Through-flow-type garbage guiding, collecting and smashing device

A crushing device and through-flow technology, applied in the field of through-flow garbage guiding and crushing devices, can solve the problems of reduced recycling quality, reduced recycling efficiency of building materials, and inability to sort and recycle plastics, wood and concrete blocks, etc., to achieve Improve the crushing effect and improve the recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

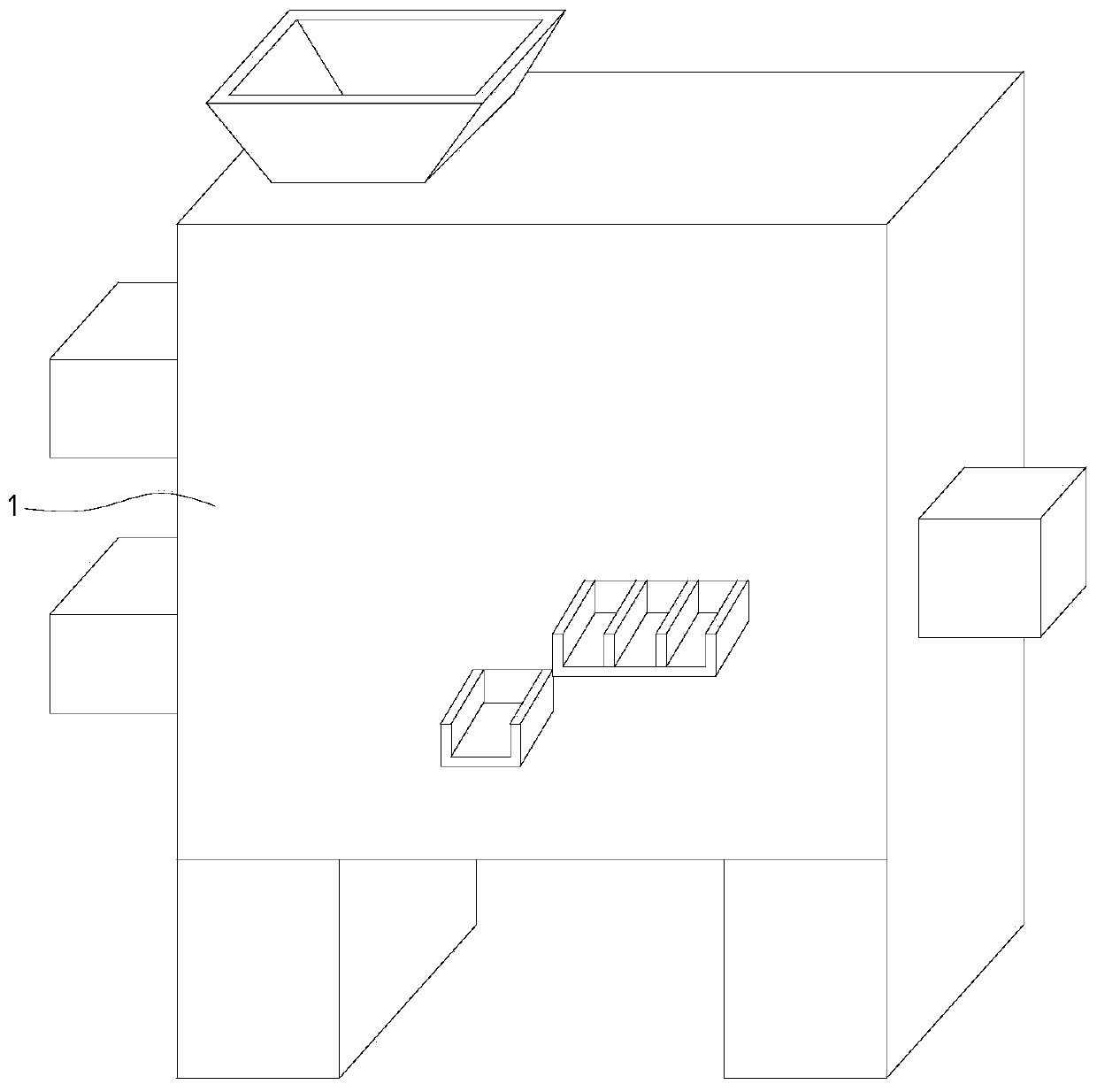

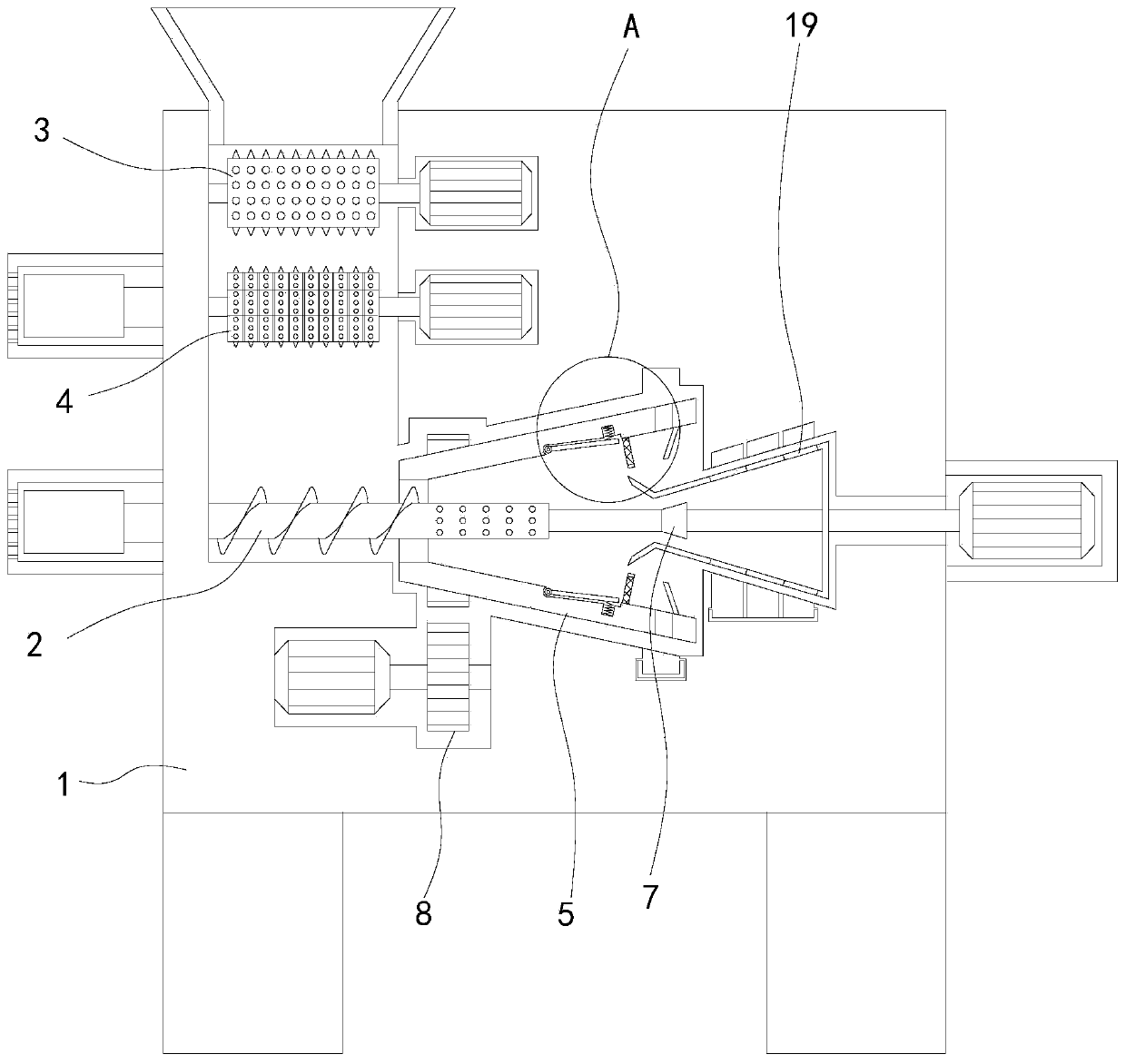

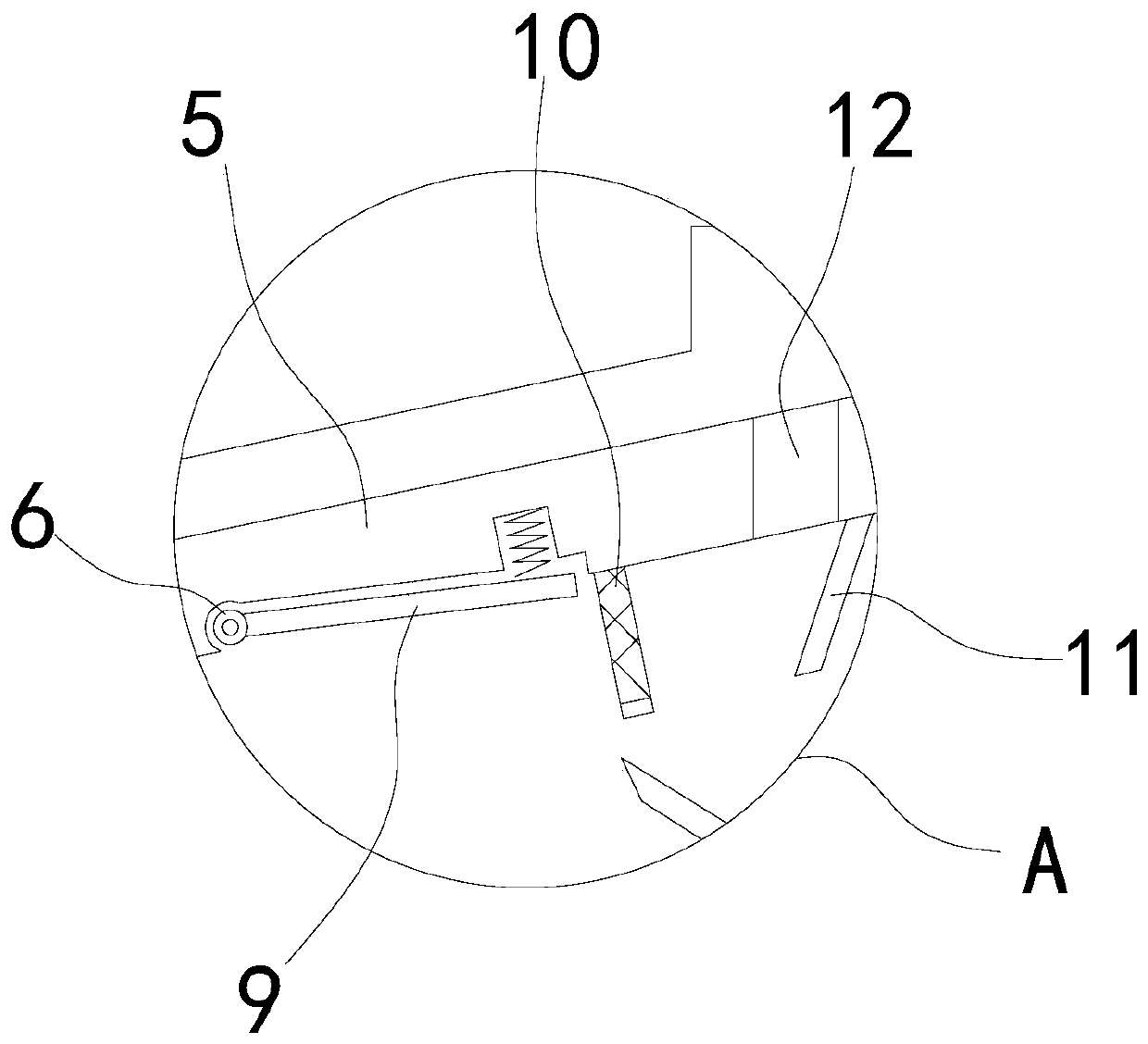

[0027] see Figures 1 to 7 , a schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a through-flow garbage guiding and crushing device.

[0028] A through-flow garbage guiding and crushing device, comprising a device main body 1, a squeeze runner 4 is fixedly installed on the left side inside the device main body 1, a material throwing sleeve 5 is fixedly installed on the inner middle end of the device main body 1, and the inner lower end of the device main body 1 Rotating rod 2 is fixedly installed, and screening cover 19 is fixedly installed on the outside of rotating rod 2 right ends.

[0029] In the specific implementation, the crushing roller 3 is fixedly installed on the upper left side of the device main body 1, the extrusion block 15 is installed movable on the outside of the extrusion runner 4, the crushing teeth are fixedly installed on the outside of the extrusion block 15, and the extrusion runner 4 is fixed inside. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com