Marine simulator system with upper layer and lower layer

A simulator and marine technology, applied in the field of simulation, can solve problems such as turbulence changes, and achieve the effect of reducing safety risks, improving authenticity, adaptability and anti-risk capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

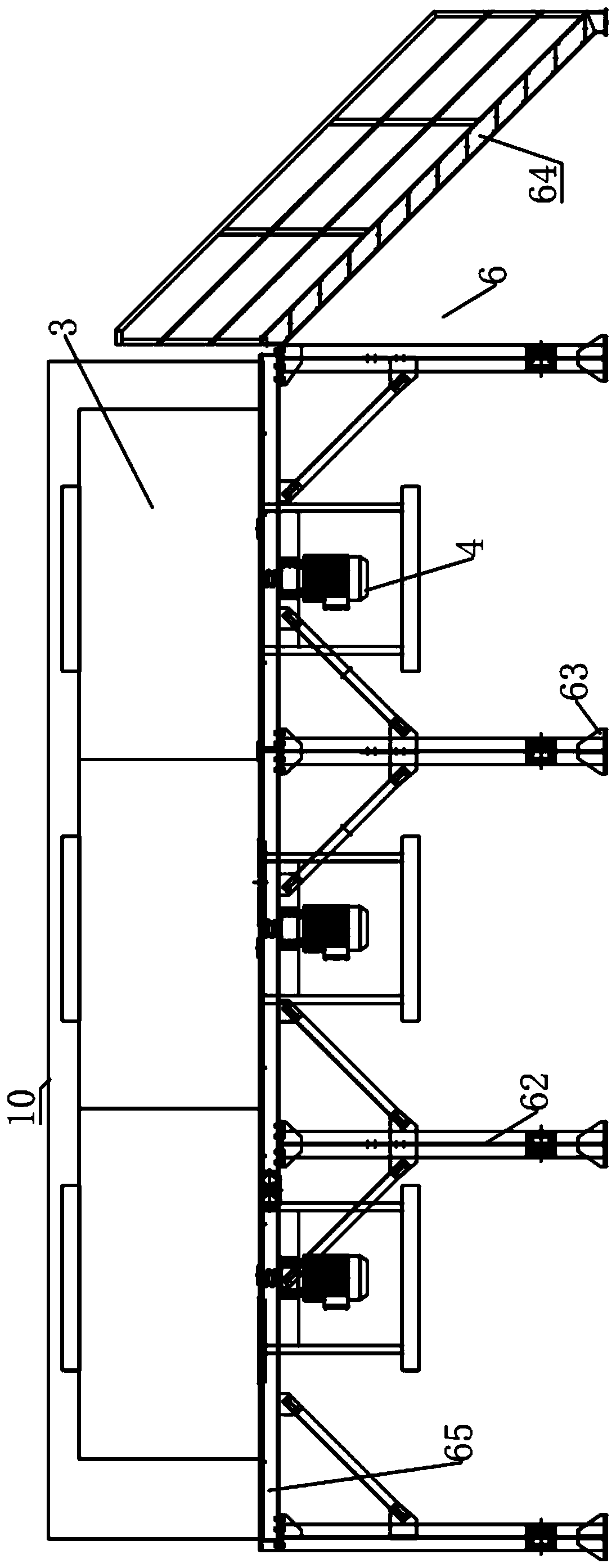

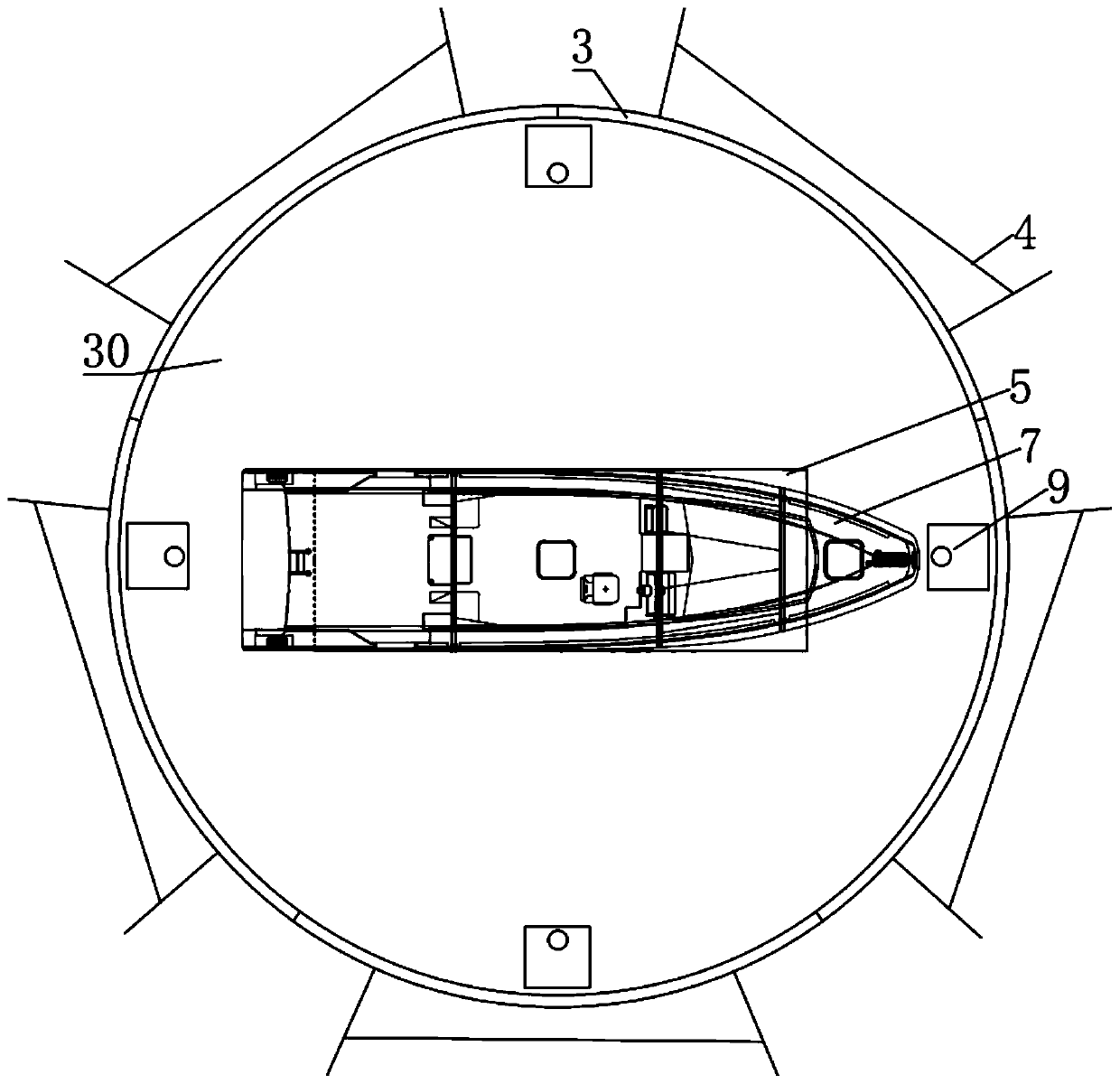

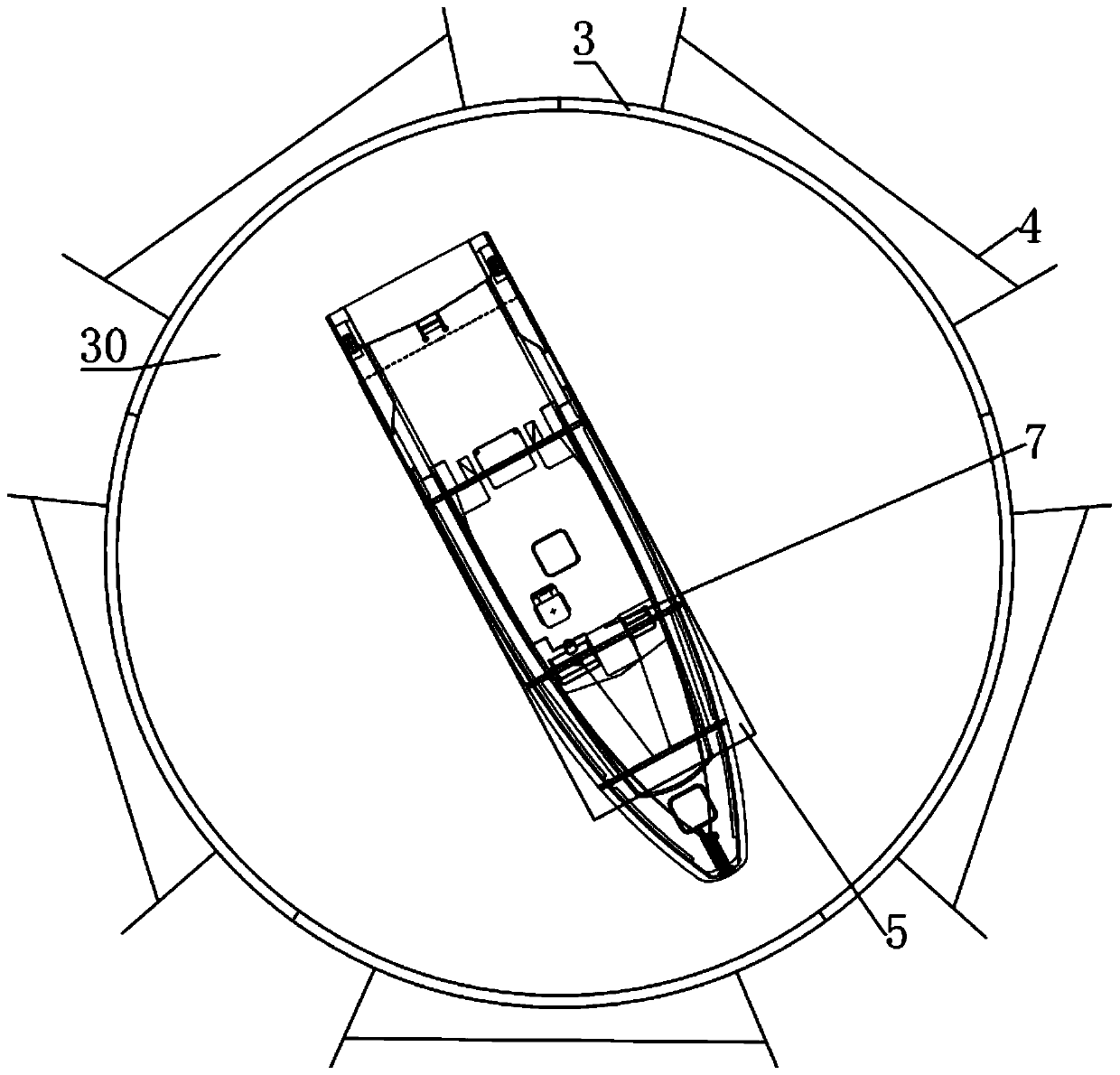

[0034] Such as Figure 1-4 The upper and lower double-deck marine simulator system shown includes a lower six-degree-of-freedom platform 1, an upper six-degree-of-freedom platform 2, a set of arc-shaped displays 3, a set of arc-shaped display support frames 4, a circular rotating platform 5, and an overall Support frame 6, ship body 7, top projection plate 8, a set of top projectors 9, an outer casing 10, a set of bottom projectors 20 and a bottom projection plate 30, the outer casing 10 is covered on the overall support frame 6, The lower six-degree-of-freedom platform 1, the upper six-degree-of-freedom platform 2, a set of arc displays 3, a set of arc display support frames 4, a circular rotating platform 5, a ship body 7, a top projection plate 8, and a set of top The projector 9, a group of bottom projectors 20 and the bottom projection board 30 are all located in the space covered by the outer casing 10, and the set of curved display support frames 4, a group of top proje...

Embodiment 2

[0036] Such as Figure 7 , 8 The circular rotary table 5 shown includes a lower base 51, a rotary drive motor 52, a driving wheel 53, a slewing bearing 54, a circular adapter plate 55 and a rectangular support plate 56, and the lower base 51 is fixedly arranged on the overall support frame 6 Above, the rotary drive motor 52 is arranged on the lower base 51, and the rotary drive motor 52 is connected to the driving wheel 53, the driving wheel 53 is engaged with the ring gear of the slewing bearing 54, and the circular adapter plate 55 is connected to the slewing ring. The support 54 is connected, the rectangular support plate 56 is fixedly connected with the circular adapter plate 55 , and the ship body 7 is fixedly arranged on the rectangular support plate 56 .

Embodiment 3

[0038] Such as Figure 9 , 10 Shown arc display support frame 4 comprises vertical drive motor 41, screw rod one 42, screw rod one support base 43, screw rod two support base 44, slide block one 45, slide block two 46, display screen support plate 47, display screen Support frame 48 and vertical support frame 49, described vertical support frame 49 is fixedly arranged on the overall support frame 6, and described vertical drive motor 41, screw rod one support seat 43 and screw rod two support seat 44 are all fixedly arranged on vertical On the straight support frame 49, the screw rod one 42 is arranged between the screw rod one support base 43 and the screw rod two support base 44, and the screw rod one 42 is connected with the rotating shaft of the vertical drive motor 41, and the slide block one 45 and the slide block Two 46 are all threadedly connected with screw rod one 42, and described display screen support plate 47 is fixedly connected with slide block one 45 and slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com