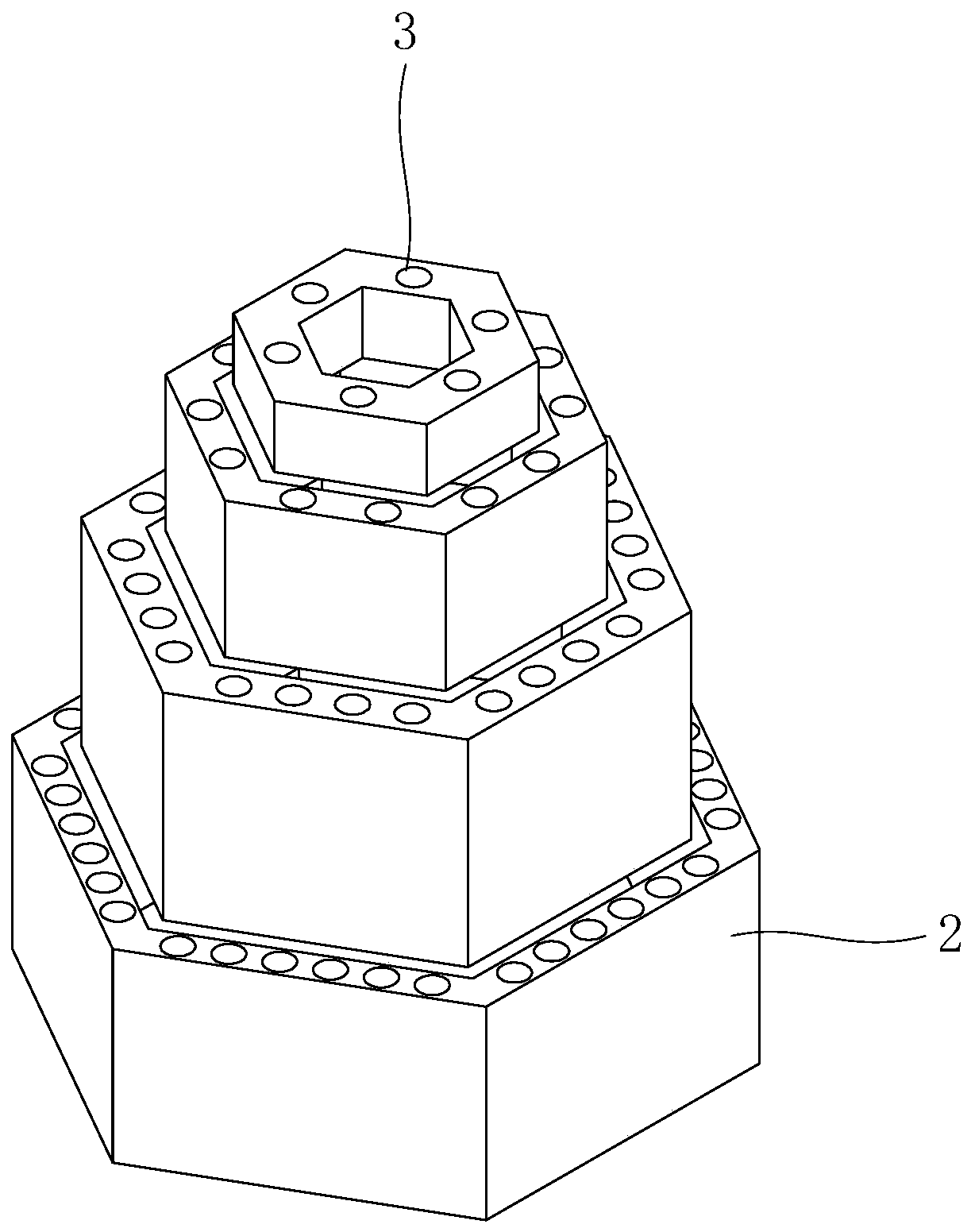

[0070] like figure 1 The hot end block shown is used to cooperate with the condensing end of the core heat pipe in the liquid stack;

[0071] The position of the top of the condensing end of the core heat pipe rises sequentially from outside to inside; and according to the height of the top of the condensing end of the core heat pipe, the condensing end of the core heat pipe is divided into the first to the first N areas;

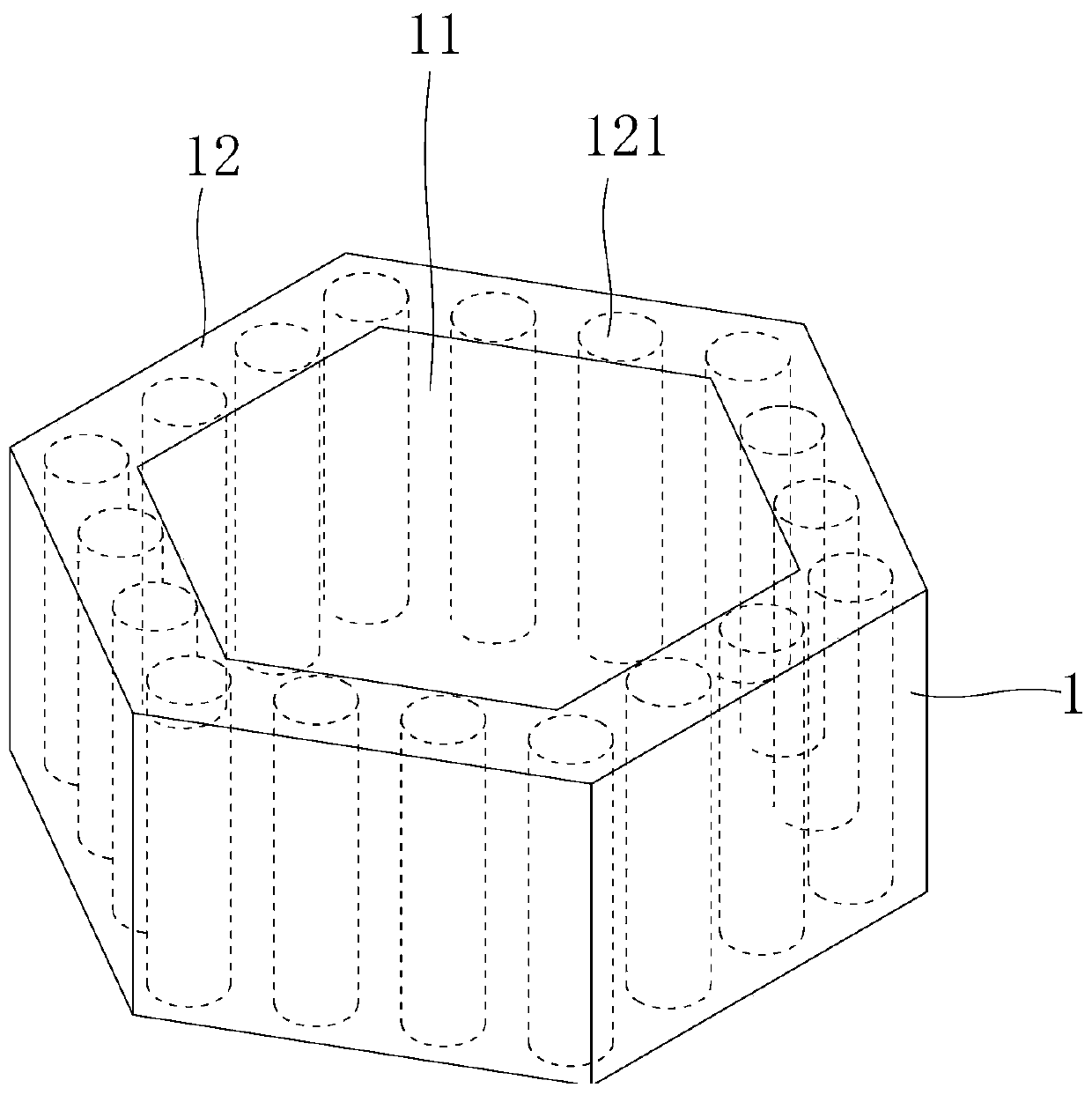

[0072] The hot end seat includes the first layer to the Nth layer of hot end sleeves from bottom to top, and the outer diameter of the hot end sleeve 1 becomes smaller from bottom to top. The structure of the first layer of hot end sleeves is shown in figure 2 ;

[0073] The hot end cover 1 of the hot end seat corresponds to the area of the condensing end of the core heat pipe;

[0074] The hot end sleeve 1 has a central body 11 and an outer peripheral body 12 surrounding the central body 11; the central body 11 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com