Steam turbine flow characteristic optimization method based on full-stroke modeling

A technology of flow characteristics and optimization methods, which is applied in the direction of flow control, flow control of electric devices, mechanical equipment, etc., and can solve problems such as the inability to realize the optimization of flow characteristics in the flow command interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

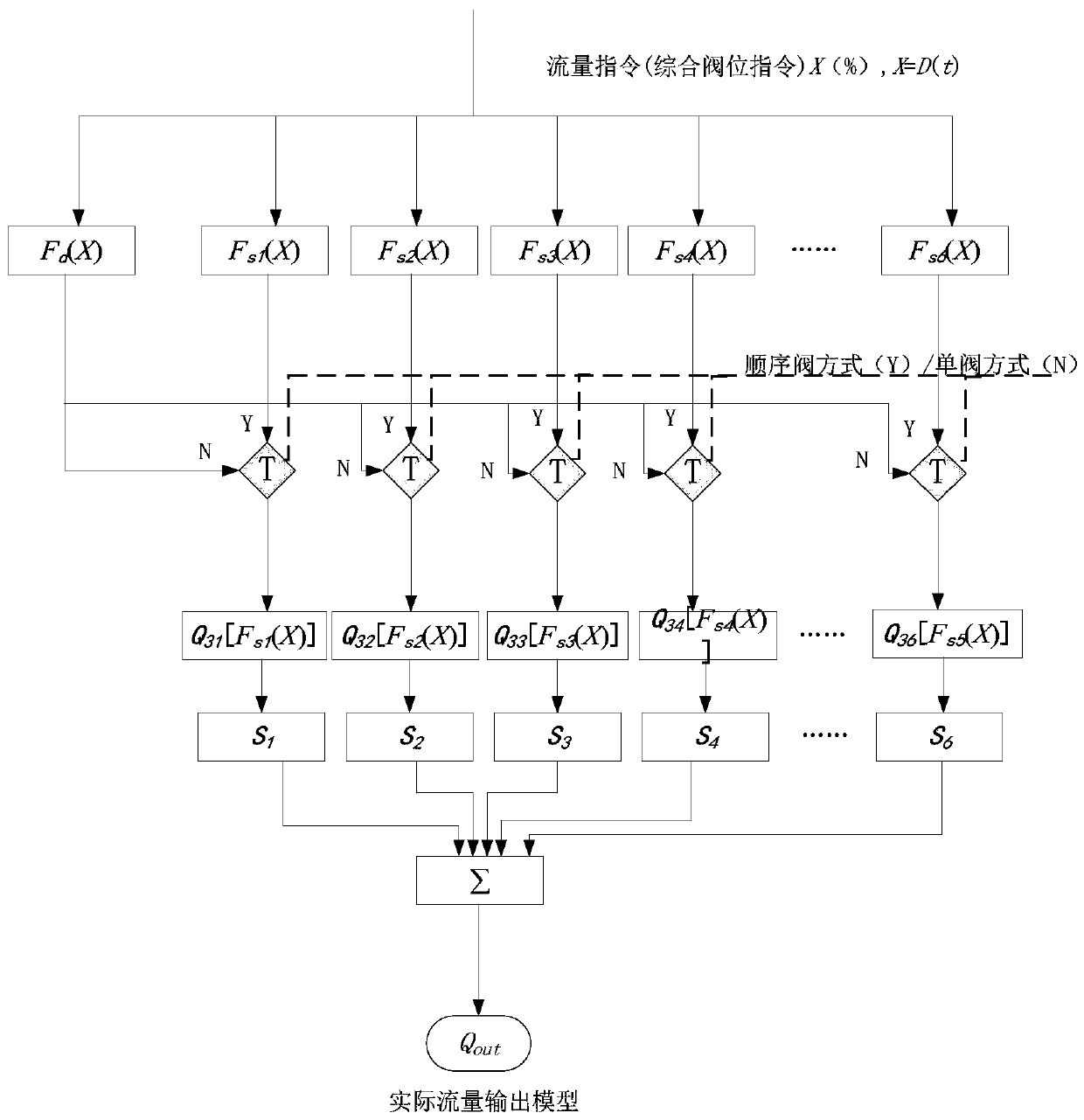

[0089] A kind of steam turbine flow characteristic optimization method based on full-stroke modeling of the present invention comprises the following steps:

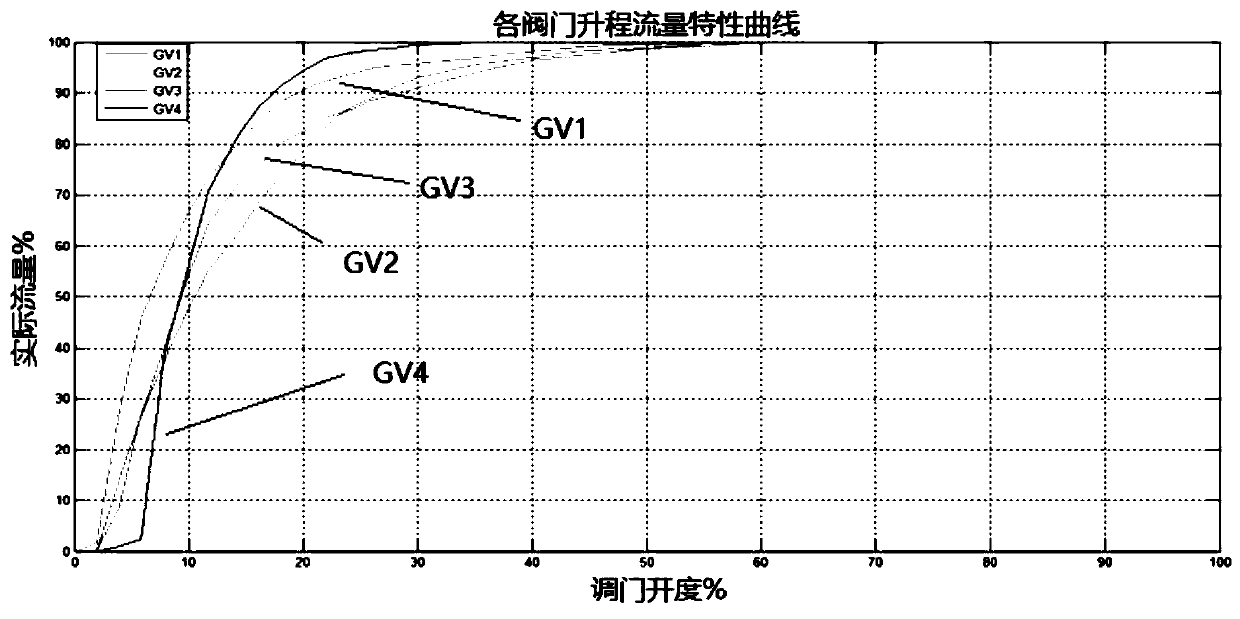

[0090] Step 1: Propose an improved steam turbine high-profile valve flow characteristic test to obtain the total flow command D(t), the main steam pressure P T (t), regulating stage pressure P 1 (t), each door adjustment instruction D i (t), where D(t) represents the total flow command at time t, and D(t)∈[0,100], D i (t) represents the opening command of the i-th high-profile door at time t, D i (t) ∈ [0, 100], see Section 1 for details of the test;

[0091]Step 2: Use filtering technology, clustering algorithm, flow calculation, data per unit and other methods to process data, see Section 2 for details;

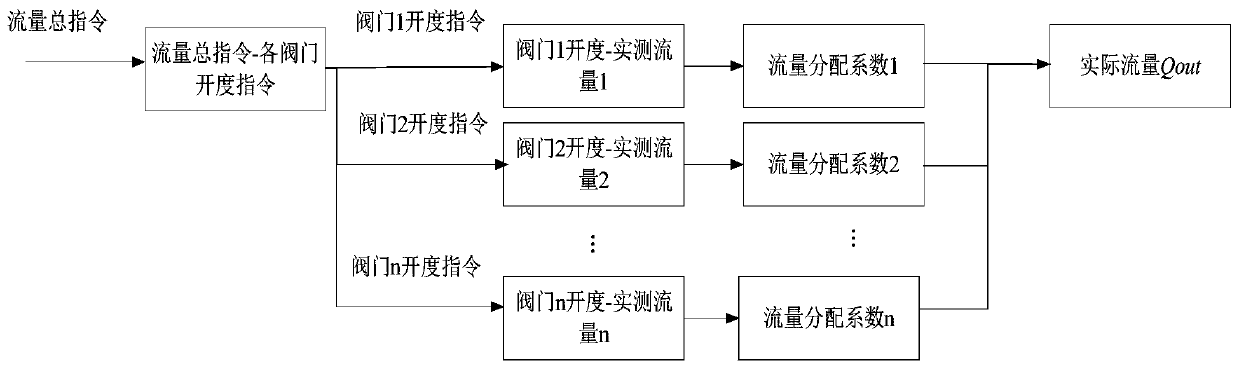

[0092] Step 3: Propose a calculation method of actual flow rate, and calculate the flow distribution coefficient of the control valve in combination with the test, and establish the mathematical modeling of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com