A high-efficiency steaming device for food processing

A food processing and steaming technology, applied in applications, kitchen utensils, household utensils, etc., can solve the problems of low utilization rate of steaming heat, excessive steaming, insufficient steaming, etc., to improve utilization rate, improve efficiency, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

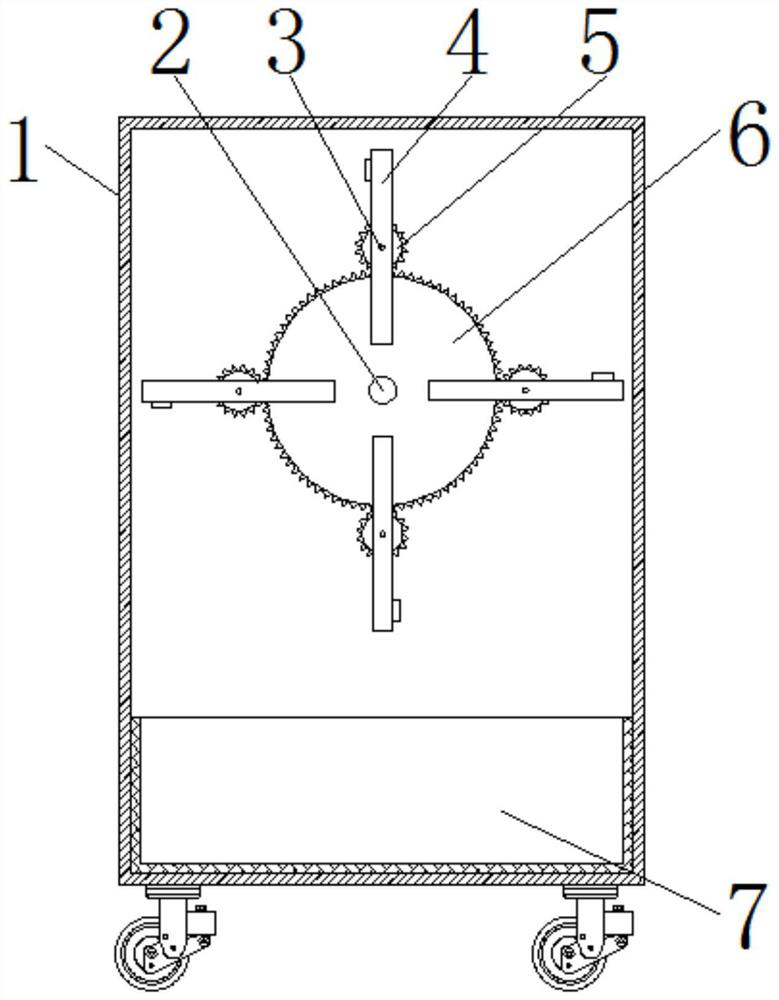

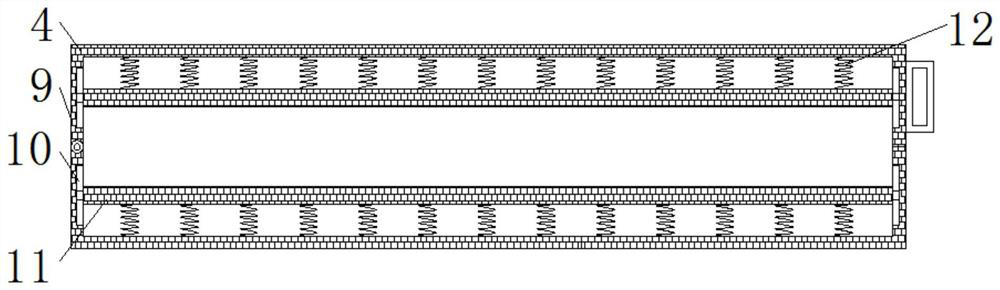

[0029] Such as Figure 1-6 As shown, the embodiment of the present invention provides a high-efficiency steaming device for food processing, including a box body 1, a servo motor 8, and a steam box 7. The inside of the box body 1 is provided with a fixing member 6 and a driving disk 14, and the fixing member 6 is located in front of the driving disk 14, the driving end of the servo motor 8 extends through the side wall of the box body 1 to its interior and is fixedly connected to the center of the driving disk 14, and the fixing member 6 is fixedly connected to the center of the side wall away from the driving disk 14 There is a connecting shaft 2, the end of the connecting shaft 2 away from the driving disk 14 is fixedly connected to the inner wall of the box body 1, and the outer surface of the driving disk 14 is fixedly connected with a plurality of fixed rods 13, and the plurality of fixed rods 13 are distributed in an annular array, and many One end side wall of each fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com