Three-step inverted arch synchronous excavation and support construction method for soft surrounding rock tunnel

A technology with weak surrounding rocks and construction methods, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of slow construction progress, many processes, and late initial support ring formation, etc., to achieve fast construction progress and simple operation techniques , The effect of simplifying the process of building and excavating transportation channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

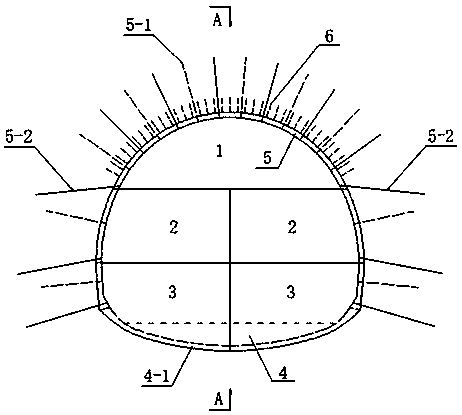

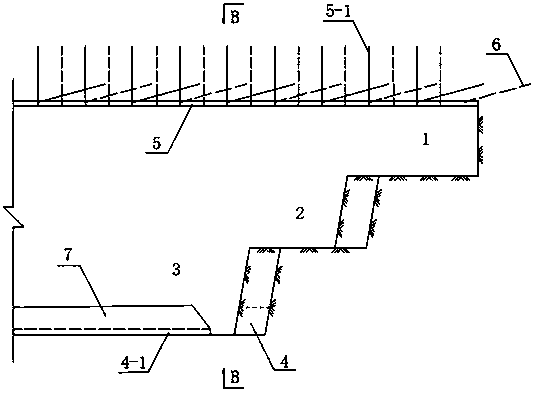

[0024] A construction method for synchronous excavation and support of three steps with inverted arches in a tunnel with weak surrounding rock. The step excavation includes an inverted arch section. Each step forms a relatively independent work space, and does not interfere with each other during excavation and support. Specifically, it includes three major steps:

[0025] The first major step is the excavation step: each step is drilled at the same time, charged and wired at the same time, and detonated in the order of upper, middle and lower. The second major step is the support step: the initial support construction of the arch wall such as slag removal and installation of steel frames on the upper steps and advance support; the slag removal and installation of steel frames on the middle steps, lower steps, and inverted arches in sequence construction. The third major step is the spraying step: the inverted arch, the lower step, the middle step, and the upper step are sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com