PVC communication optical fiber cable protection sleeve convenient to sleeve

A cable protection sleeve, communication optical fiber technology, applied in the cable installation in the ground conduit, the cable installation in the underground pipeline, the cable installation, etc. Anti-slippage, high stability and high oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

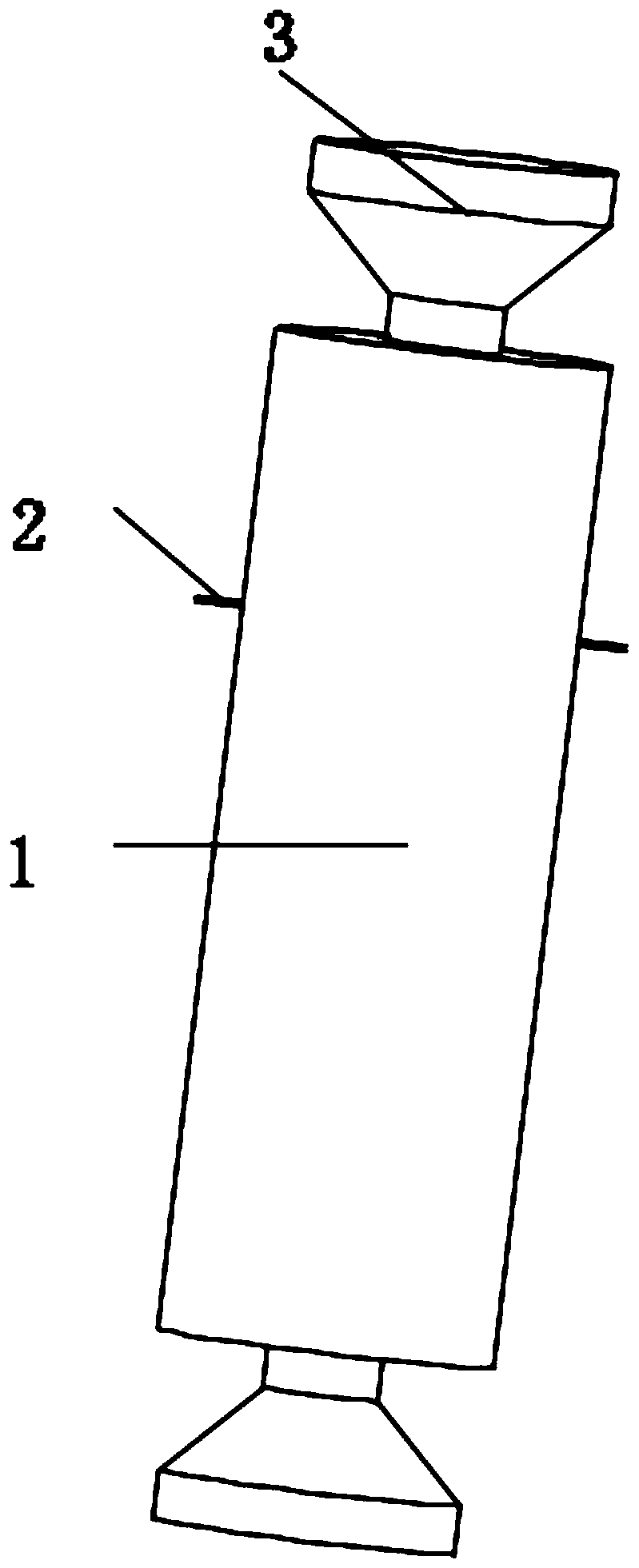

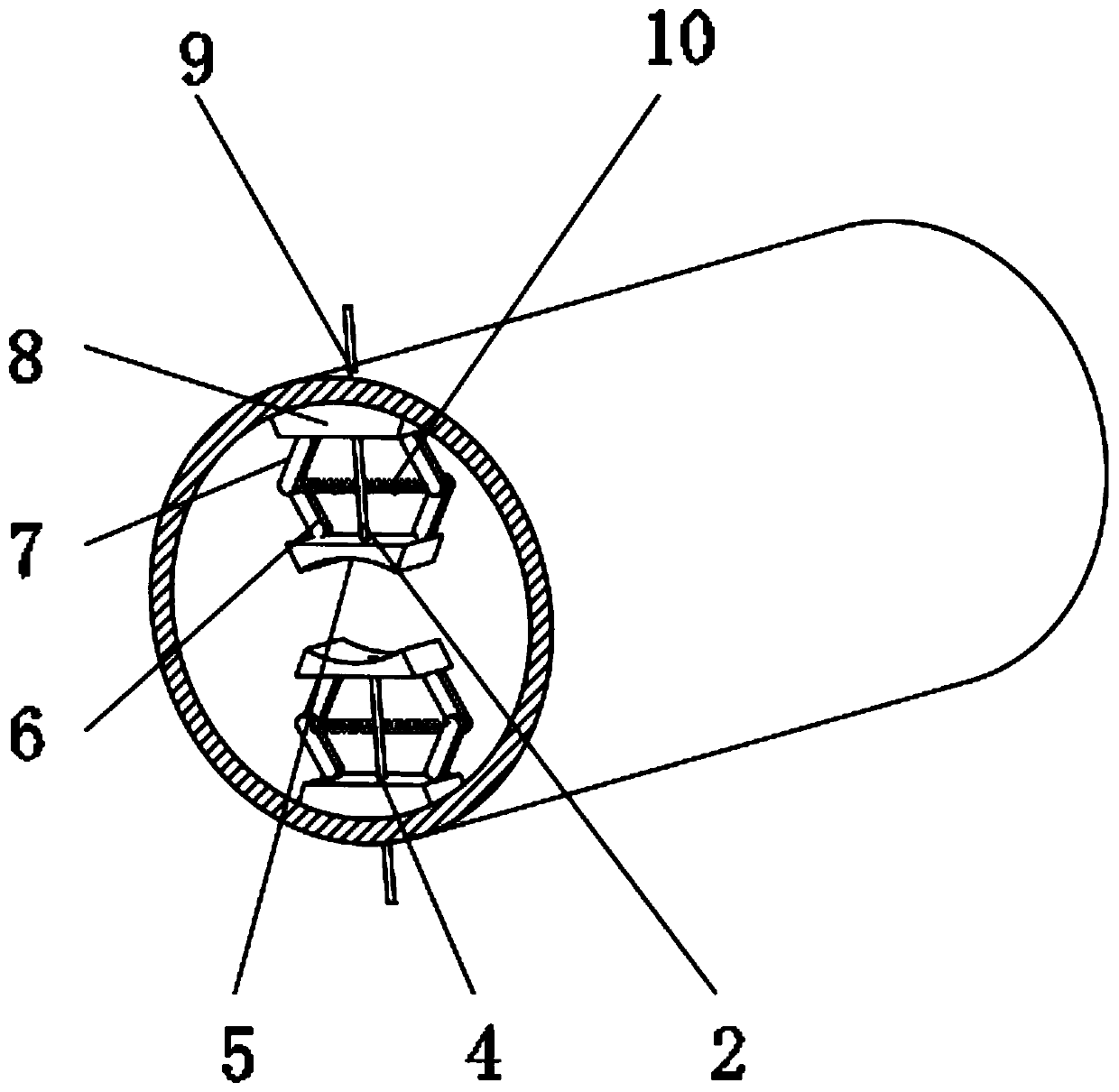

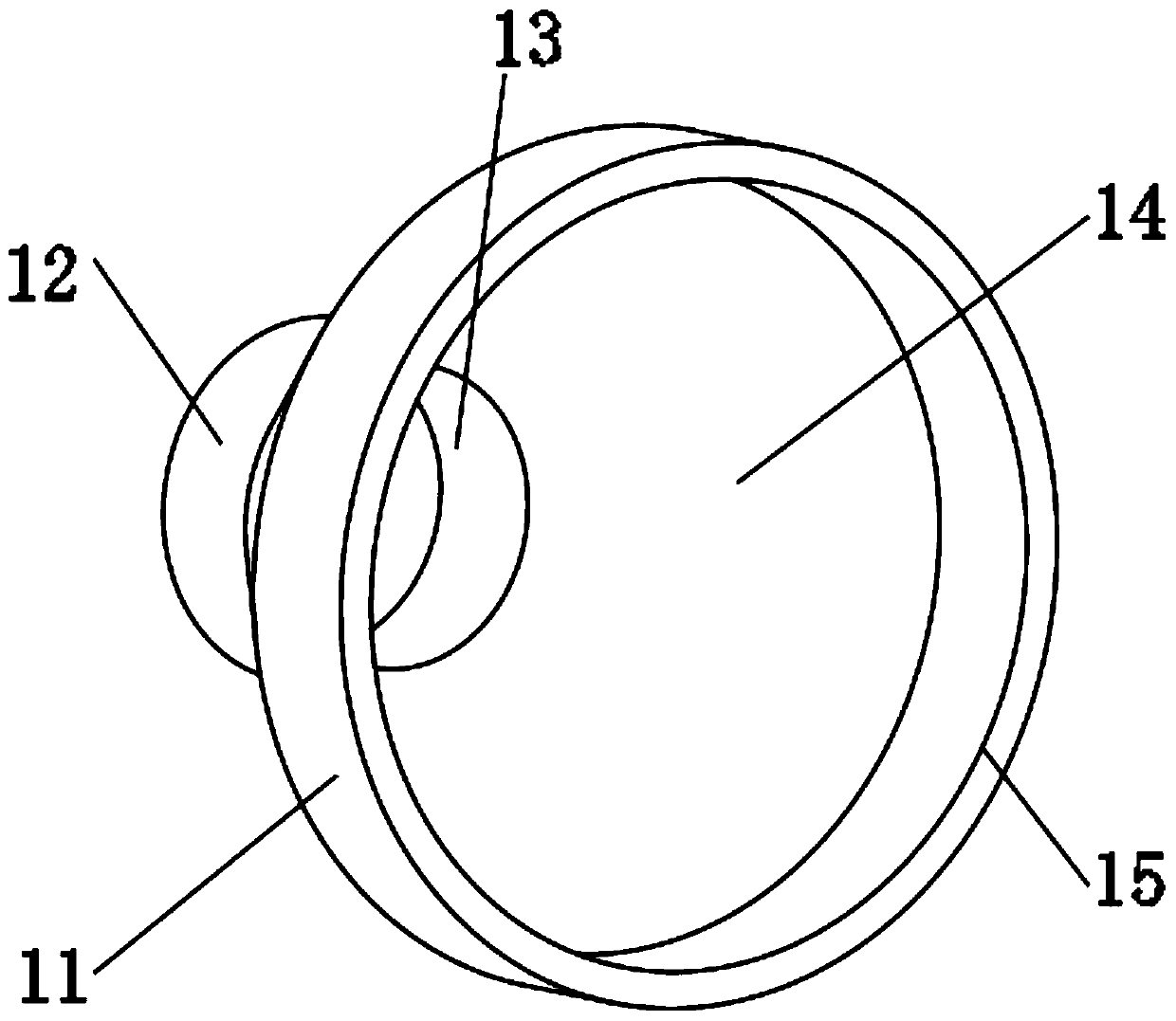

[0029] A protective sleeve for PVC communication optical fiber cables that is easy to set, such as figure 1 , 2 As shown, it includes a sleeve main body 1 and a sealing joint 3 used in conjunction with the sleeve main body 1. The two sealing joints 3 are respectively symmetrically matched to the two end faces of the sleeve main body 1, and the sleeve main body 1 is close to the two ends. The inner walls of each end face are provided with a clamping assembly, and the distance between the clamping assembly and the end face of the casing main body 1 is greater than the width of the sealing joint 3; when in use, first put the sealing joint 3 on the cable, and then plug the cable into into the casing main body 1, and slowly tighten the cable so that the sealing joint 3 is completely embedded in the inner wall of the casing main body 1. After reaching the desired position, put another sealing joint 3 on the cable and slide slowly so that Two sealing joints 3 are respectively embedd...

Embodiment 2

[0039] A protective sleeve for PVC communication optical fiber cables that is easy to set, such as figure 1 , 2 As shown, it includes a sleeve main body 1 and a sealing joint 3 used in conjunction with the sleeve main body 1. The two sealing joints 3 are respectively symmetrically matched to the two end faces of the sleeve main body 1, and the sleeve main body 1 is close to the two ends. The inner walls of each end face are provided with a clamping assembly, and the distance between the clamping assembly and the end face of the casing main body 1 is greater than the width of the sealing joint 3; when in use, first put the sealing joint 3 on the cable, and then plug the cable into into the casing main body 1, and slowly tighten the cable so that the sealing joint 3 is completely embedded in the inner wall of the casing main body 1. After reaching the desired position, put another sealing joint 3 on the cable and slide slowly so that Two sealing joints 3 are respectively embedd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com