A non-jet atmospheric pressure large-volume microwave plasma generation method

A microwave plasma and plasma technology, applied in the field of plasma, can solve problems such as side reactions, unstable operation, and increased separation burden of subsequent devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

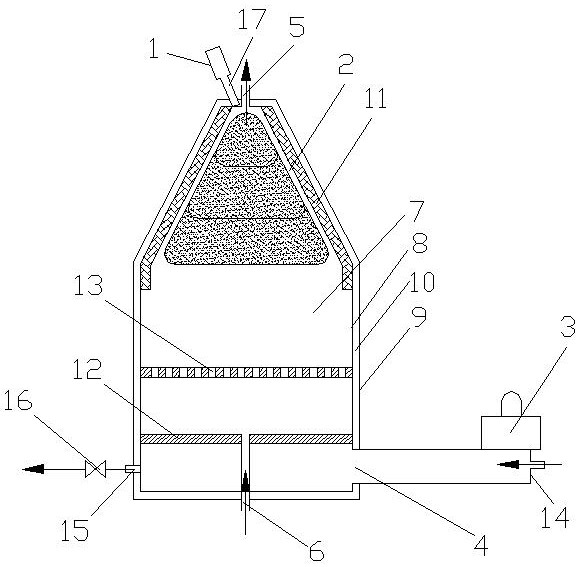

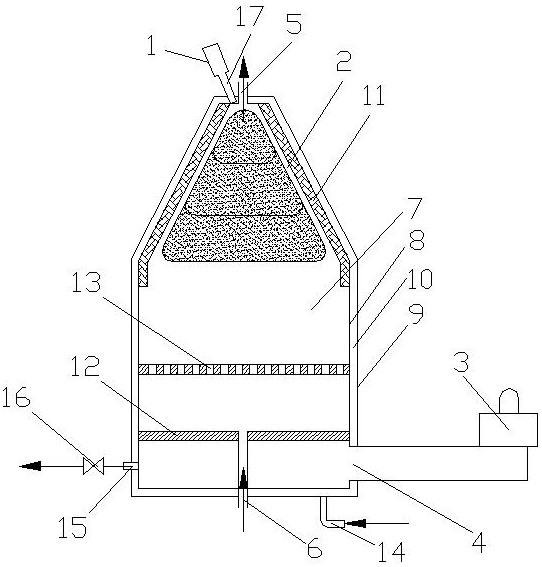

[0050] A non-jet atmospheric pressure large-volume microwave plasma generation method, comprising the following steps:

[0051] a. Start the igniter 1, and spray the generated small plasma or chemical flame into the conical cavity 2 from the ignition channel 17 on the reaction chamber of the plasma generator;

[0052] b. Start the microwave source 3, input microwaves into the reaction chamber through the microwave feed port 4, and the microwaves act on the small plasma or chemical flame, so that the microwave energy provided by the microwave source is obtained on the small plasma or chemical flame, and is converted into stable Small microwave plasma, which is concentrated on the top of the conical cavity 2;

[0053] c. Turn off the igniter 1, increase the microwave power of the microwave source 3, and the small plasma in the conical cavity 2 is amplified to obtain non-jet, normal pressure high power and large volume microwave plasma.

[0054] This embodiment is the most basic...

Embodiment 2

[0056] A non-jet atmospheric pressure large-volume microwave plasma generation method, comprising the following steps:

[0057] a. Start the igniter 1, and spray the generated small plasma or chemical flame into the conical cavity 2 from the ignition channel 17 on the reaction chamber of the plasma generator;

[0058] b. Start the microwave source 3, input microwaves into the reaction chamber through the microwave feed port 4, and the microwaves act on the small plasma or chemical flame, so that the microwave energy provided by the microwave source is obtained on the small plasma or chemical flame, and is converted into stable Small microwave plasma, which is concentrated on the top of the conical cavity 2;

[0059] c. Turn off the igniter 1, increase the microwave power of the microwave source 3, and the small plasma in the conical cavity 2 is amplified to obtain non-jet, normal pressure high power and large volume microwave plasma.

[0060] It also includes step d, by feedi...

Embodiment 3

[0064] A non-jet atmospheric pressure large-volume microwave plasma generation method, comprising the following steps:

[0065] a. Start the igniter 1, and spray the generated small plasma or chemical flame into the conical cavity 2 from the ignition channel 17 on the reaction chamber of the plasma generator;

[0066] b. Start the microwave source 3, input microwaves into the reaction chamber through the microwave feed port 4, and the microwaves act on the small plasma or chemical flame, so that the microwave energy provided by the microwave source is obtained on the small plasma or chemical flame, and is converted into stable Small microwave plasma, which is concentrated on the top of the conical cavity 2;

[0067] c. Turn off the igniter 1, increase the microwave power of the microwave source 3, and the small plasma in the conical cavity 2 is amplified to obtain non-jet, normal pressure high power and large volume microwave plasma.

[0068] It also includes step d, by feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com