B-part lifting balance adjusting mechanism for bottle making machine and method thereof

A technology of lifting balance and adjusting mechanism, which is applied to the special transmission machinery of glass blowing machine, glass blowing, and manufacturing tools, etc., can solve the problems of low quality accuracy of bottle bottom, reduced production efficiency, and offset of the center of gravity. , to ensure the processing accuracy and product quality of the bottom of the bottle, reduce the frequency of failures, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

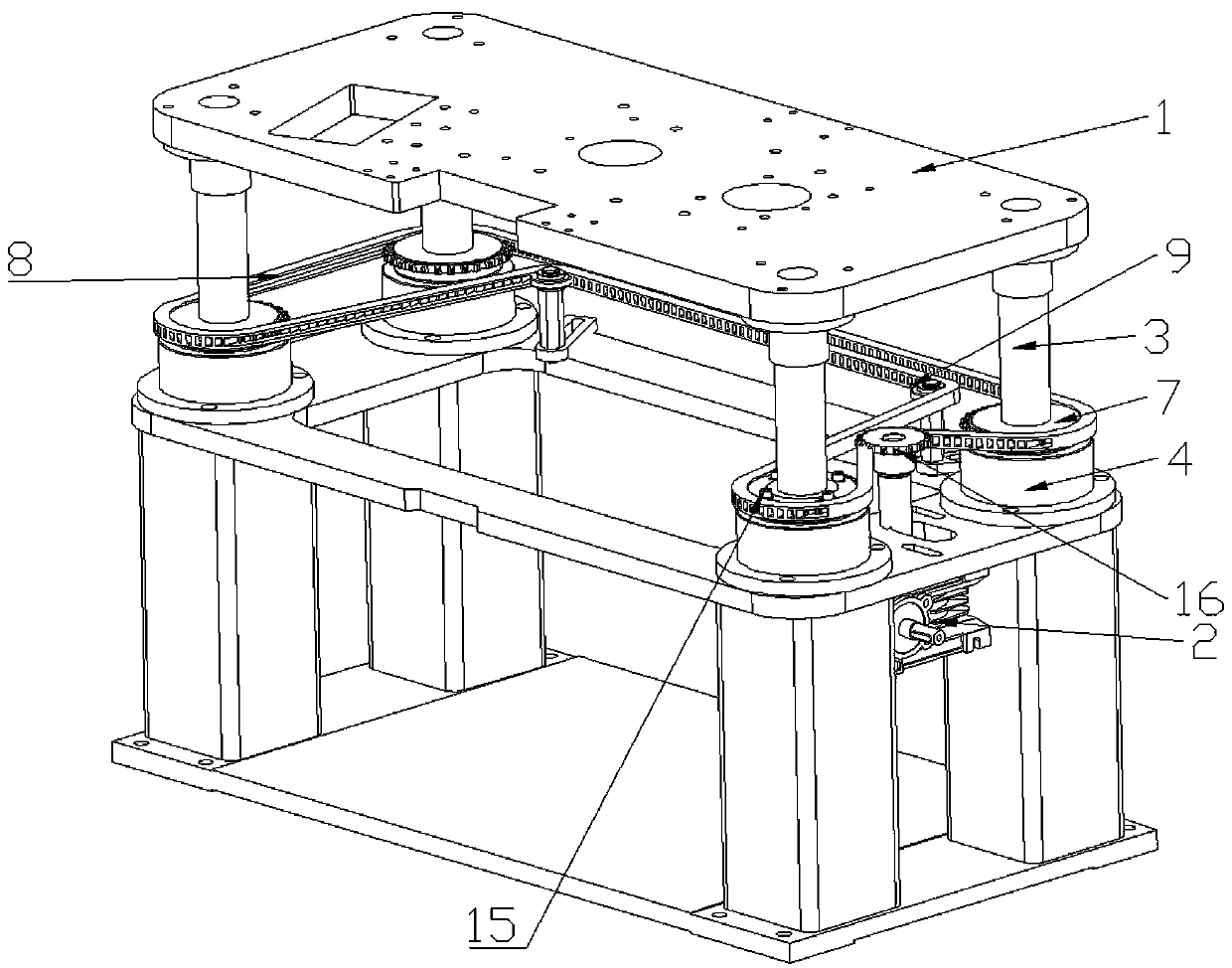

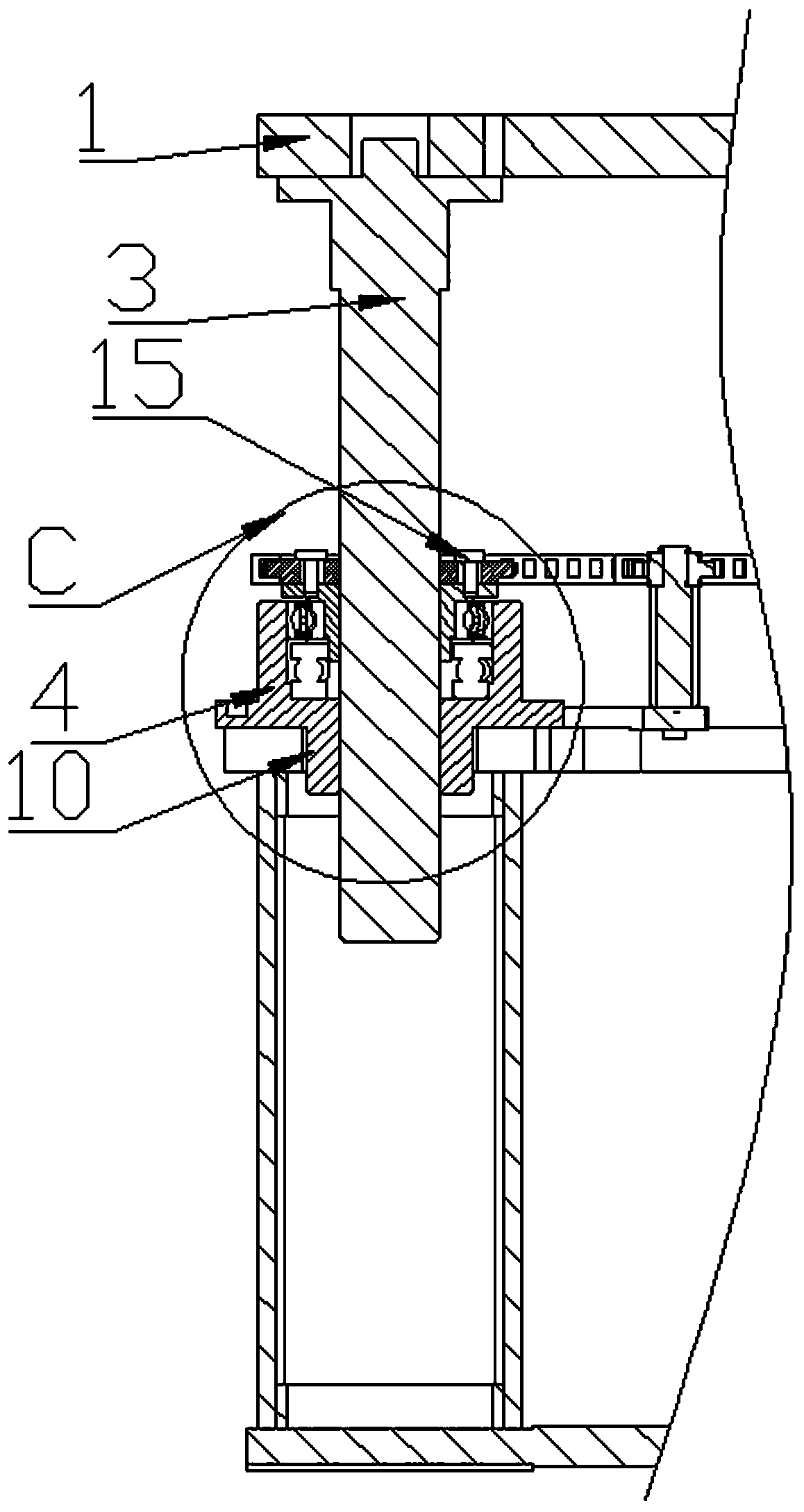

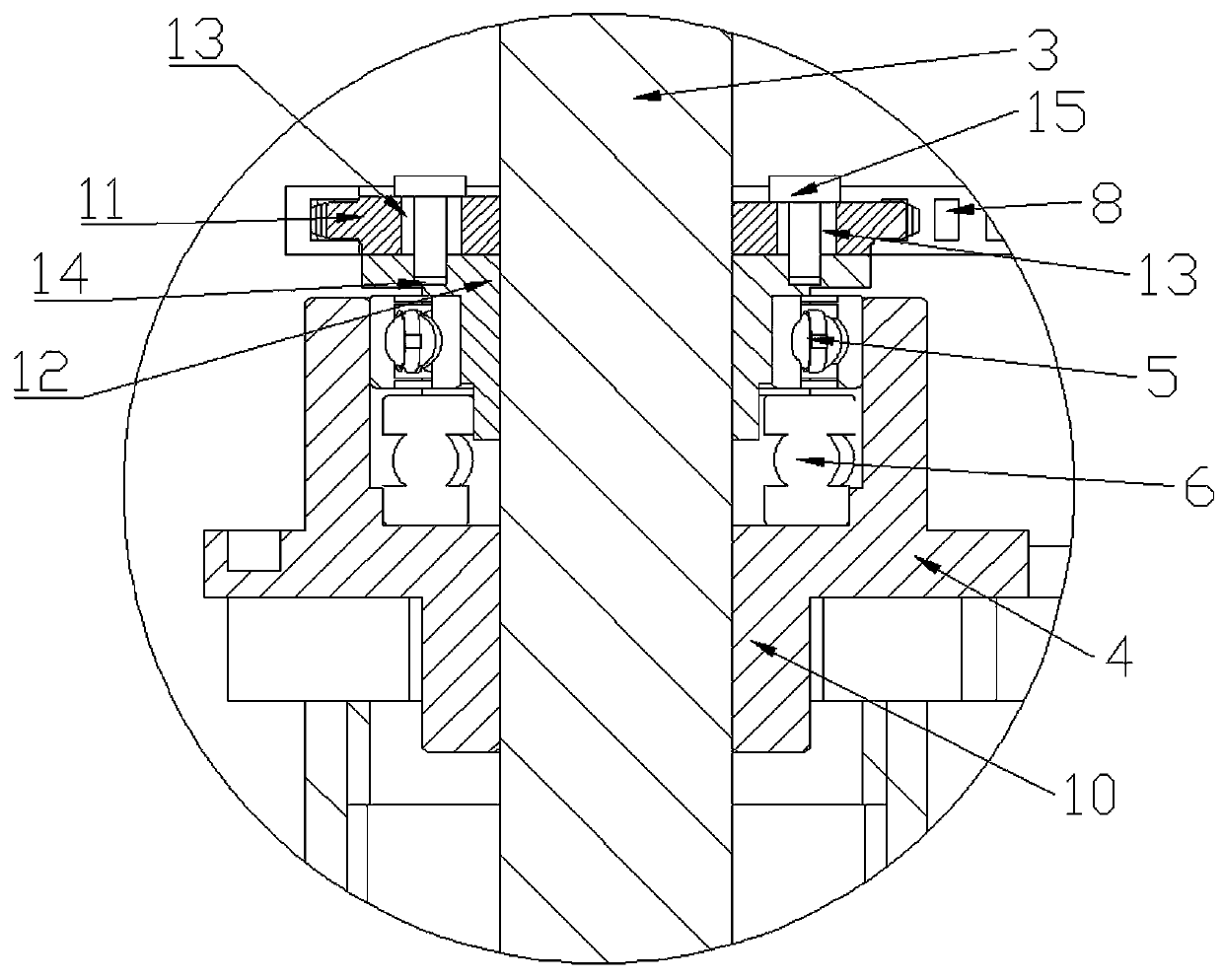

[0035] Example 1 A lifting balance adjustment mechanism for part B of a bottle making machine

[0036] In this embodiment, the power output control end of the driving part 2 is connected to the power input control end of the guide part through the transmission part, the driving part 2 transmits the power to the transmission part, and then the transmission part transmits the power to the guide part, and finally The guide plate 1 is driven up and down in balance by the guide piece. Such as Figure 1 to Figure 3 As shown, this embodiment includes a guide member, a transmission member and a drive member 2 fixed under the guide plate 1 of the B part.

[0037] The guide member is used to output the power balance of the driving member to the guide disc 1 . There are N groups of guide pieces, where N≥2. The guides can be arranged in two groups or in three groups, and the centers of the three groups of guides are located on the same circle. Preferably, there are four sets of guides...

Embodiment 2

[0042] Example 2 A lifting balance adjustment mechanism for part B of a bottle making machine

[0043] The difference between this embodiment and Embodiment 1 is that each set of guides in this embodiment is correspondingly connected with a driving member 2, and the driving member 2 directly drives the guide to go up and down, specifically:

[0044] This embodiment includes a driver 2 and at least two sets of guides fixed under the guide plate 1 of the B part of the bottle making machine. The control ends are connected, that is, the lifting and lowering of a guiding member is correspondingly controlled by a driving member 2, that is to say, there are four driving members in total. Compared with Embodiment 1, the balance lifting precision of this embodiment is higher.

Embodiment 3

[0045] Example 3 A method for adjusting the lifting balance of part B of a bottle making machine

[0046] Utilize a kind of bottle-making machine B part lifting balance adjustment mechanism in embodiment 1 to realize, comprise the following steps:

[0047] S1. Adjust the levelness of the top surface of the guide plate 1 of part B of the bottle making machine.

[0048] S11. Adjust each adjustment wheel 13 so that the top surface of the guide plate 1 of part B is placed on a horizontal plane.

[0049] S12. Install the chain on the transmission sprocket 11, loosen the adjustment groove 13 and the screw 15 in the screw hole 14 corresponding to the transmission sprocket 11 that is not engaged on the chain, and turn the transmission sprocket 11 to make the transmission sprocket 11 Engage into the links on the chain.

[0050] S13. Tighten the screw 15 on the transmission sprocket 11, and lock the transmission sprocket 11 and the corresponding adjustment wheel 13.

[0051] S2. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com