Organic matter adsorption and transfer device based on industrial waste gas treatment

A technology of industrial waste gas and transfer device, which is applied in gas treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. Adsorption effect, the effect of avoiding adsorption saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

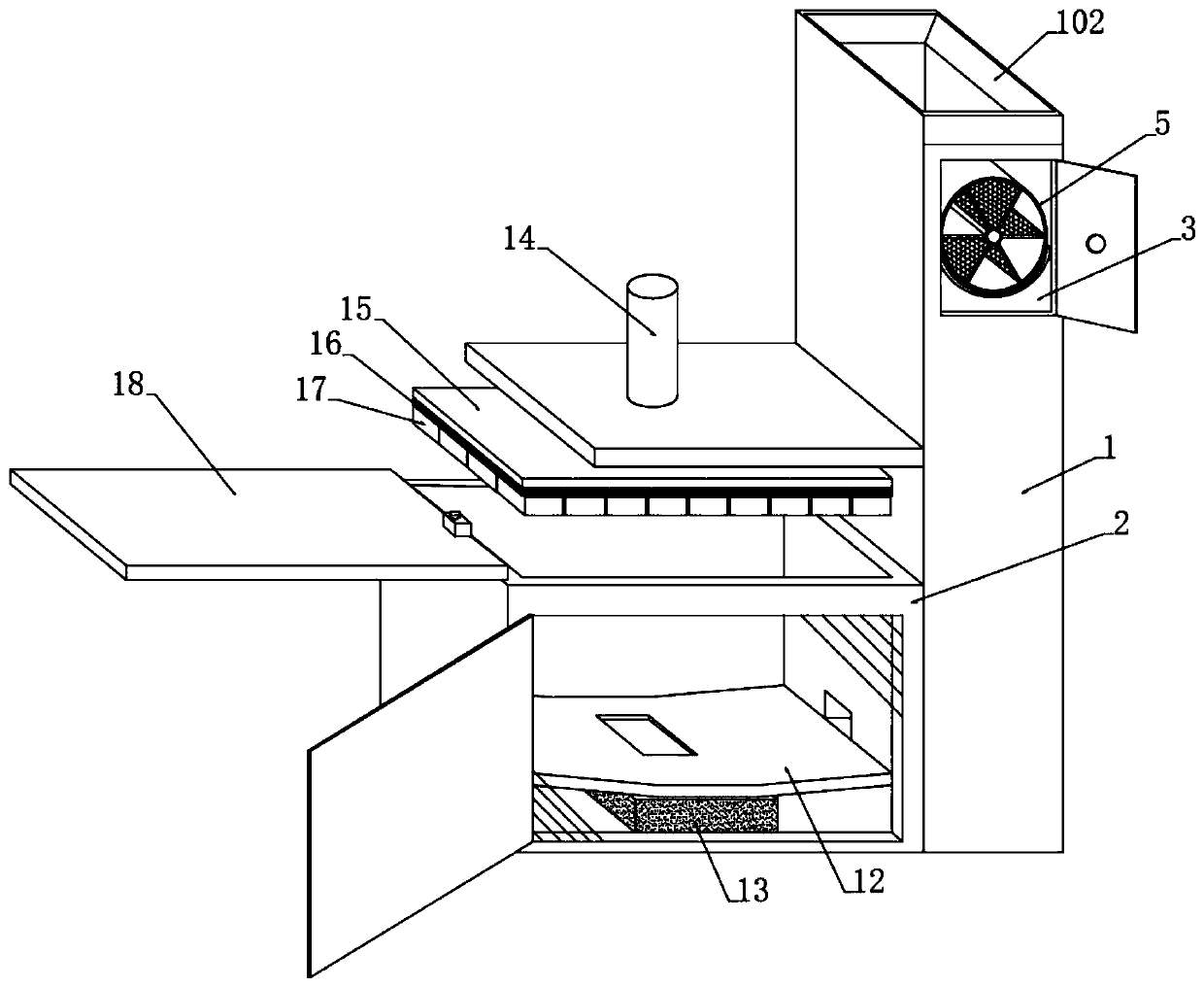

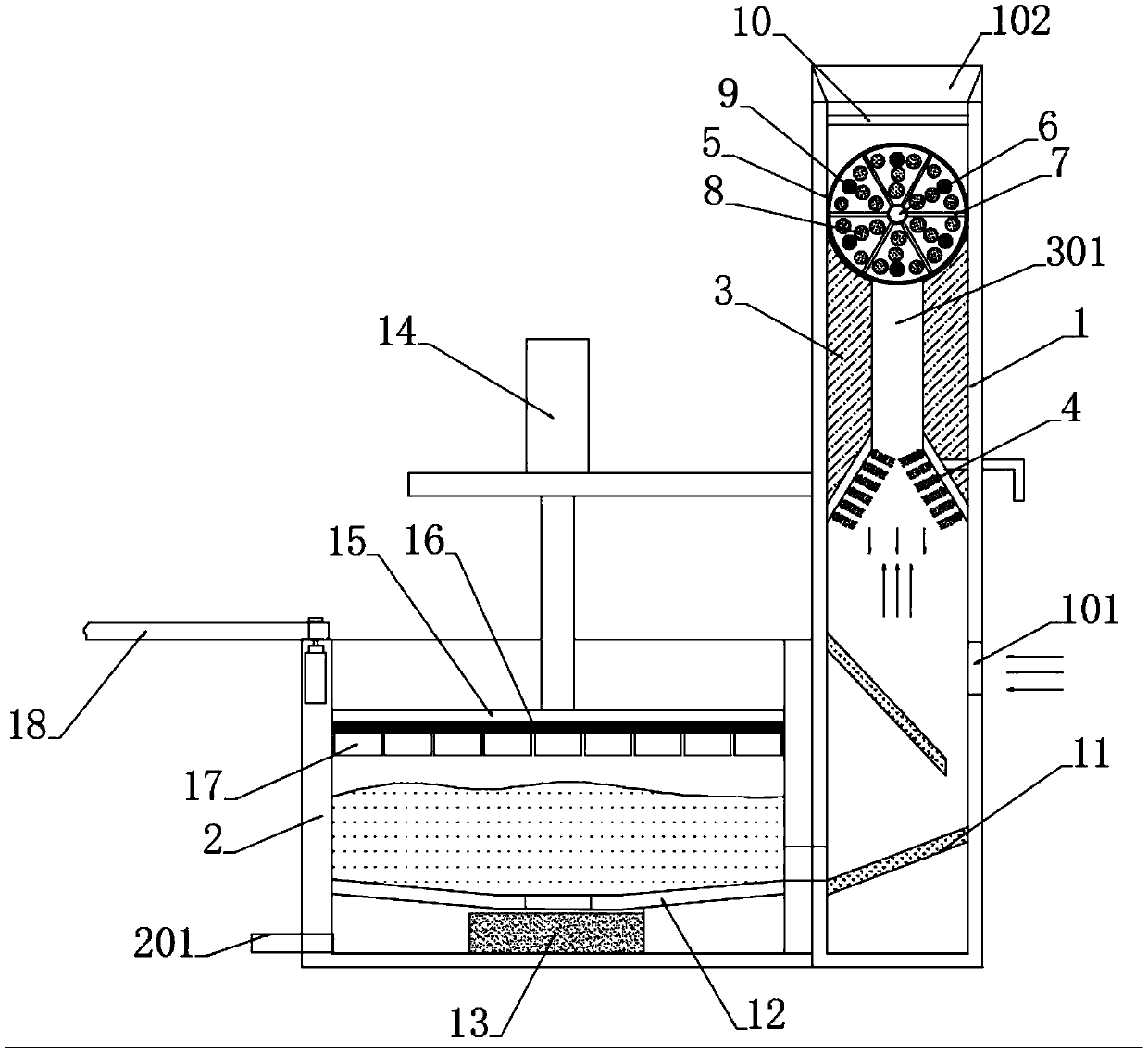

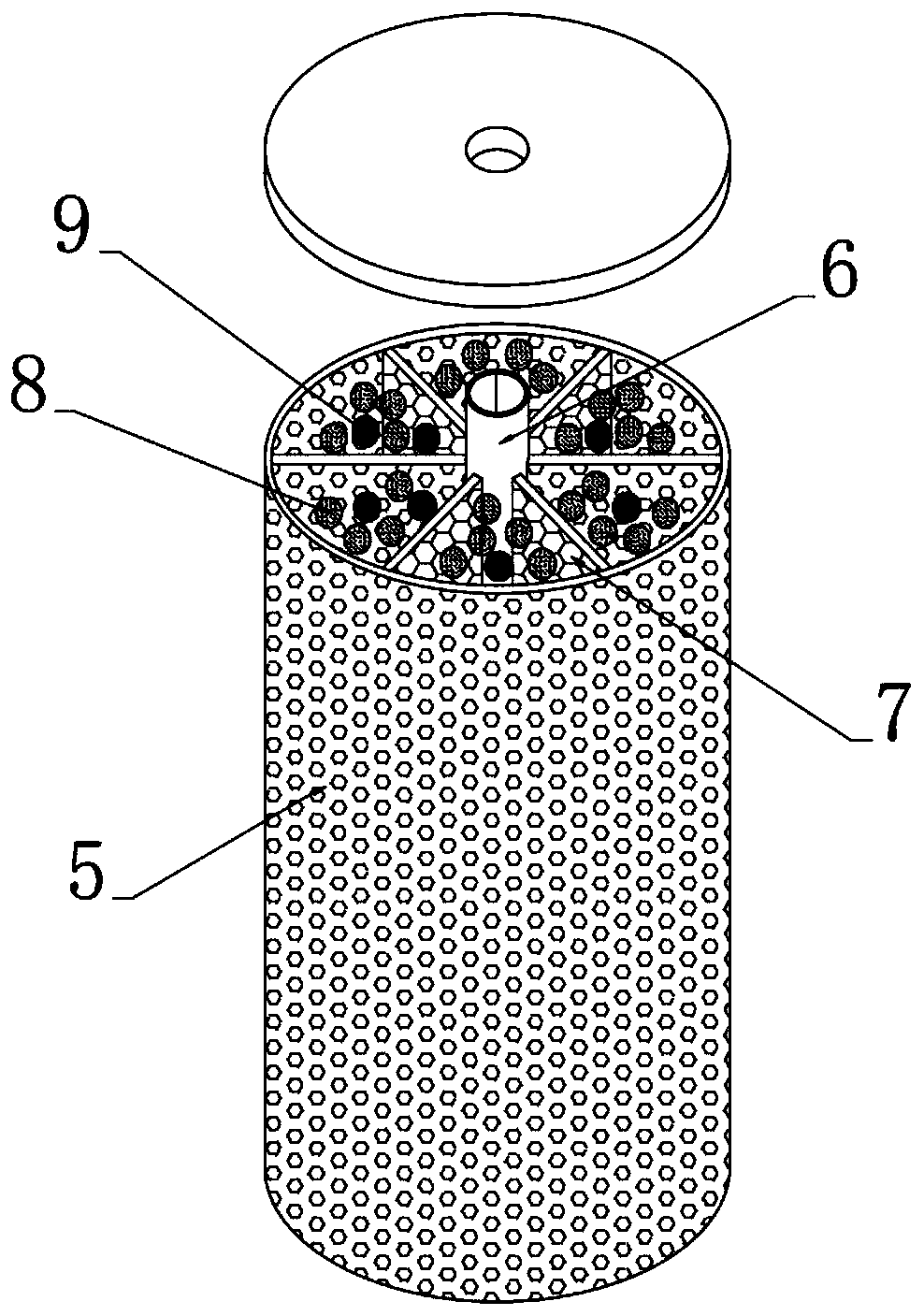

[0038] see Figure 1-3 , an organic matter adsorption and transfer device based on industrial waste gas treatment, comprising a first adsorption box 1 and a second adsorption box 2, the side of the first adsorption box 1 near the bottom end is provided with an air inlet 101, and the top of the first adsorption box 1 is An exhaust port 102 is provided, a drainage port is provided at the connection between the first adsorption box 1 and the second adsorption box 2 near the bottom, and a drain pipe 201 is installed on the outer wall of the second adsorption box 2 away from the first adsorption box 1 , the upper end of the first adsorption box 1 is fixedly connected with a diversion box 3, the inner wall of the bottom end of the diversion box 3 is fixedly installed with multiple groups of spray nozzles 4, and the top of the diversion box 3 is rotatably installed with a rotary adsorption cylinder 5 , the rotary adsorption cylinder 5 is filled with a plurality of exhaust gas adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com