Method for improving processing effect of surface coated with paper matte lamination film

A technology for surface treatment and paper, applied in the field of improving the surface treatment effect of coated paper matte lamination, can solve the problems of low color saturation, low contrast, loss of details, etc., to achieve improved saturation, improved details, and overall color saturation improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention discloses a method for improving the surface treatment effect of coated paper dumb coating, which comprises the following steps:

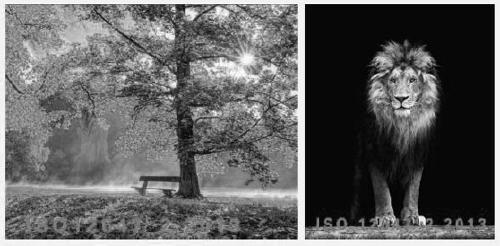

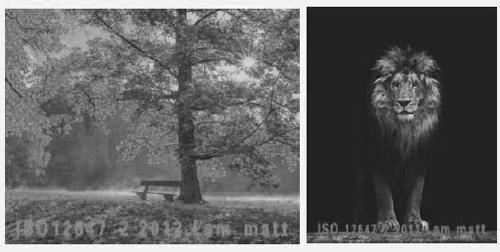

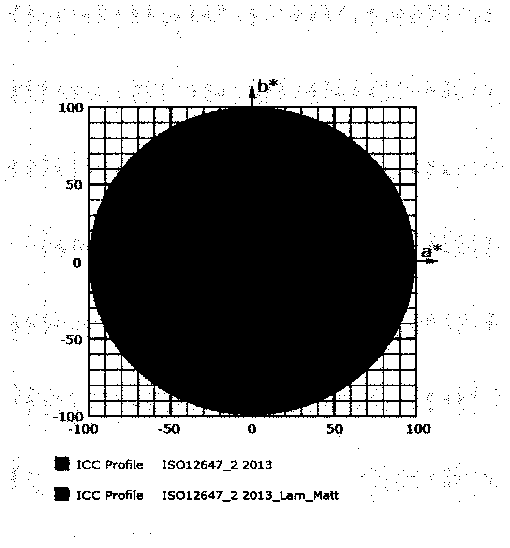

[0036](1) Improve saturation: increase the target value of each primary color of the printed sheet before surface treatment; the color target data is as follows: Black L7.0 a 0.0 b 0.0 Blue L 48.0 a -31.0 b -60.0 Red L 45.0 a 85.0 b 4.0 Yellow L 89.5a -3.0 b 120; ISO 12647-2 2013 target data are as follows: black L 16.0 a 0.1 b -0.3 blue L 56.0a -34.9 b -52.5 red L 48.1 a 75.3 b -5.2 yellow L 88.9 a -4.0 b 92.4. The actual printed sheet effect comparison is as follows Figure 5 shown, and from Image 6 It can be seen that the blue line represents the ISO12647-2 (2013) standard color gamut; the red line represents the color gamut of the ISO12647-2 (2013) standard printed sheet after the matte film is covered; the yellow line represents the color of the Multicolor printed sheet after the matte film is covered Gamut; From the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com