Bottle unscrambler device applied to nuclear waste liquid sample bottles

A bottle unscrambler and sample bottle technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of affecting efficiency and health risks, slow manual operation, and low degree of automation, so as to improve labor production. Efficiency, easy operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

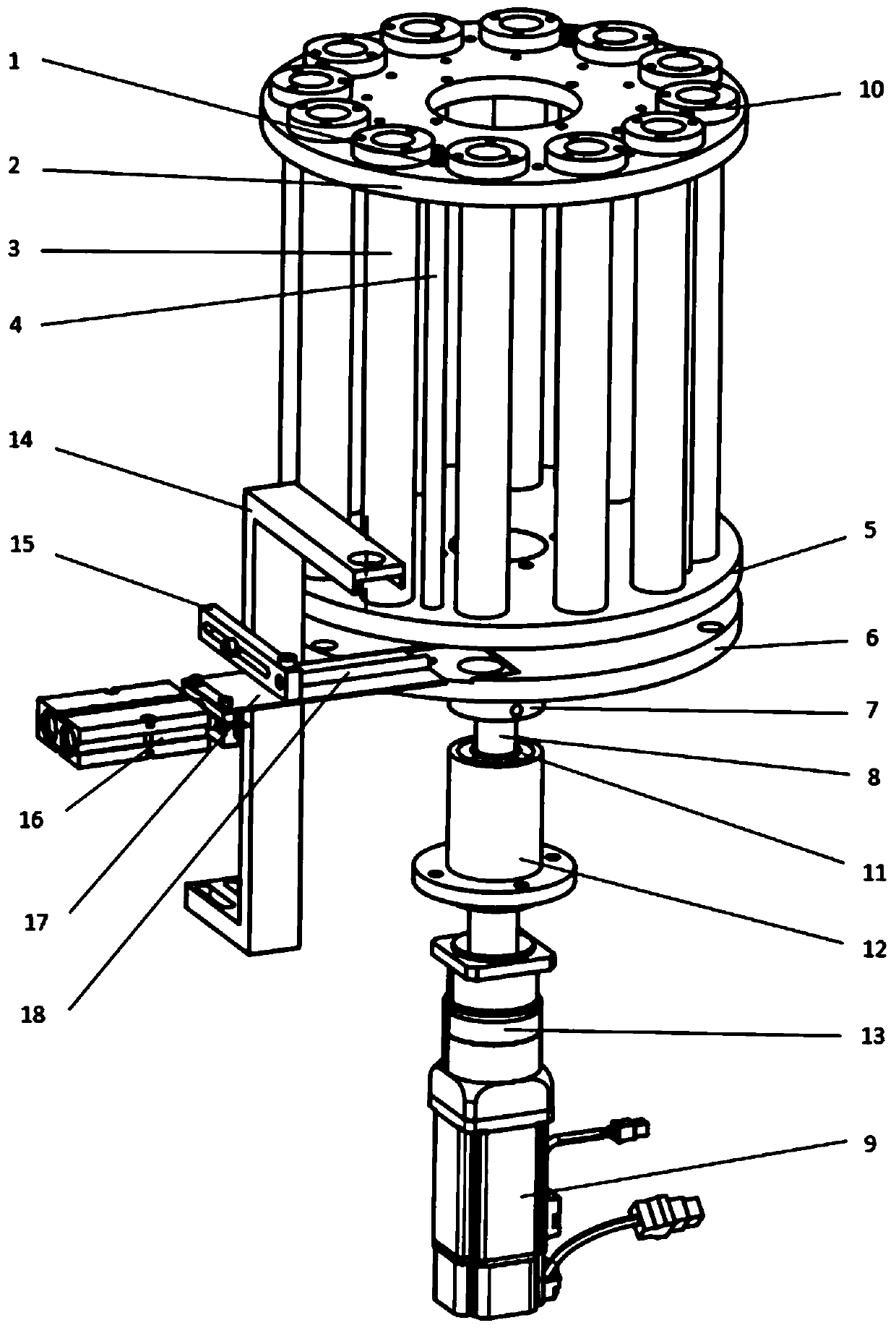

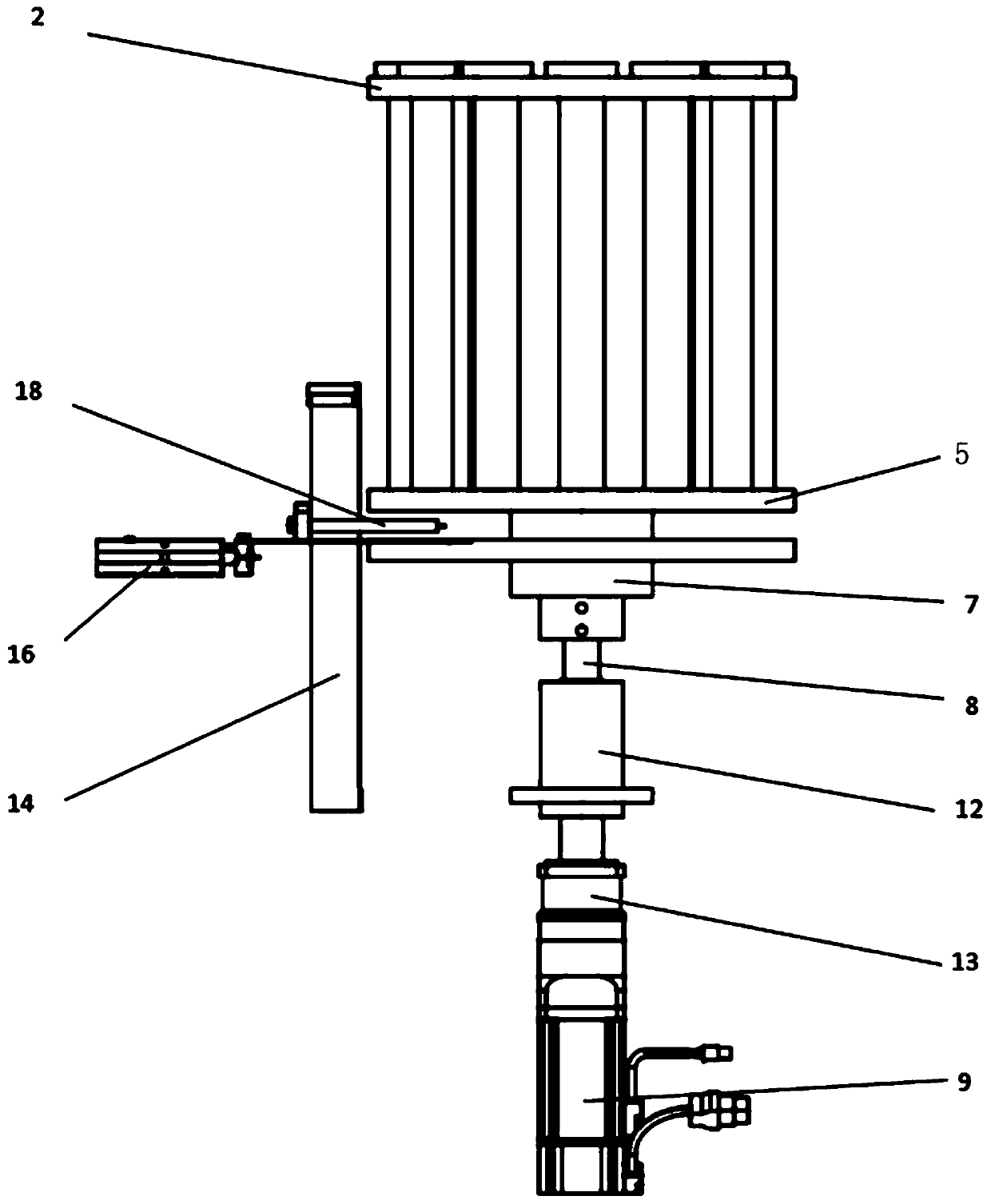

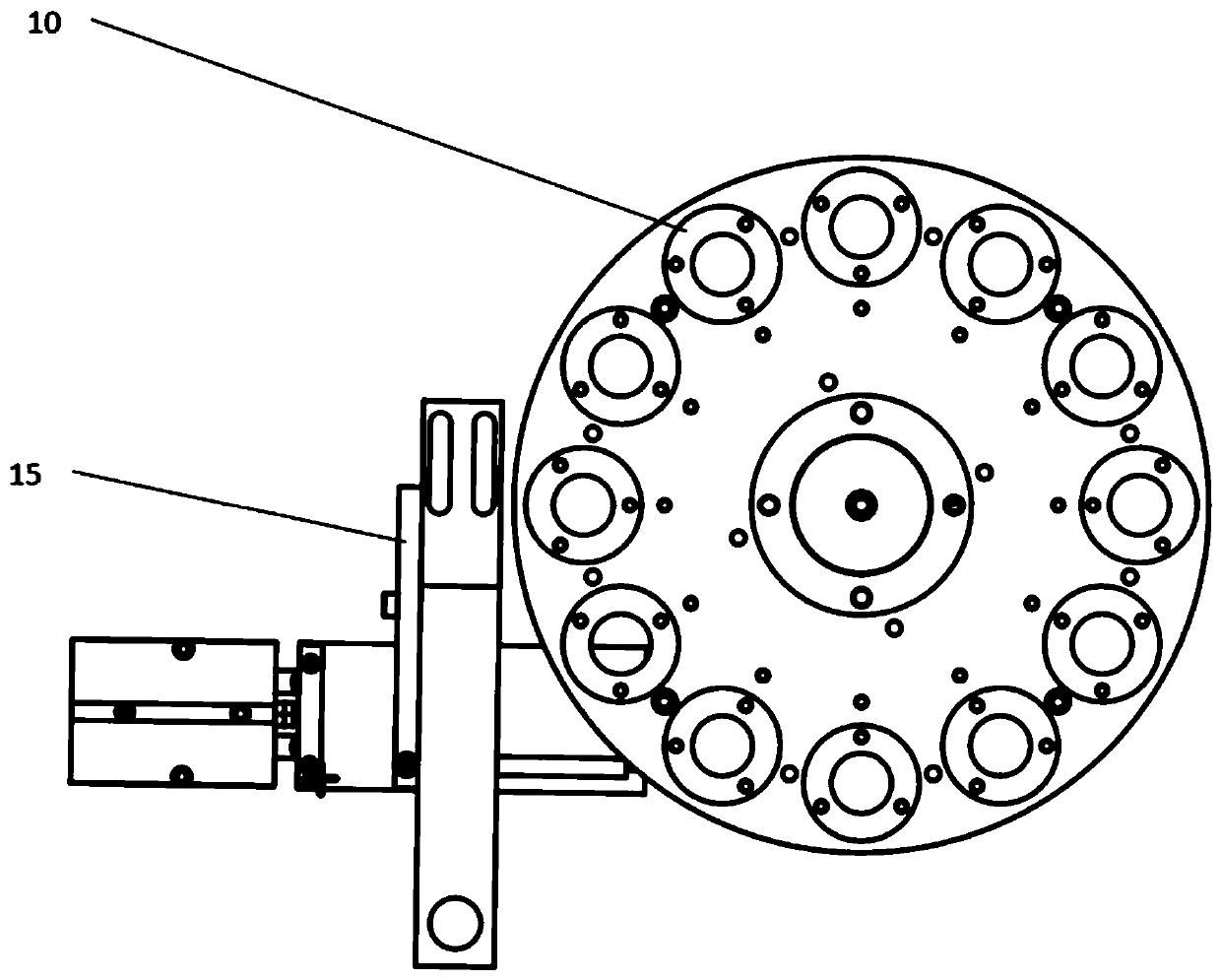

[0029] The invention discloses a bottle unscrambler device applied to nuclear waste liquid sample bottles. Bottle machine turntable bottom support 7, bottle unscrambler rotating shaft 8, servo motor 9 and planetary reducer 13; bottle unscrambler upper cover 2 and bottle unscrambler lower cover 5 are in the shape of a ring, and their specifications are exactly the same. 4 threaded rods 4 are fixedly connected, the threaded rods 4 are rod-shaped, and threads are provided at both ends, and a gasket 1 is provided at the connection between the threaded rods 4 and the upper cover 2 of the bottle unscrambler, which is used to increase the contact between the nut and the upper cover of the bottle unscrambler Area, protect bottle unscrambler upper cover 2; The circular surface of bottle unscrambler upper cover 2 and bottle unscrambler lower cover 5 is respectively provided with equal numbers of circular holes evenly distributed on the same circumference, and bottle unscrambler upper and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap