Screen beneath camera attaching and assembling equipment

A technology for assembling equipment and cameras, applied in mechanical equipment, packaging, material gluing, etc., can solve the problem of not eliminating the position on the camera screen film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Embodiment 1: the concrete structure of the present invention is as follows:

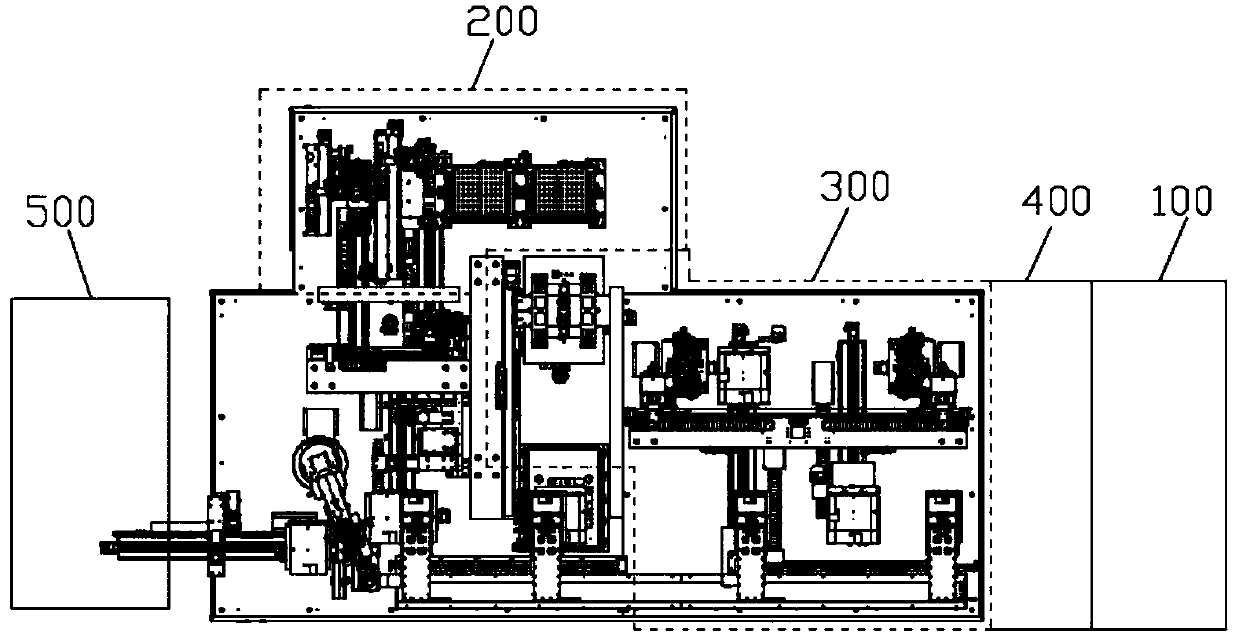

[0116] Please refer to the attached figure 1 , an under-display camera fitting and assembling device of the present invention includes a mobile phone screen loading device 500, and an organic platform is arranged on the adjacent side of the mobile phone screen feeding device 500, and is characterized in that the under-screen camera fitting and assembling device is also include:

[0117] The mobile phone screen retrieving manipulator is arranged on the machine table and placed on the mobile phone screen discharge station of the mobile phone screen feeding device 500, which is used to take out the mobile phone screen and send it to the cleaning tearing film area, and the cleaning tearing film area After the mobile phone screen is cleaned and torn off, it is sent to the ultrasonic cleaning area by the manipulator;

[0118] Fully automatic bonding structure of optical glue 200 [please refer to ...

Embodiment 2

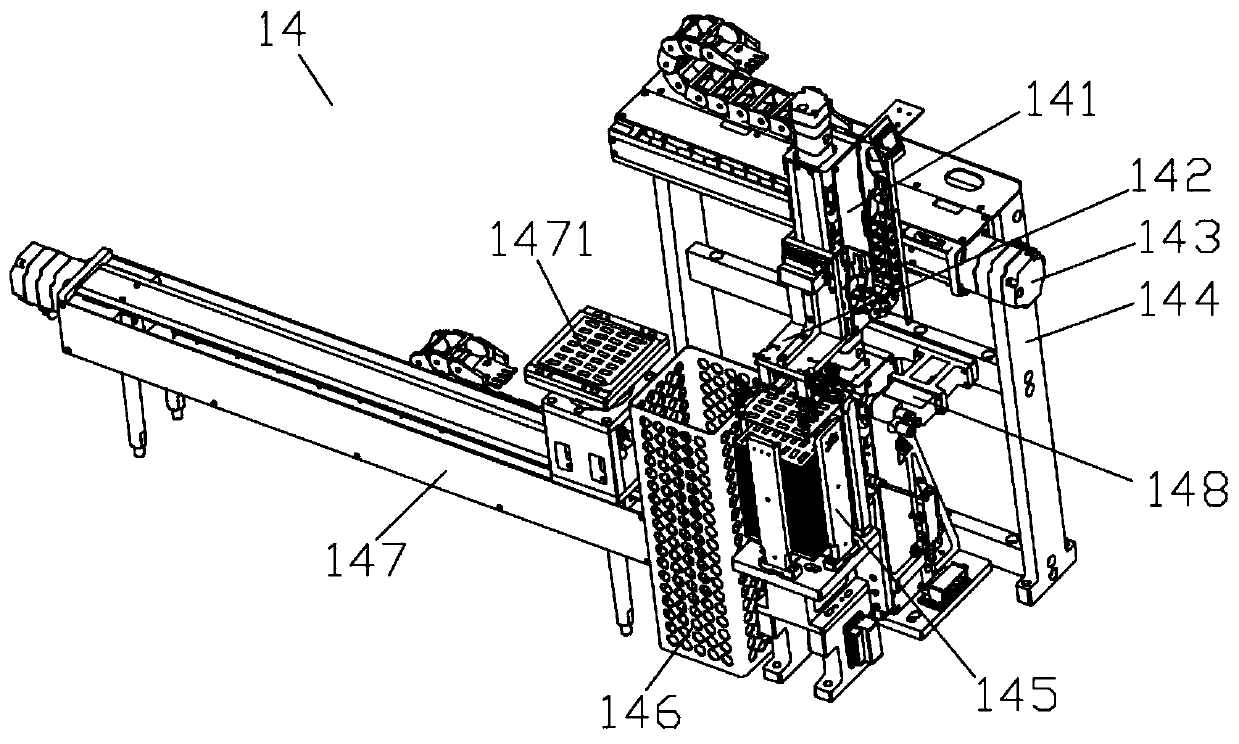

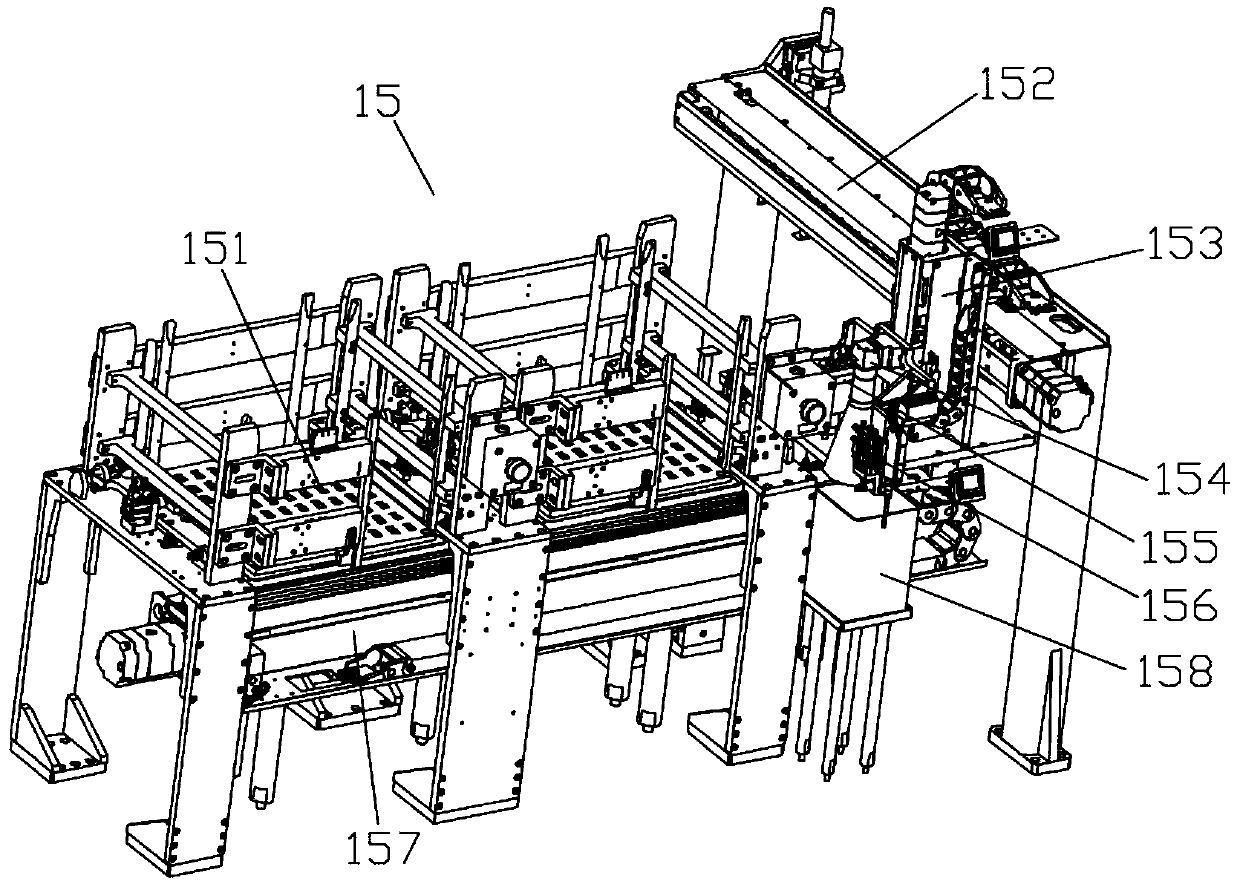

[0123] [Please refer to the attached Figure 2-8 ], the following is the specific structure of the fully automatic bonding structure 200 of optical glue:

[0124] The OCA optical glue feeding area 145 includes:

[0125] first support;

[0126] Several baffles installed around the upper plane plate of the first support, the several baffles enclose the stacking cavity of OCA optical glue, and the position of each baffle can be adjusted;

[0127] The OCA turntable mechanism 147 includes a linear drive mechanism and a first adsorption device 1471 installed on the moving part of the linear drive mechanism. The power source of the linear drive mechanism is a first motor, and the driving end of the first motor is connected to the first motor. A threaded rod, which drives the first adsorption device 1471 to perform linear motion by driving the rotation of the first threaded rod;

[0128] The upper end of the first adsorption device 1471 is a platform for loading OCA optical glue. The...

Embodiment 3

[0162] The operating principle of the fully automatic laminating mechanism of the present invention is as follows:

[0163] [Please refer to the attached Figure 2-8 ], OCA optical adhesive feeding mechanism 14 is used for OCA optical adhesive feeding, and the OCA take-and-place tearing film mechanism on it first absorbs the heavy film through the suction cup, and the OCA optical adhesive is automatically separated from the light film, and then the OCA optical adhesive is transported to On the platform of the first adsorption device 1471, the negative pressure of the first adsorption device 1471 sucks the lower surface of the OCA optical glue, its adsorption force is greater than the adhesive force of the heavy film, and the Z-axis mechanism on the OCA pick-and-place tearing mechanism lifts the heavy film It is torn off and fed into the sheet film placement box 146 . The OCA turntable mechanism 147 sends the OCA optical glue without heavy film and light film into the assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com