Clothes folding machine and control method thereof

A control method and technology of a clothes folding machine, which are applied in the directions of folder, folding thin material, laundry room device, etc., can solve the problems of low degree of automation, large size of industrial clothes folding machine, not suitable for household use, etc., so as to save space. , The effect of ironing process intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

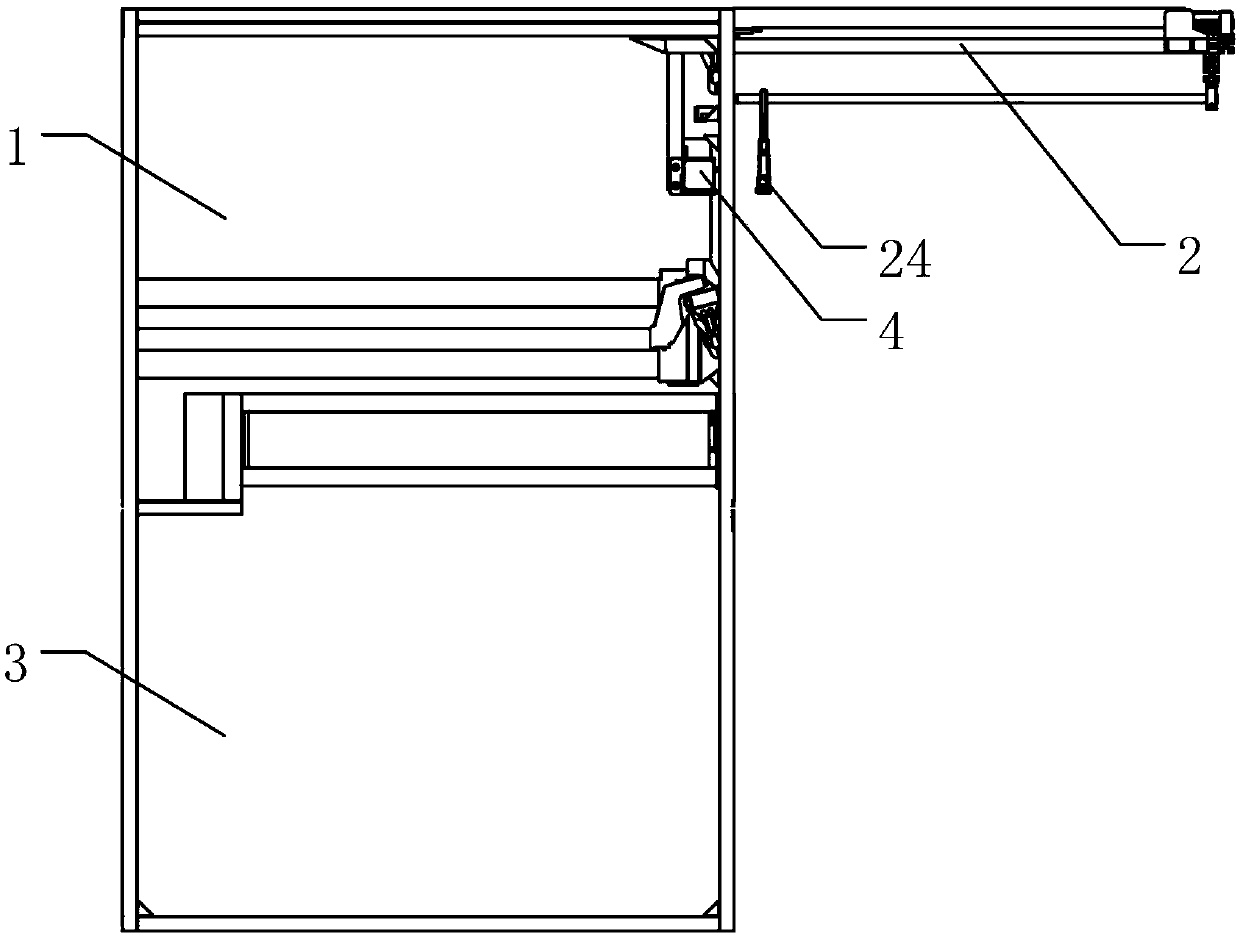

[0042] The ironing device provided by the folding machine in this embodiment is as follows: image 3 and Figure 4 shown.

[0043] The folding unit 1 of the clothes folding machine is provided with a clothes folding plate 11 for folding clothes, and the ironing device in this embodiment is a flat ironing device for ironing clothes laid flat on the clothes folding plate 11 , further, it is the first ironing device arranged at the clothing folding plate 11 .

[0044] The first ironing device sprays steam through the steam blowing holes provided on the clothes folding plate 11 to iron the clothes on the clothes folding plate 11 .

[0045] Such as Figure 4As shown, the clothes folding board 11 has a horizontal upper surface for laying clothes. When the clothes are placed on the clothes folding board 11, the first ironing device can iron the clothes, and the steam of the first ironing device The blowing holes can be evenly arranged and have a certain density. When different cl...

Embodiment 2

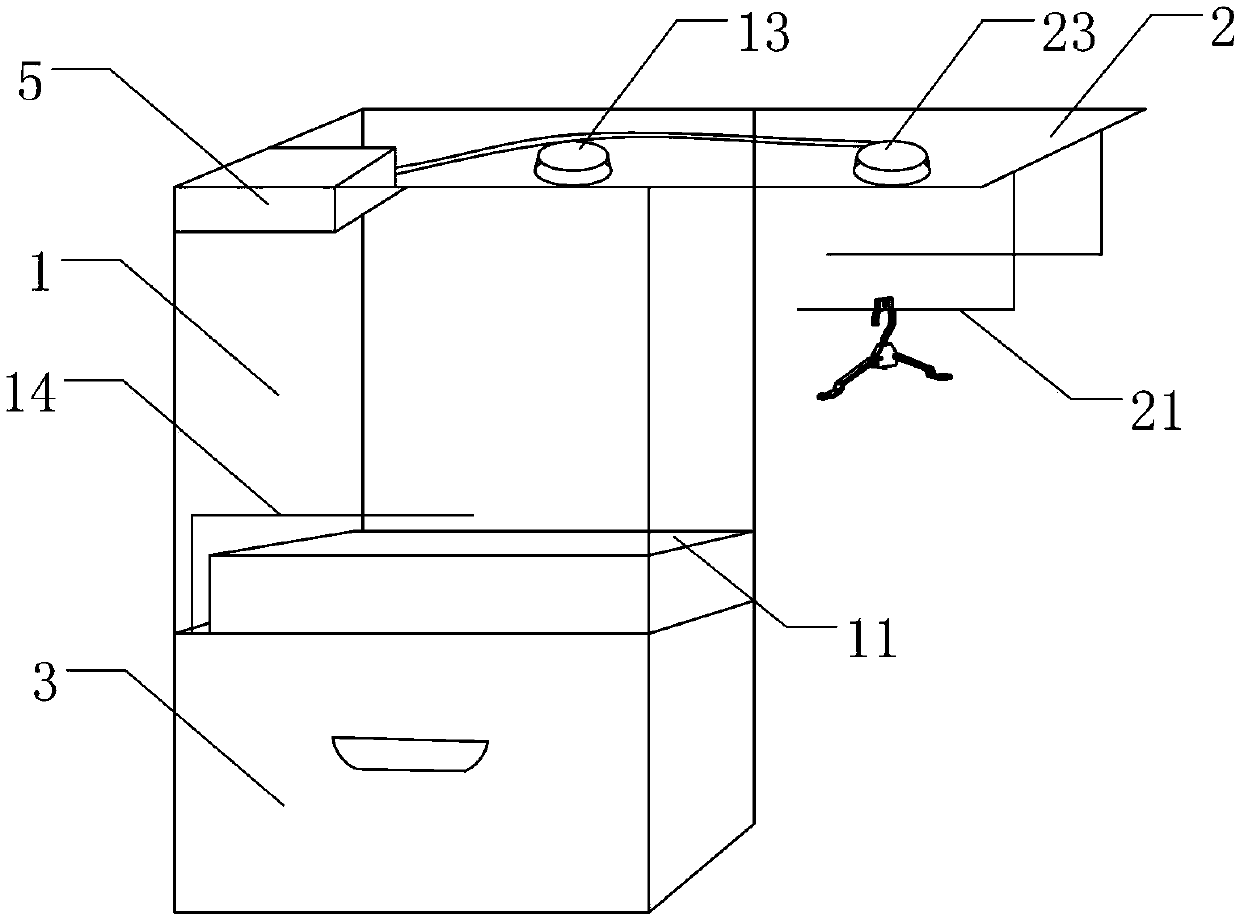

[0053] This example figure 2 As shown, the difference between this embodiment and the previous embodiment is that a second ironing device 13 is provided on the clothes folding machine.

[0054] Since the second ironing device 13 also irons the clothes in a flat state, it also belongs to an embodiment of a flat ironing device. The second ironing device 13 is arranged on the upper part of the clothes folding plate 11 and is used for ironing the upper surface of the clothes laid flat on the clothes folding plate 11 . The second ironing device 13 performs ironing by steam blowing.

[0055] The second ironing device 13 can be arranged on the top of the box at the folding unit 1, or at a position closer to the clothes folding plate 11, so that the clothes can be blown and ironed at a close distance to improve the ironing effect.

[0056] The second ironing device 13 can be a fixed device or a movable device, such as figure 2 As shown, the top of the box is provided with a steam...

Embodiment 3

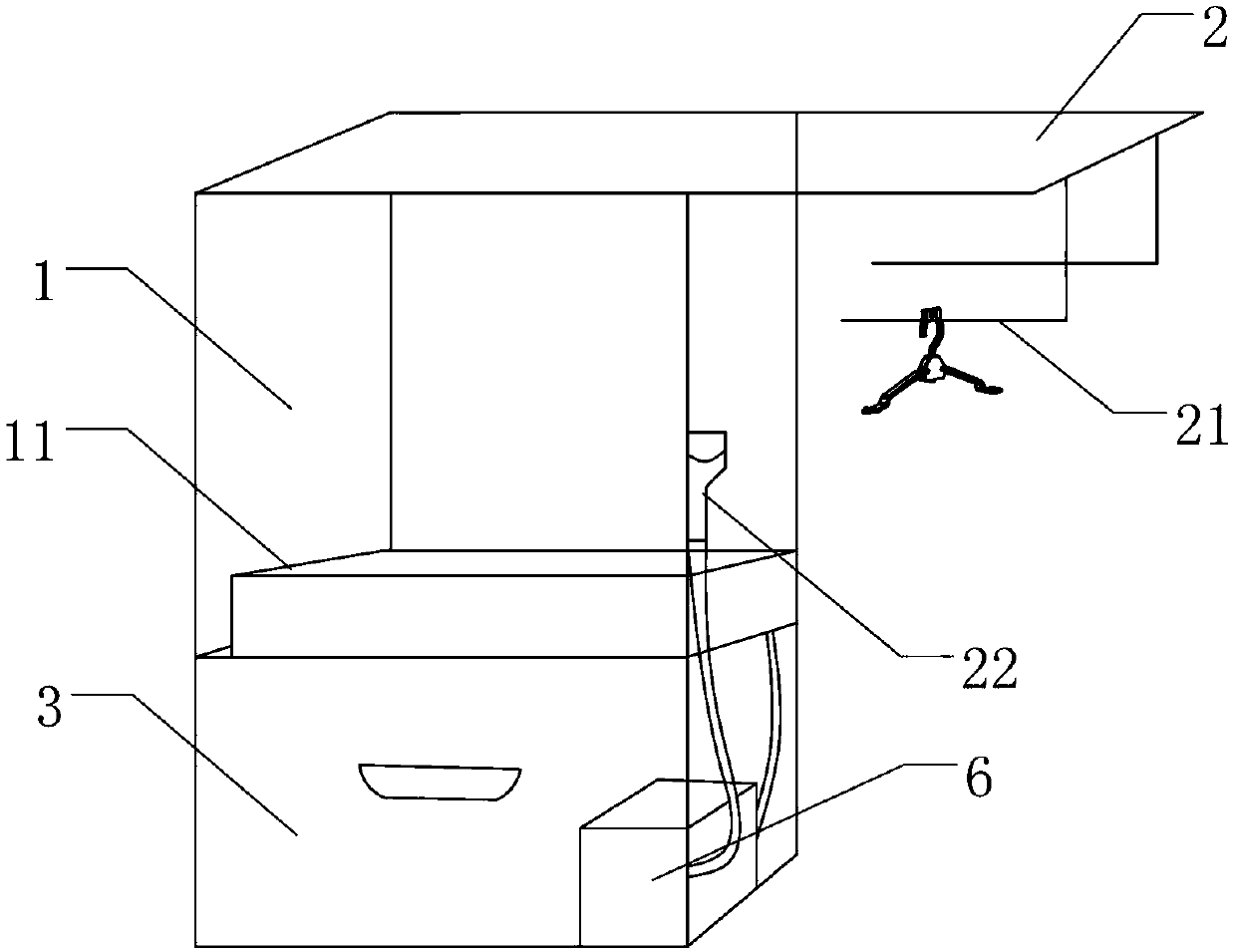

[0059] The clothes folding machine in this embodiment is provided with an ironing device, and the ironing device is arranged at the hanger conveying unit 2, and hangs and irons the hanging clothes.

[0060] The clothes hanger conveying unit 2 can be called a clothes hanging area because it is provided with a clothes hanger rod 21 to hang clothes hangers 24 .

[0061] Such as image 3 As shown, the present embodiment includes a movable ironing device. The movable ironing device can be a hand-held ironing device 22 for the user to hold and move, or an automatic ironing device that can automatically move around hanging clothes. device. Shown in the figure is a schematic view of a handheld ironing device 22 .

[0062] When the movable ironing device is a hand-held ironing device 22 , the user can turn on the ironing device by himself, and manually iron the clothes according to the folds of the clothes, so as to achieve more precise processing on the clothes. The hand-held ironi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com