Petroleum extraction device for petroleum residues

An extraction device, oil technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of poor separation effect and waste of residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

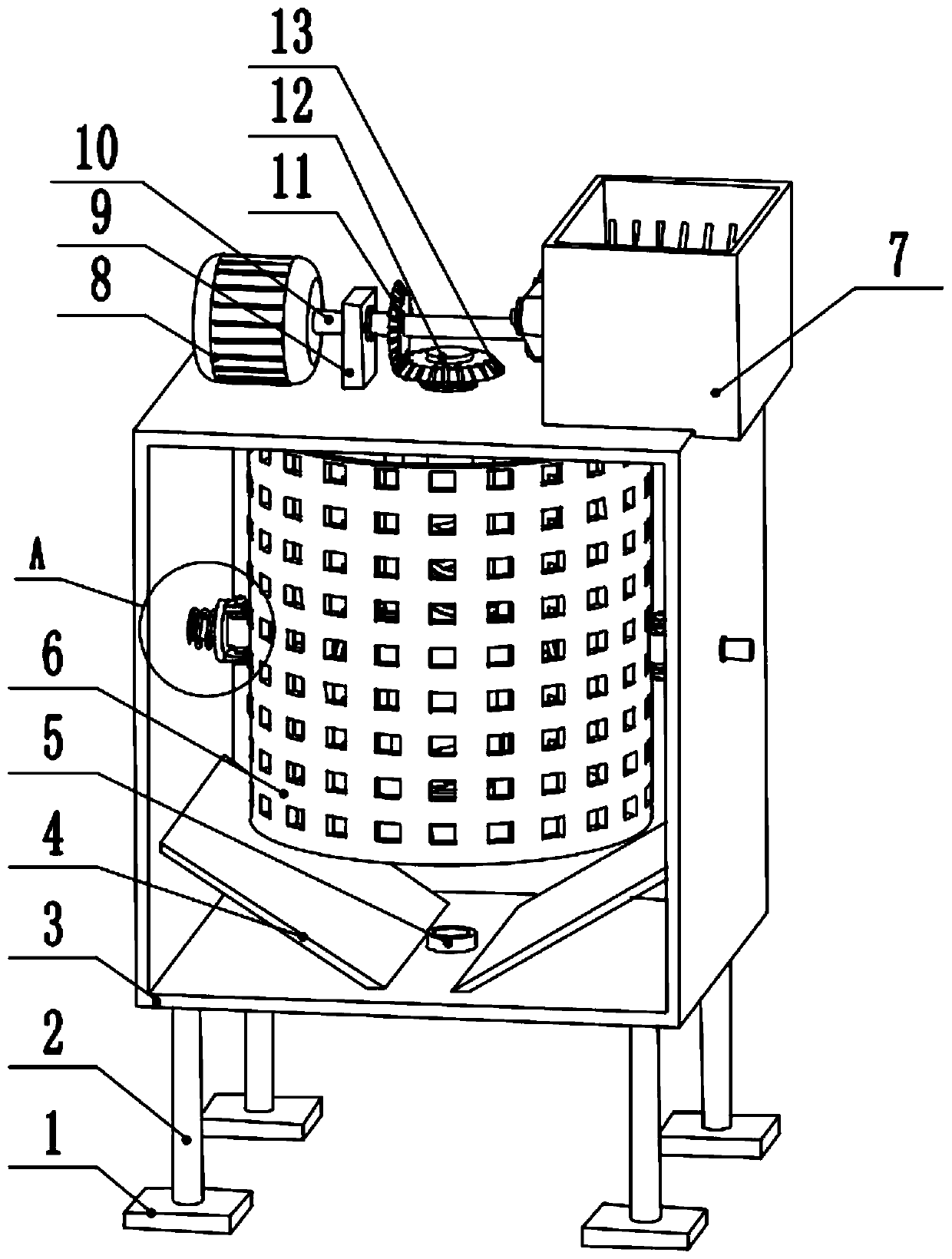

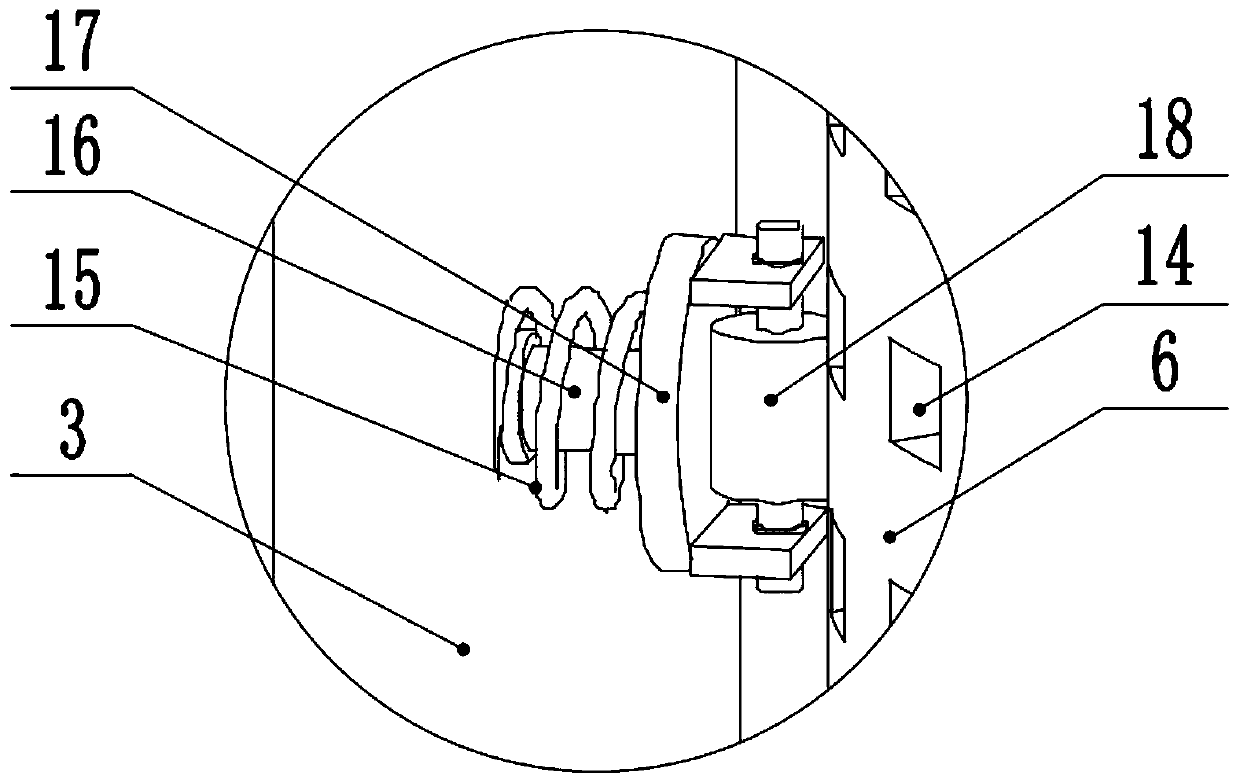

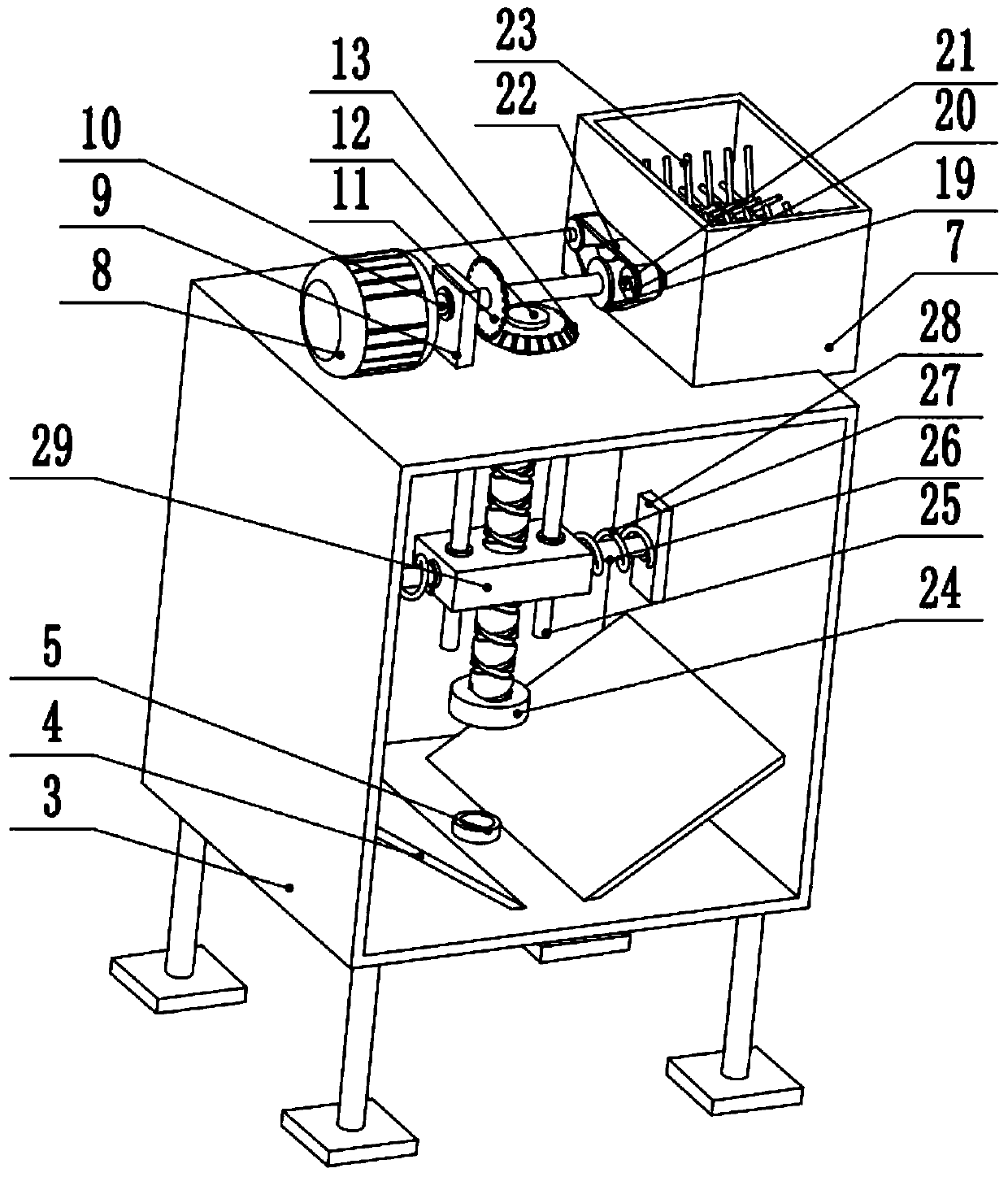

[0027] see Figure 1-4 , a petroleum extraction device for petroleum residues, comprising a separation box 3, the middle part of the lower surface of the separation box 3 is provided with an oil discharge port 5, the left side of the upper surface of the separation box 3 is provided with a drive motor 8, and the output shaft of the drive motor 8 is fixed Connect the left end of the rotating shaft 10, the middle part of the rotating shaft 10 is provided with a first bevel gear 11, the first bevel gear 11 meshes with the second bevel gear 13, the second bevel gear 13 is fixedly connected to the upper end of the rotating rod 12, and the upper part of the rotating rod 12 rotates Connect the upper part of the crushing box 7, the middle part of the rotating rod 12 is threaded to connect the lifting block 29, and the bottom of the rotating rod 12 is provided with a double helical chute, so when the rotating rod 12 rotates, the lifting block 29 moves up and down along the double helica...

Embodiment 2

[0030] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, except that: the lower part of the left and right side walls of the separation box 3 is provided with a deflector 4 . Due to the high viscosity of oil, in order to avoid oil deposition inside the device, two inclined deflectors 4 are set at the bottom of the device, through which the oil can gather in the middle of the bottom of the device and pass through the oil outlet 5 discharge.

[0031]In the implementation process of the present invention, the drive motor 8 is started, and the output shaft of the drive motor 8 drives the rotating shaft 10 to rotate, and the rotating shaft 10 drives the two crushing shafts 20 to rotate through the first pulley 19, the belt 22 and the second pulley 21, and the crushing shaft 20 drives the crushing rod 23 to rotate at a high speed. At this time, the petroleum residue that needs to be further purified is put into the crushing box 7. The petroleu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com