Packaging component of self-sensing reinforcing steel bar

A self-sensing, steel bar technology, applied in measuring devices, measuring force by measuring the change of optical properties of materials under stress, instruments, etc., can solve problems such as easy breakage and low shear resistance, and achieve low energy loss. , It is not easy to break, and the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

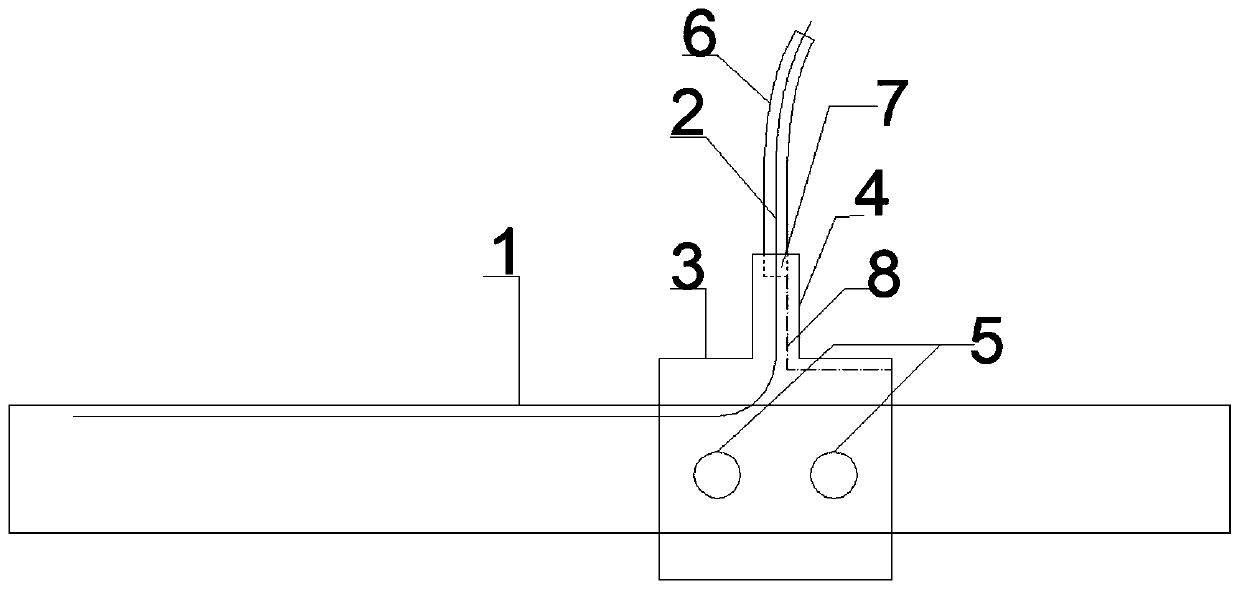

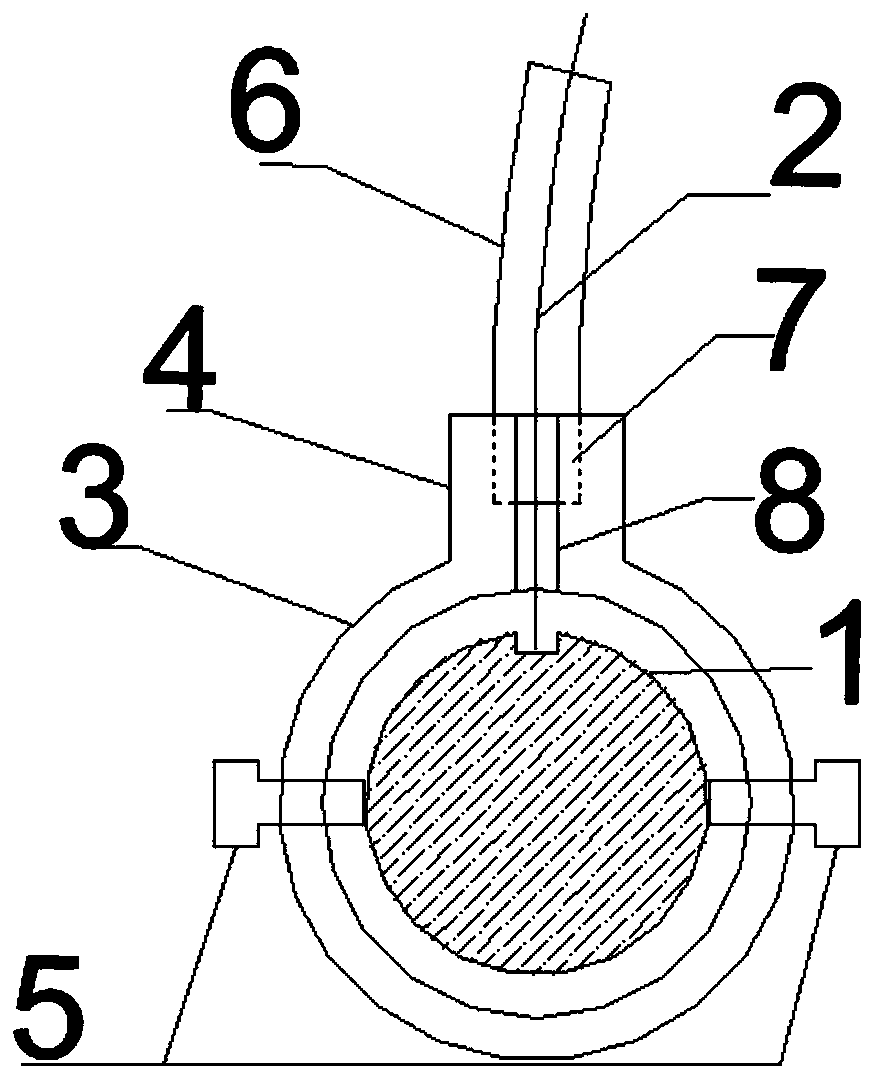

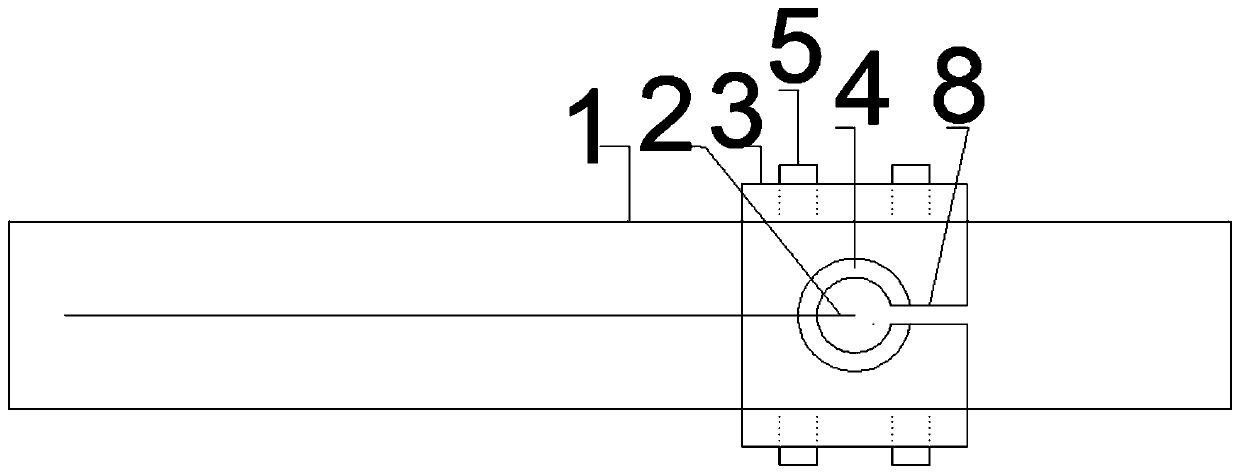

[0016] Such as figure 1 , 2 As shown in , 3, a packaging component of a self-sensing steel bar embedded with a fiber grating is used to protect the lead-out line of the self-sensing steel bar embedded with a fiber grating, including a self-sensing steel bar 1, an optical fiber lead-out line 2, and a packaging component 3 And the protective tube 6. The encapsulation component 3 covers the lead-out position of the embedded fiber grating self-sensing steel bar in its own internal space, protecting it from impact and resulting in brittle fracture. The protection tube 6 is closely connected with the packaging component 3, and the protection tube wraps the pigtail of the lead-out line outside the internal lead-out engineering component.

[0017] The packaging component 3 includes: an extraction hole 4 , a tightening screw 5 and a cutout 8 . Screw holes are provided on both sides of the package member 3, and the screw 5 is tightened to fix the package member 3 on the self-sensing ...

specific Embodiment 2

[0021] Such as Figure 4 , 5 , shown in 6, a packaging component of a carbon plate embedded with a fiber grating, used to protect the lead-out line of the carbon plate embedded with a fiber grating, including a carbon plate 1, an optical fiber lead-out line 2, a package component 3 and a protection tube 6. The packaging component 3 covers the lead-out wires embedded in the fiber grating carbon plate in its own internal space, protecting it from shocks and brittle fractures. The protection tube 6 is tightly connected with the packaging component 3, and the protection tube wraps the pigtail of the lead-out line outside the internal lead-out engineering component.

[0022] The packaging component 3 includes: an extraction hole 4 , a tightening screw 5 and a cutout 8 . Holes are provided on both sides of the packaging component 3, and the screw 5 is tightened to fix the packaging component 3 on the engineering component and ensure that the cutout 8 and the lead-out hole 4 are l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com