Self-cleaning flame-retardant PC resin and preparation method thereof

A self-cleaning, resin technology, applied in the field of PC resin, can solve problems such as inability to apply injection molding, inability to complete industrial production, and cumbersome steps, so as to improve the experience and quality of life, shorten the processing cycle, and optimize the processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a novel self-cleaning flame-retardant PC, the method comprising the following steps:

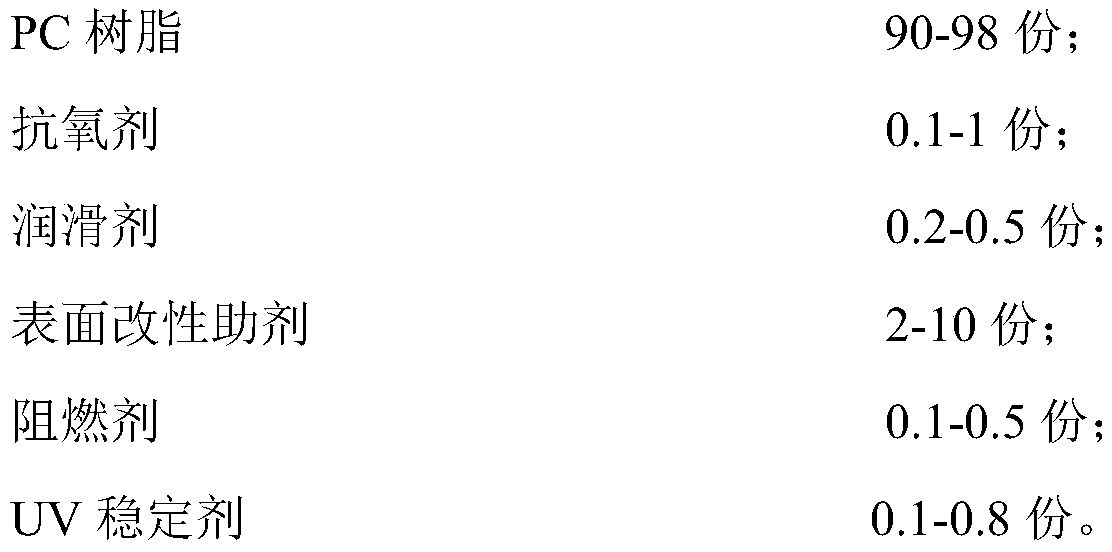

[0027] (1) Prepare materials according to the following components and parts by weight:

[0028]

[0029]

[0030] Wherein, the PC resin is mixed according to the ratio of 3:7 by two PCs with MI(300°C, 1.2kg)=4 and MI(300°C, 1.2kg)=23;

[0031] The antioxidant is Irganox 168;

[0032] The lubricant is silicone oil;

[0033] The UV stabilizer is BASF's UV-P light stabilizer;

[0034] The surface modification additive is fluorinated polyhedral oligomeric silsesquioxane (F-POSS);

[0035] The flame retardant is FR-861F of Quansheng Chemical;

[0036] (2) Put the PC resin, antioxidant, lubricant and flame retardant in the above (1) into a high-speed mixer and stir them according to the formula. After mixing evenly, send them into the twin-screw extruder through a metering device, and surface modification The auxiliary agent is sent into the twin-screw ex...

Embodiment 2

[0038] A preparation method of a novel self-cleaning flame-retardant PC, the method comprising the following steps:

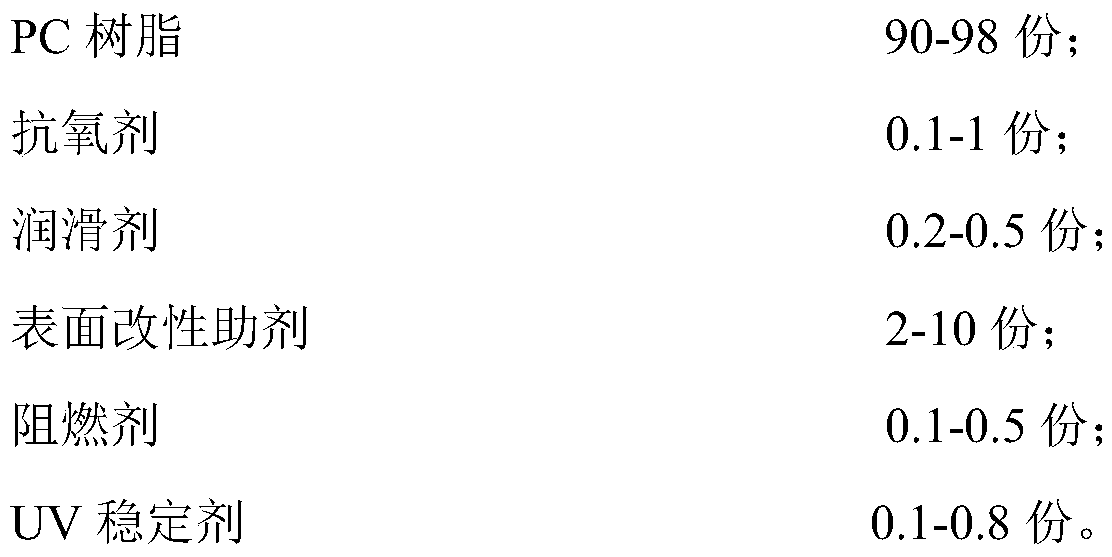

[0039] (1) Prepare materials according to the following components and parts by weight:

[0040]

[0041] Wherein, the PC resin is mixed according to the ratio of 3:7 by two PCs with MI(300°C, 1.2kg)=4 and MI(300°C, 1.2kg)=23;

[0042] The antioxidant is Irganox 168;

[0043] The lubricant is silicone oil;

[0044] The UV stabilizer is BASF's UV-P light stabilizer;

[0045] The surface modification additive is fluorinated polyhedral oligomeric silsesquioxane (F-POSS);

[0046] The flame retardant is FR-861F of Quansheng Chemical;

[0047] (2) Put the PC resin, antioxidant, lubricant and flame retardant in the above (1) into a high-speed mixer and stir them according to the formula. After mixing evenly, send them into the twin-screw extruder through a metering device, and surface modification The auxiliary agent is sent into the twin-screw extruder in th...

Embodiment 3

[0049] A preparation method of a novel self-cleaning flame-retardant PC, the method comprising the following steps:

[0050] (1) Prepare materials according to the following components and parts by weight:

[0051]

[0052] Wherein, the PC resin is mixed according to the ratio of 3:7 by two PCs with MI(300°C, 1.2kg)=4 and MI(300°C, 1.2kg)=23;

[0053] The antioxidant is Irganox 168;

[0054] The lubricant is silicone oil;

[0055] The UV stabilizer is BASF's UV-P light stabilizer;

[0056] The surface modification additive is fluorinated polyhedral oligomeric silsesquioxane (F-POSS);

[0057] The flame retardant is FR-861F of Quansheng Chemical;

[0058] (2) Put the PC resin, antioxidant, lubricant and flame retardant in the above (1) into a high-speed mixer and stir them according to the formula. After mixing evenly, send them into the twin-screw extruder through a metering device, and surface modification The auxiliary agent is sent into the twin-screw extruder in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com