A concrete pouring cage support mechanism for building construction

A technology for building construction and supporting mechanisms, applied in manufacturing tools, ceramic molding machines, supply devices, etc., can solve problems such as stress concentration of concrete soil columns, a large number of trachoma, and impact on bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

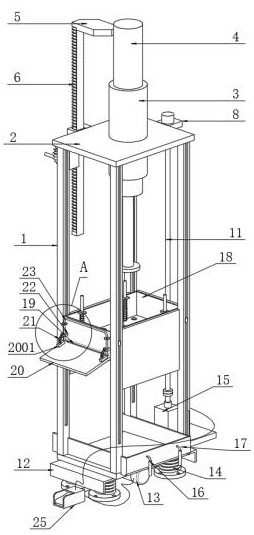

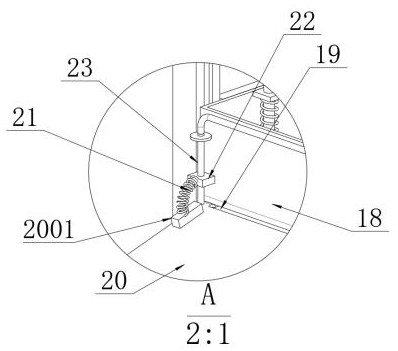

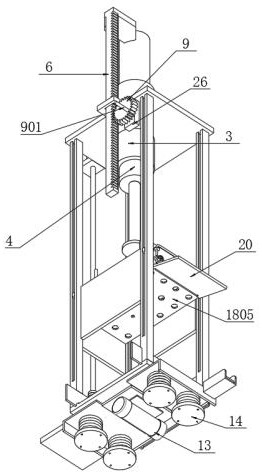

[0043] as attached figure 1 to attach Figure 13 Shown:

[0044] The present invention provides the concrete casting type cage support mechanism for building construction, comprising frame 1, electric cylinder 4, push seat 17 and functional seat 18, such as figure 1 , image 3 As shown, the frame 1 is four vertical rectangular tubes, the top and the bottom of the frame 1 are welded with an end plate 2, the bottom surface of the end plate 2 is welded with a bottom plate 12, the bottom plate 12 is an inverted U-shaped structure, and the inverted U-shaped structure of the bottom plate 12 The vibration motor 13 is installed on the U-shaped bottom surface; the bottom surface of the base plate 12 is evenly provided with four spring seats 14, the vibration motor 13 is positioned at the inboard of the spring seat 14, and the outside of the vibration motor 13 is electrically connected with a foot switch 25, the foot switch 25 is electrically connected to the external power supply, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com