Universal motor

A relay and electrical connection technology, applied in the field of chip servo motor systems, can solve the problems of increasing accumulated errors, increasing system complexity, reducing system reliability and sensitivity, and achieving the effect of simplifying the structure and simplifying the mechanical mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

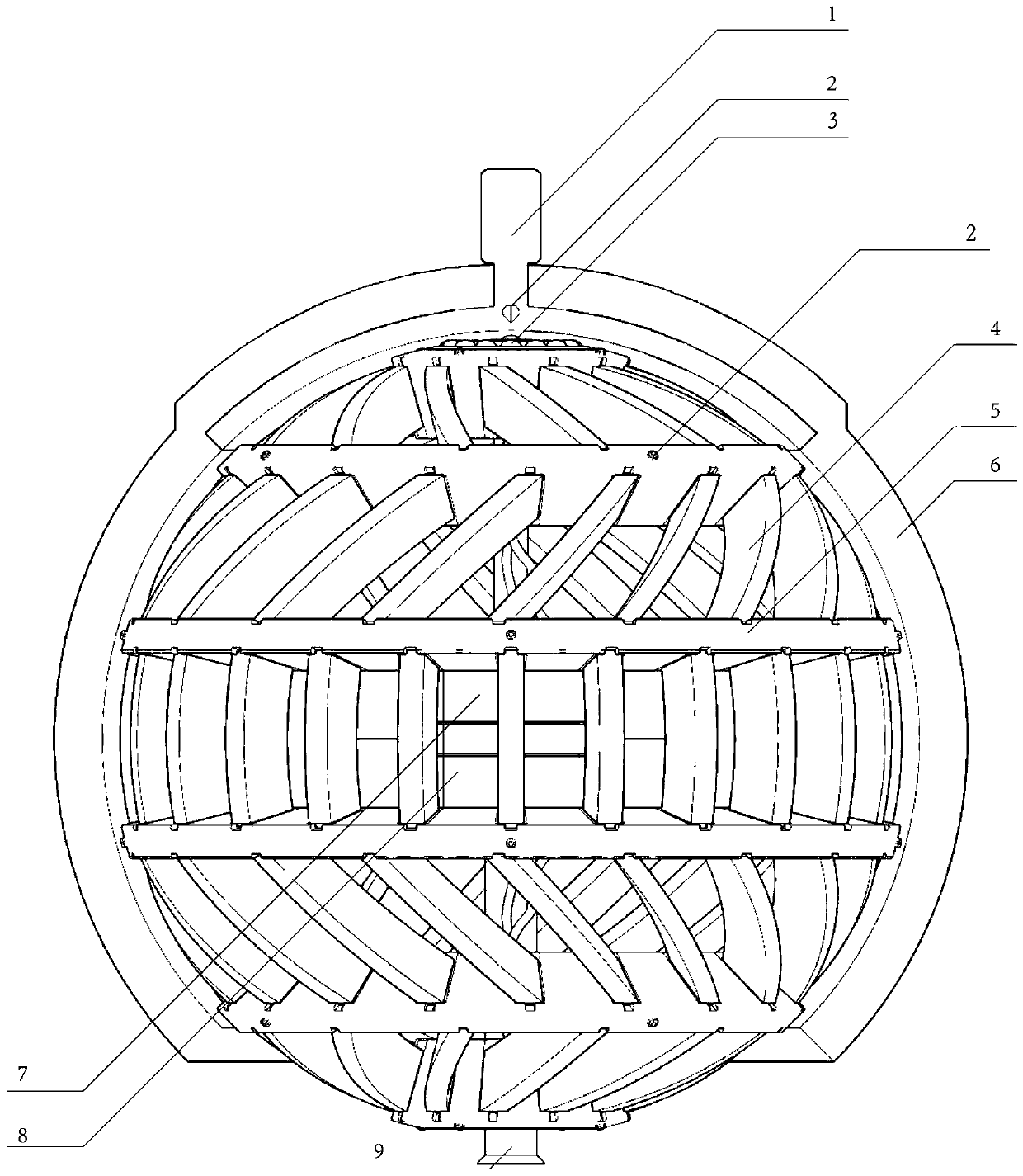

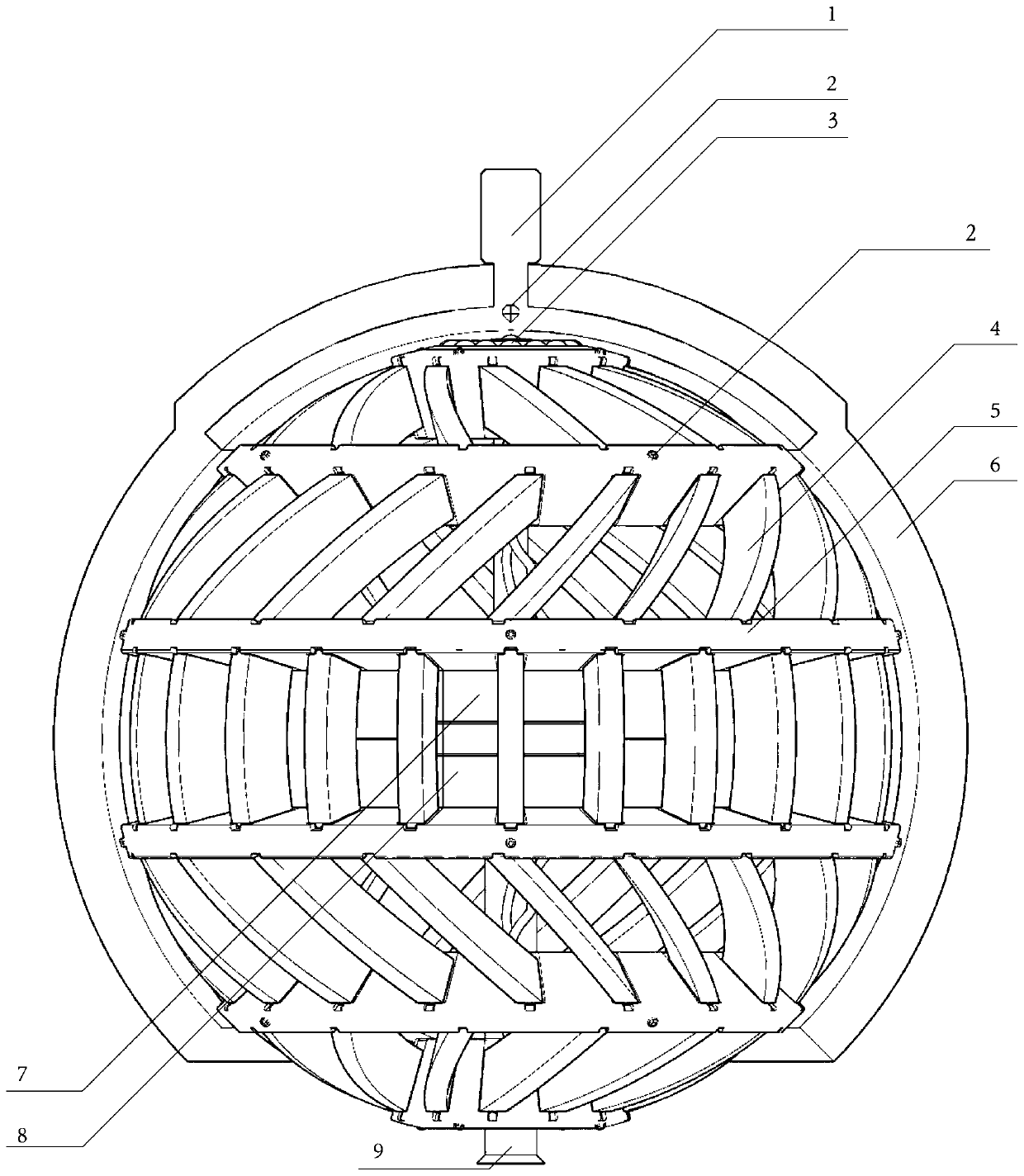

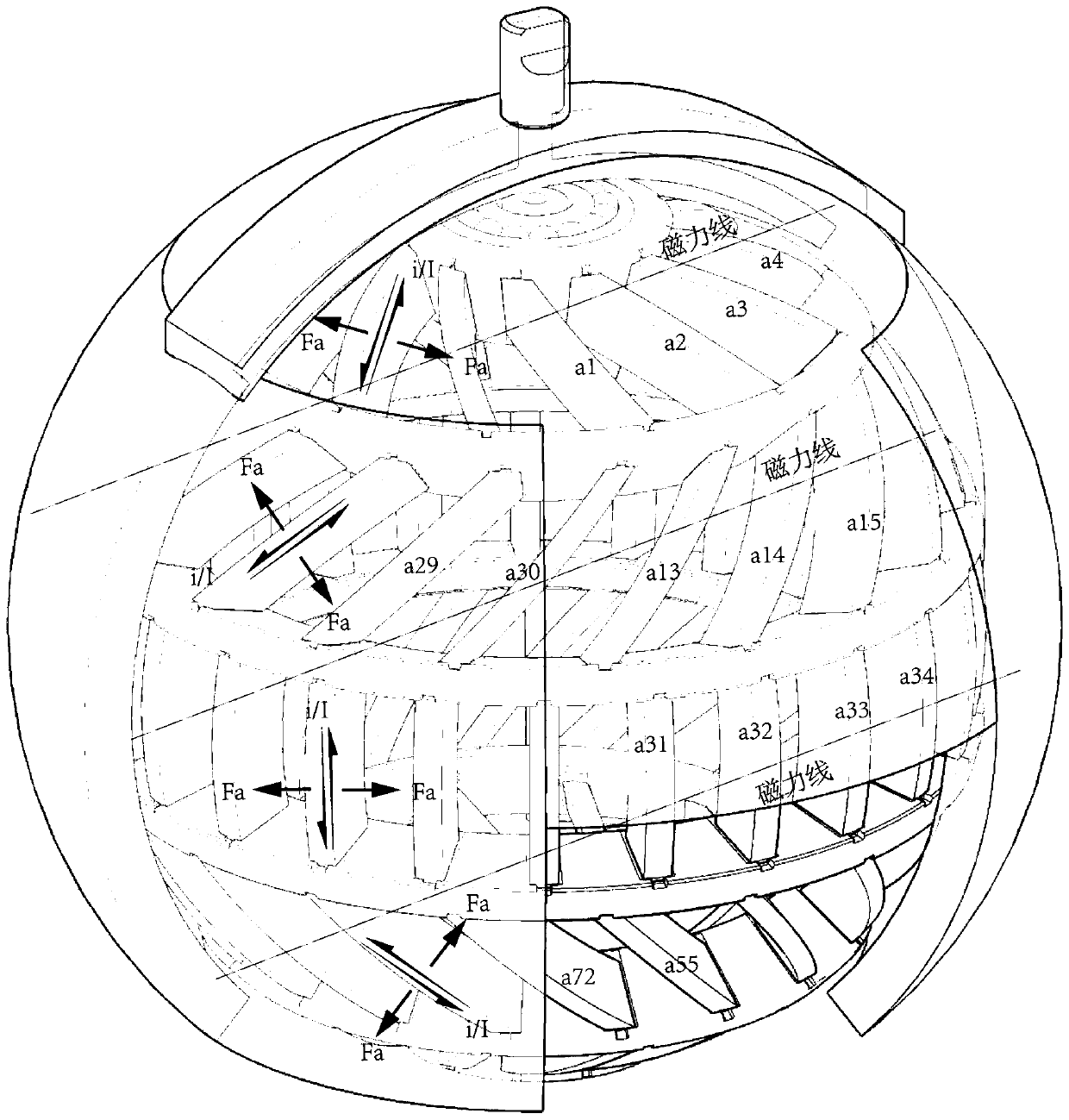

[0033] see figure 1 , figure 2 , image 3 , the present invention provides a universal motor, comprising a permanent magnet rotor 6, a stator energized wire 4 and an annular base 5, a spherical cap bearing 3, a Hall sensor 2, a chip servo system 8 and a relay 7, the chip servo system 8 Fixed inside or outside the stator base 5, the permanent magnet rotor 6 is located above the stator base 5, and the spherical crown bearing 3 is used for gravity support between the permanent magnet rotor 6 and the stator base 5, and the spherical crown bearing 3 and the stator base 5 are supported by gravity. The stator base 5 is fixedly connected; the top of the permanent magnet rotor 6 is rigidly connected to the rotor shaft 1, and the rotor shaft 1 and the permanent magnet rotor 6 are integrally structured, and multiple groups of spherical spiral conducting wires 4 are arranged on the stator base 5; the chip Servo system 8 comprises IC chip, and the relay 7 that is electrically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com