Tunnel construction method for side span non-filling type long and narrow shallow-bottom karst cave section

A technology for tunnels and karst caves, which is applied in tunnels, fillings, tunnel linings, etc., can solve the problems of unsuitable long, narrow, shallow-bottomed karst caves without filling, and no treatment measures are given, and achieves extensive reference value and practical value, and safety risks. The effect of low and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

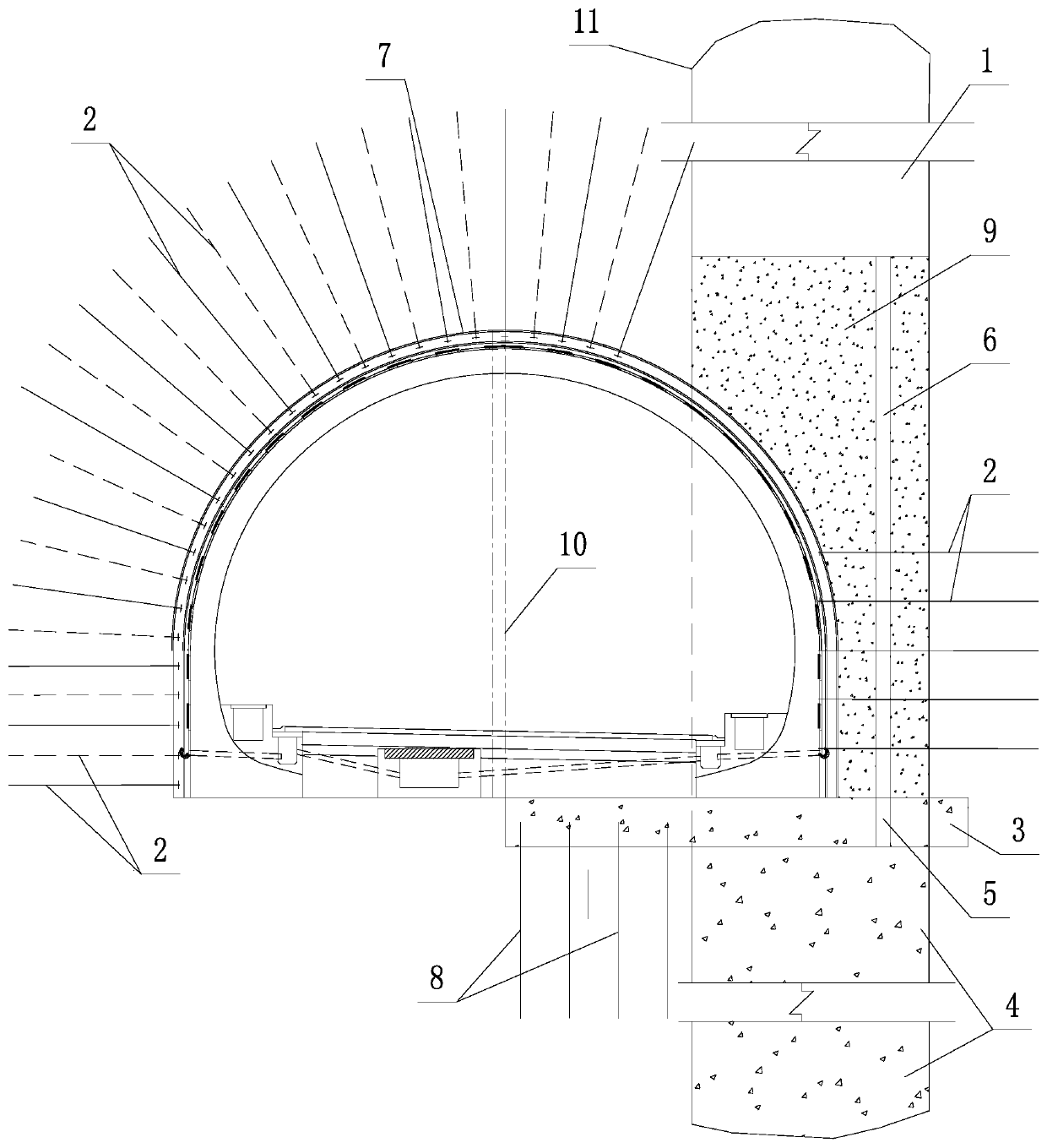

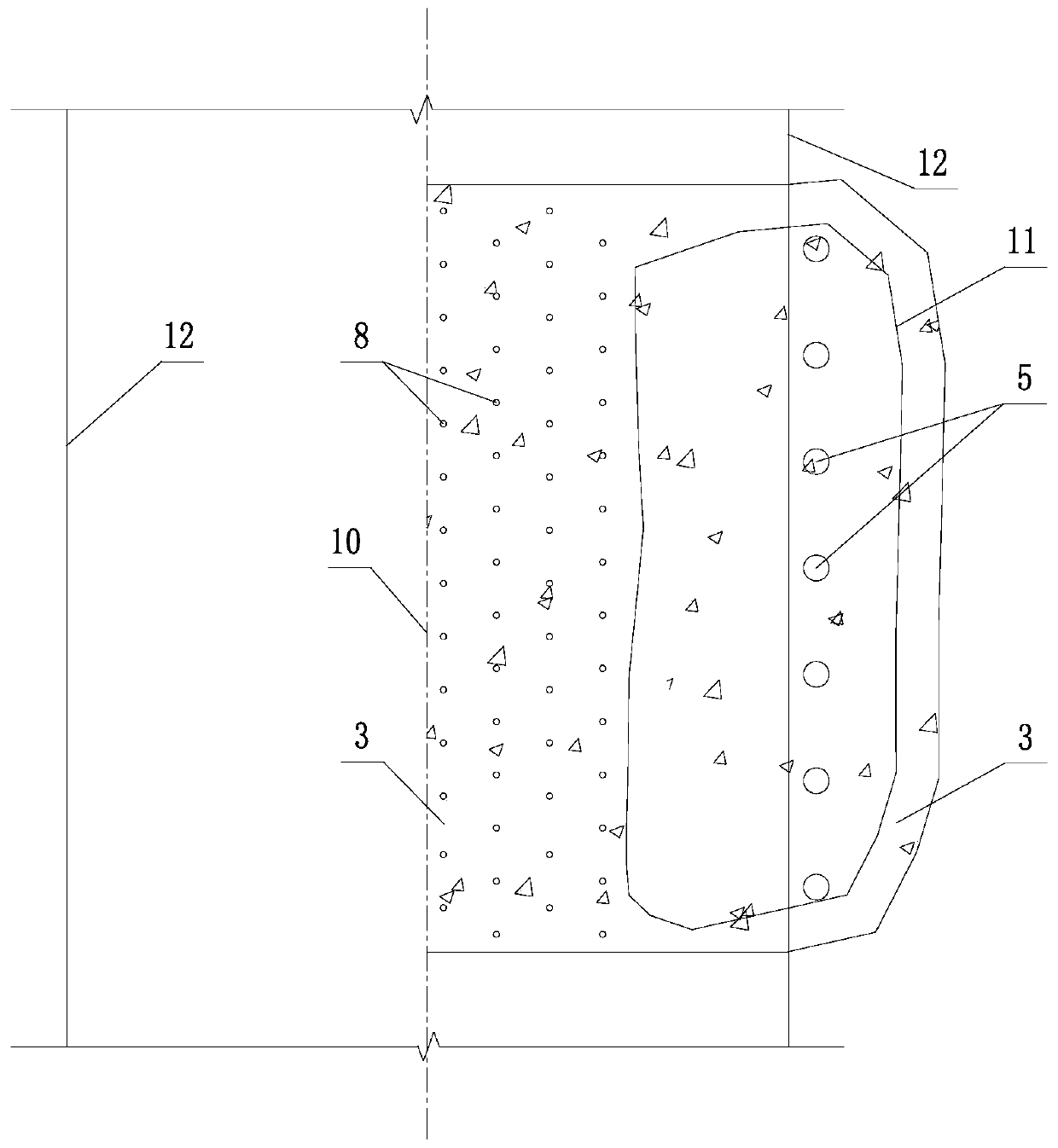

[0036] The unfilled narrow, long, shallow-bottomed karst cave in practice refers to: in the plan view, the karst cave is located on one side of the tunnel, part of the karst cave extends into the tunnel, and the direction of the karst cave intersects with the direction of the line at a small angle (greater than 0°, less than 30°) or Parallel to the line, the karst cave is in the shape of a long strip, the longitudinal length of the karst cave is not less than 3m, the width is 1-5m, and the karst cave invades the tunnel by 1-5m. In the longitudinal section, the height difference between the top of the cave and the road surface is more than 20m, the depth of the bottom of the cave to the road surface is not more than 60m, and the wall of the cave is basically vertical; the cave rocks are horizontally layered, thin to medium-thick, soft and hard interbedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com