Pole piece for button cell, button cell and preparation method of button cell

A button battery, pole piece technology, applied in secondary battery manufacturing, battery pack parts, winding/folding electrodes, etc. , Reduce the difficulty of the process and increase the effect of the effective use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

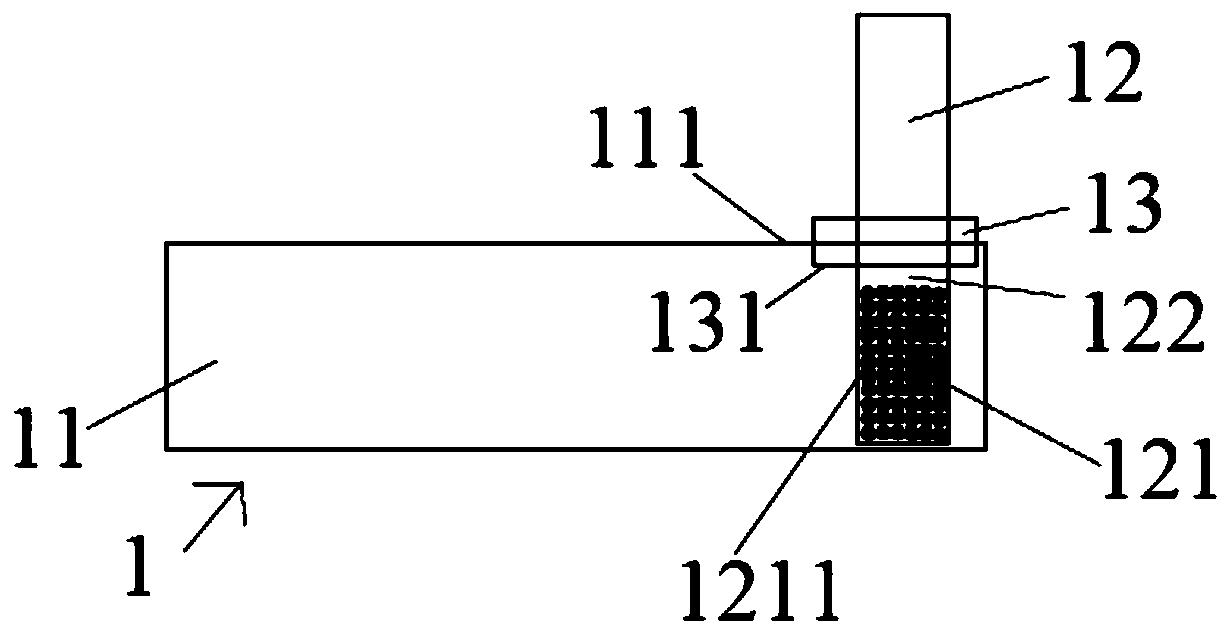

[0042] Such as figure 2 As shown, a button battery pole piece, including:

[0043] Current collector 11;

[0044] The tab 12 is provided with a tab glue 13, and one end of the tab 12 has a welding area 121, and the tab 12 is welded to the current collector 11 through the welding area 121;

[0045] Wherein, at least a part of the tab glue 13 overlaps with the current collector 11 , and a bendable flexible portion 122 is formed between the welding area 121 and the tab glue 13 .

[0046] Furthermore, laser welding or ultrasonic welding can be used for welding the tab 12 and the current collector 11 , preferably ultrasonic welding is used to control the size of the welding spot 1211 more precisely. The tab glue 13 can partially overlap with the current collector 11 or fully overlap with the current collector 11. It is only necessary to ensure that the subsequent tab glue 13 can be extended to the seal of the aluminum-plastic film to play the role of insulation; preferably, Pre...

Embodiment 2

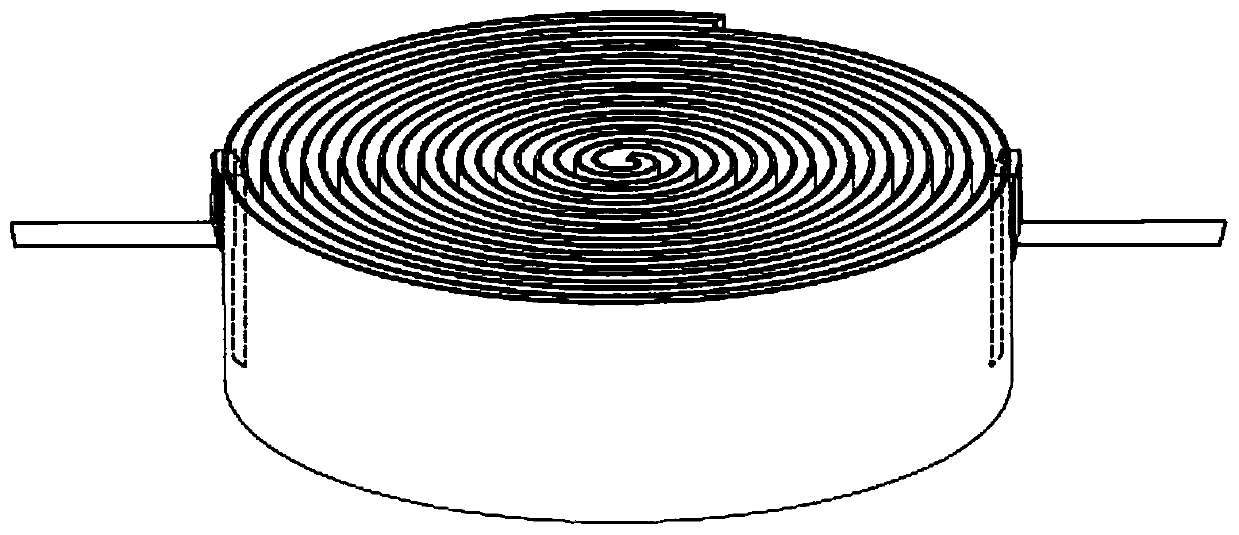

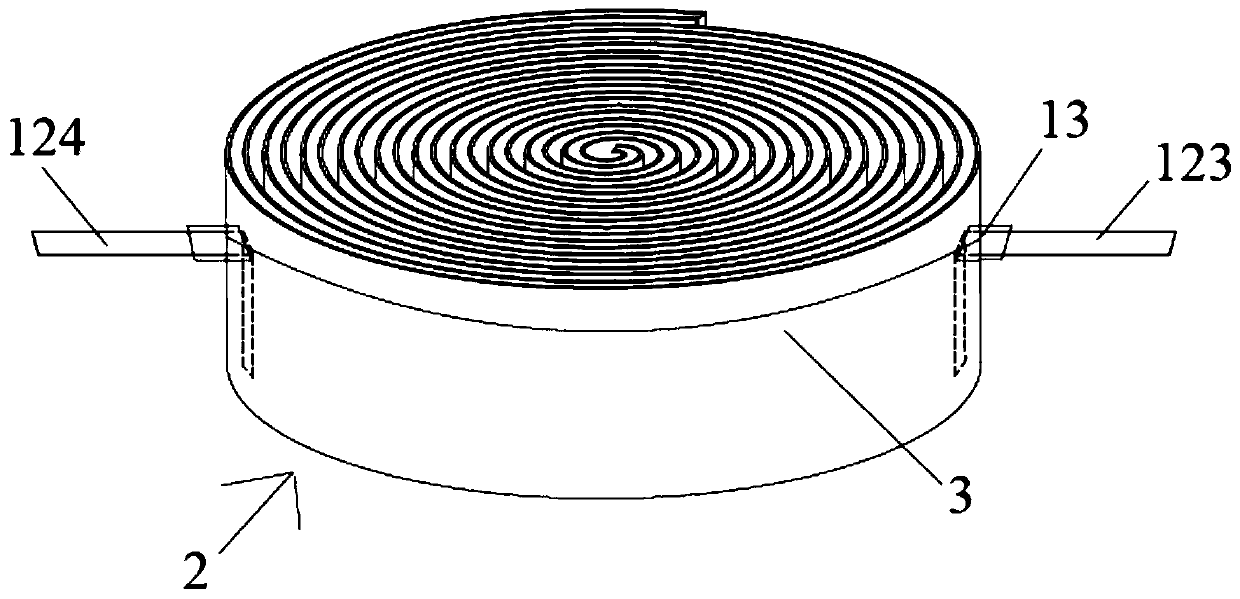

[0050] Such as Figure 3-5 As shown, a button battery includes a cell 2 wound from the pole piece 1 described in Example 1 and an aluminum-plastic film wrapped outside the cell 2, the aluminum-plastic film includes a first aluminum-plastic film and a second aluminum-plastic film Two aluminum-plastic diaphragms, the tab 12 is horizontally bent by the flexible part 122 and extends outward along the joint of the first aluminum-plastic diaphragm and the second aluminum-plastic diaphragm. Among them, the shape settings of the first aluminum-plastic diaphragm and the second aluminum-plastic diaphragm of the aluminum-plastic film can be adapted and changed according to the shape of the button battery, such as round or square, but it should be ensured that the first aluminum-plastic diaphragm and the second aluminum-plastic diaphragm The aluminum-plastic diaphragm is matched to meet the requirements of the subsequent packaging cell.

[0051] Preferably, the distance between the outwa...

Embodiment 3

[0055] The present embodiment provides a kind of preparation method of button battery, comprises the following steps:

[0056] S1, welding the tab 12 to the current collector 11 through the welding area 121;

[0057] S2, apply the tab glue 13 on the tab 12 and close to the welding area 121, make at least a part of the tab glue 13 overlap with the current collector 11, and reserve a flexible part 122 between the welding area 121 and the tab glue 13;

[0058] S3, punching the first aluminum-plastic diaphragm and the second aluminum-plastic diaphragm respectively;

[0059] S4. Place the battery cell 2 in the pit of the second aluminum-plastic diaphragm, and then cover the first aluminum-plastic diaphragm along the direction of the second aluminum-plastic diaphragm, so that the tab is bent horizontally by the flexible part 122 and Extending outward along the joint of the first aluminum-plastic film and the second aluminum-plastic film to complete the packaging of the aluminum-pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com