A kind of high-capacity magnesium-based composite hydrogen storage material and its preparation method

A hydrogen storage material and high-capacity technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as restricting the rapid development of hydrogen energy, and achieve good hydrogen absorption and desorption kinetic performance, high degree of hydrogenation, and material size. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

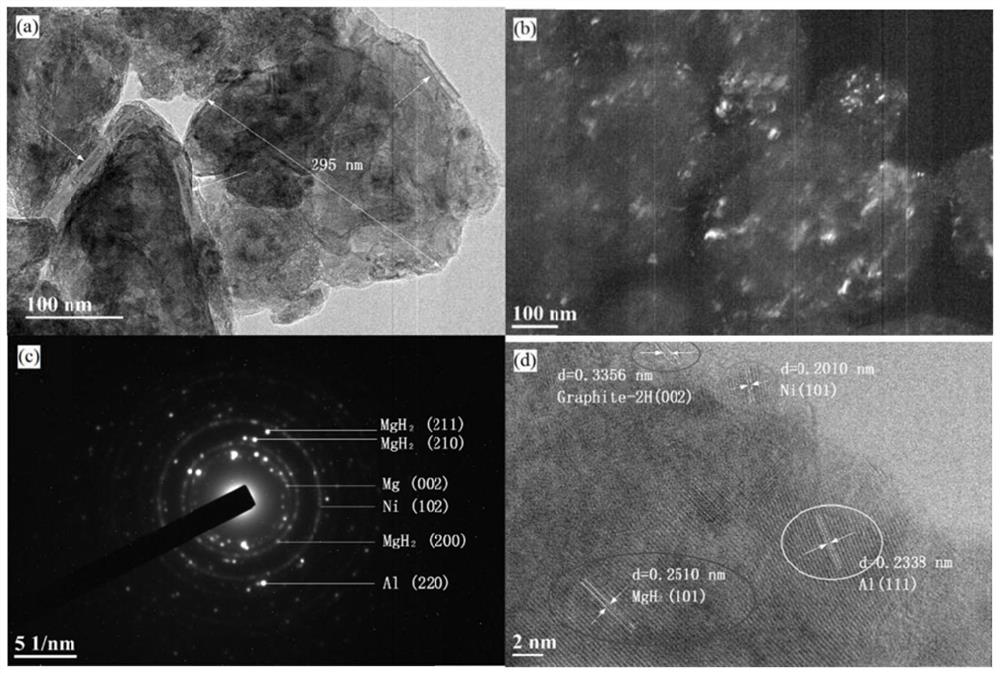

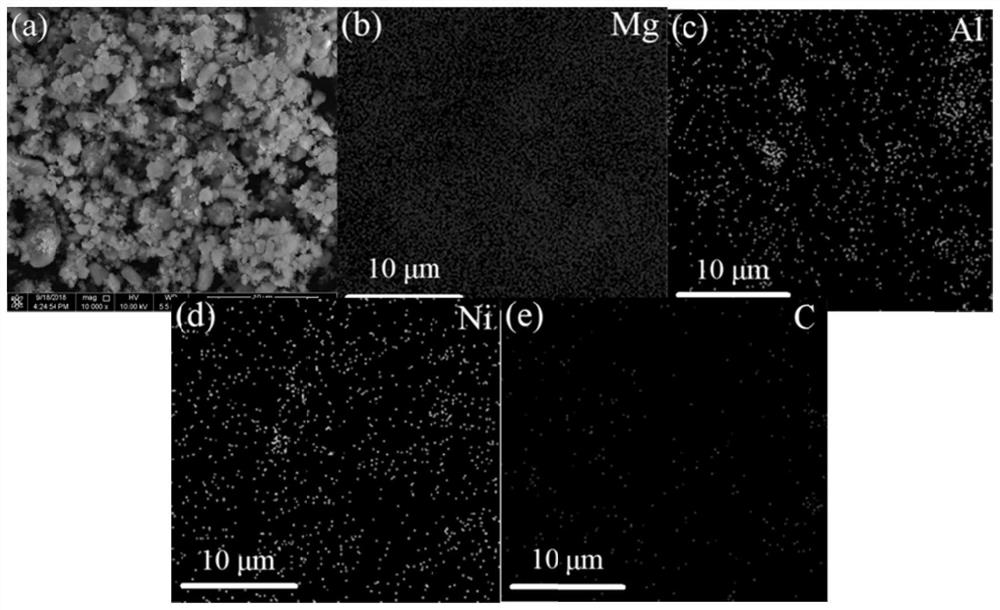

[0041] The high-capacity Mg of the present invention x Al 100-x - A method for preparing a y(z wt%Ni@Gn) composite hydrogen storage material, comprising the steps of:

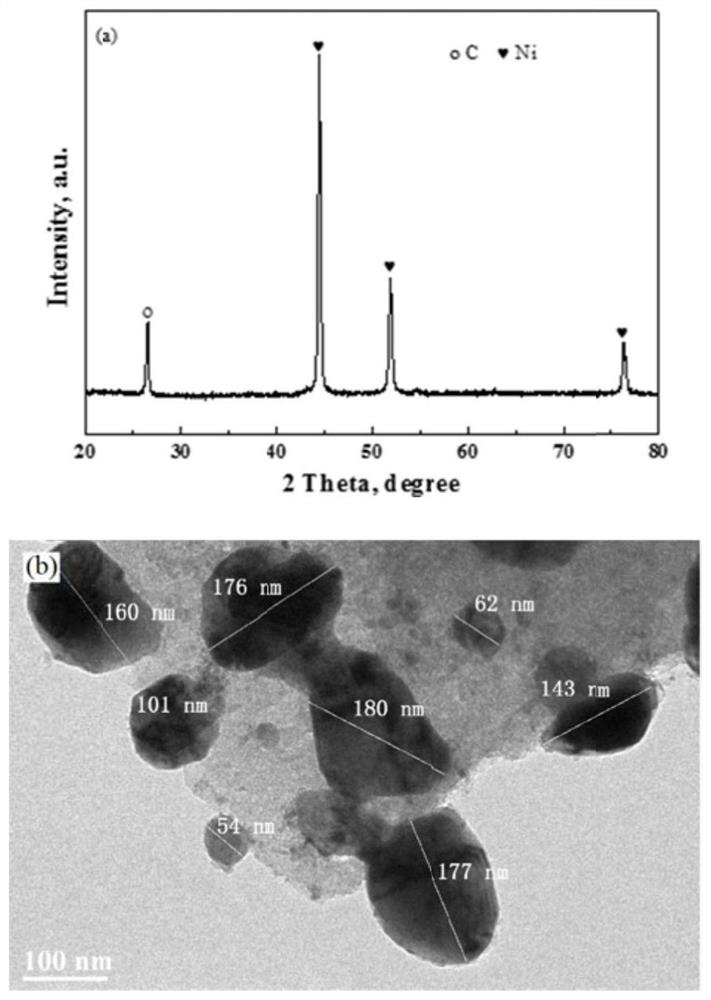

[0042] (1) Mix 30ml of concentrated nitric acid with 1g of graphene nanosheets, heat and stir in an oil bath at 120°C for 6h, then dilute the obtained mixed solution to neutrality and filter, dry in an oven, and set aside;

[0043] (2) with the graphene material after the above-mentioned treatment and nickel nitrate hexahydrate, control the mass ratio of nickel in graphene and nickel nitrate hexahydrate to be 20:80 (that is, the content of Ni accounts for the proportion of the graphene material and nickel nitrate hexahydrate 80wt% of the total amount), added into acetone for ultrasonic dissolution for 1h, then placed in an oven at 52°C for 24h, and set aside;

[0044] (3) The dry product obtained in step (2) is placed in a tube furnace, calcined at 400° C. for 4 h under an argon atmosphere, and then calcined ...

Embodiment 2

[0054] The high-capacity Mg of the present invention x Al 100-x - A method for preparing a y(z wt%Ni@Gn) composite hydrogen storage material, comprising the steps of:

[0055] (1) Mix 30ml of concentrated nitric acid with 1g of graphene nanosheets, heat and stir in an oil bath at 120°C for 6h, then dilute the obtained mixed solution to neutrality and filter, dry in an oven, and set aside;

[0056] (2) With the above-mentioned treated graphene material and nickel nitrate hexahydrate, the mass ratio of nickel in graphene and nickel nitrate hexahydrate is controlled to be 20:80, add in acetone and carry out ultrasonic dissolution for 1h, then place it in an oven at 52 ℃ to dry for 24h, set aside;

[0057] (3) The dry product obtained in step (2) is placed in a tube furnace, calcined at 400° C. for 4 h under an argon atmosphere, and then calcined at 450° C. for 4 h under a hydrogen atmosphere to obtain a product that is a graphene-supported nickel catalyst. spare;

[0058] (4)...

Embodiment 3

[0062] The high-capacity Mg of the present invention x Al 100-x - A method for preparing a y(z wt%Ni@Gn) composite hydrogen storage material, comprising the steps of:

[0063] (1) Mix 30ml of concentrated nitric acid with 1g of graphene nanosheets, heat and stir in an oil bath at 120°C for 6h, then dilute the obtained mixed solution to neutrality and filter, dry in an oven, and set aside;

[0064] (2) With the above-mentioned treated graphene material and nickel nitrate hexahydrate, the mass ratio of nickel in graphene and nickel nitrate hexahydrate is controlled to be 20:80, add in acetone and carry out ultrasonic dissolution for 1h, then place it in an oven at 52 ℃ to dry for 24h, set aside;

[0065] (3) The dry product obtained in step (2) is placed in a tube furnace, calcined at 400° C. for 4 h under an argon atmosphere, and then calcined at 450° C. for 4 h under a hydrogen atmosphere to obtain a product that is a graphene-supported nickel catalyst. spare;

[0066] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com