Mine wastewater circulating treatment system

A technology for circular treatment of mine wastewater, applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems that cannot meet the needs of mine wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

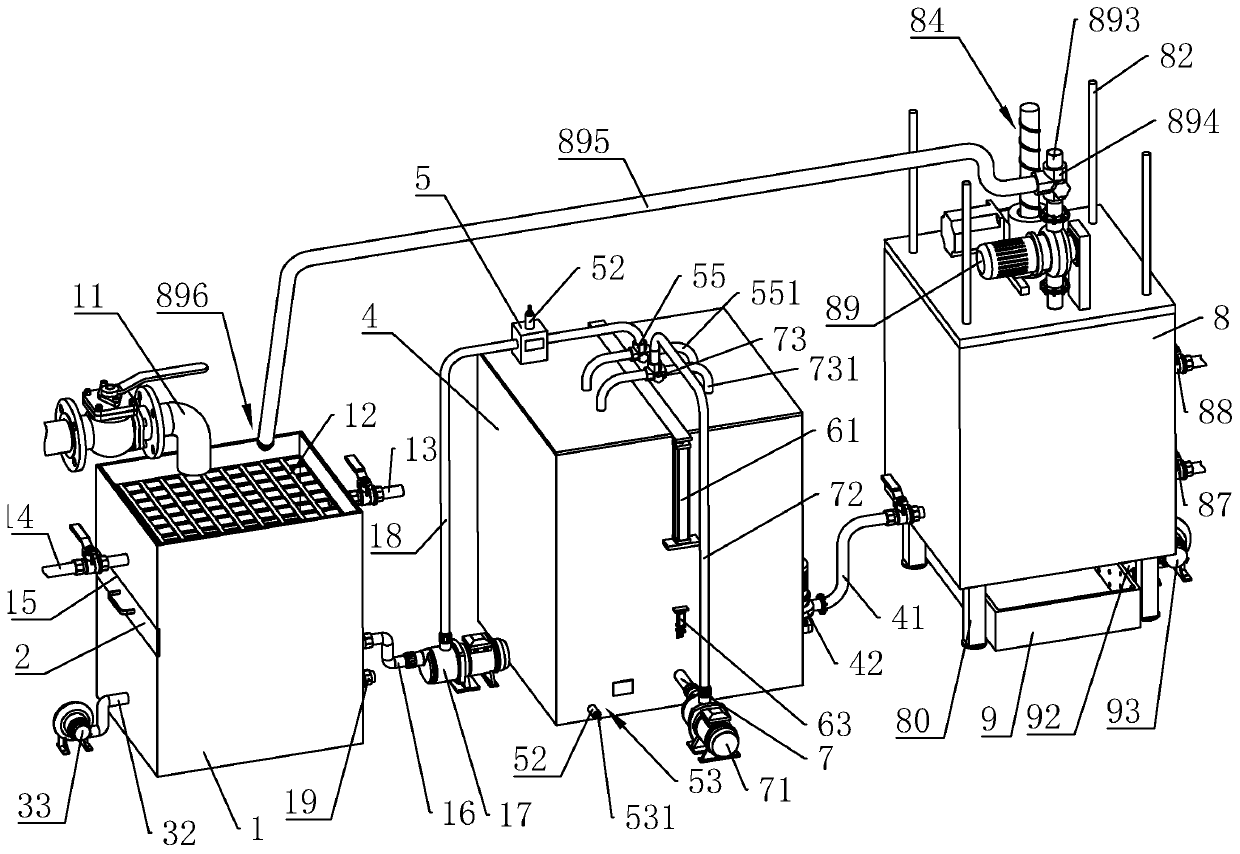

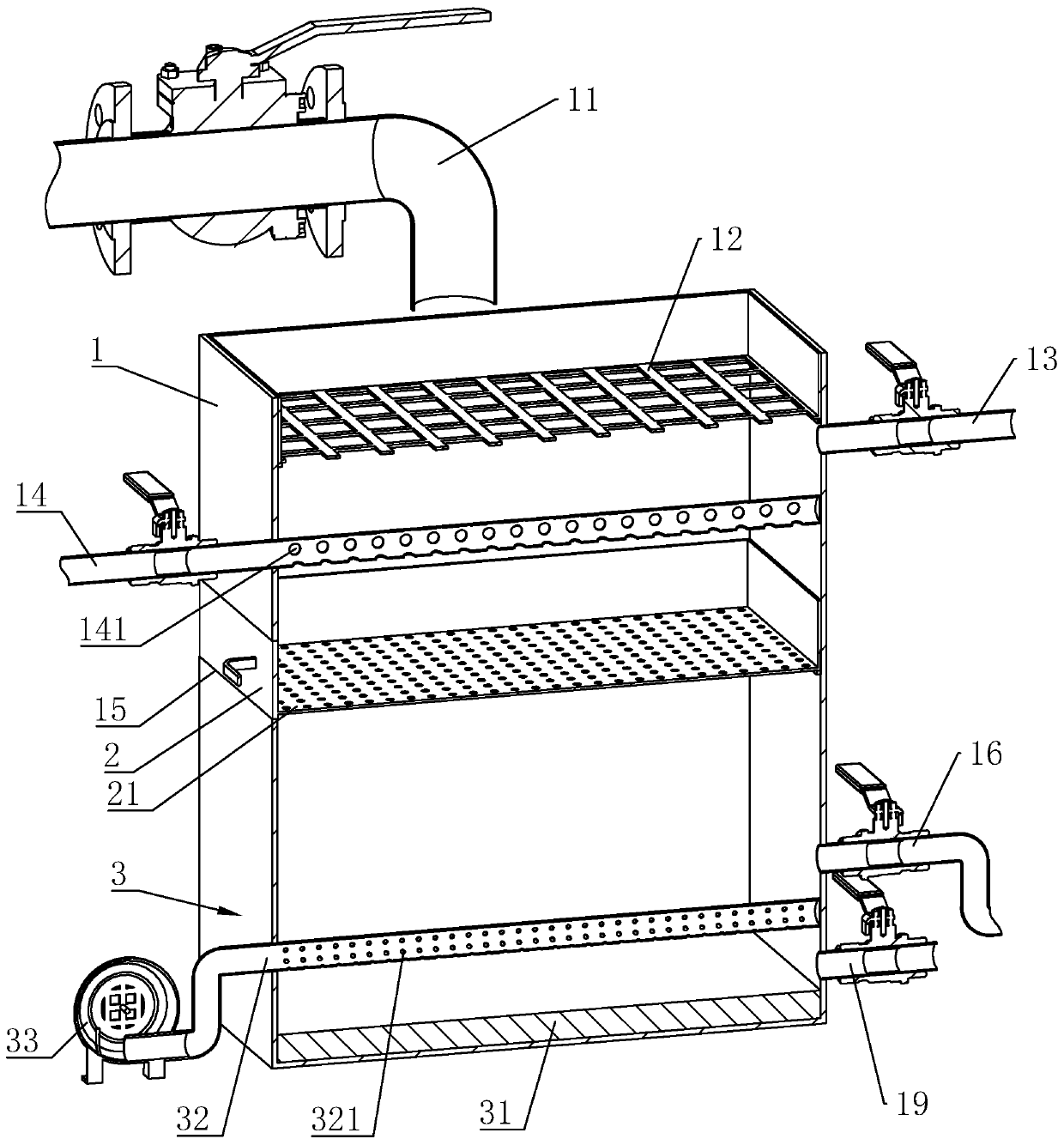

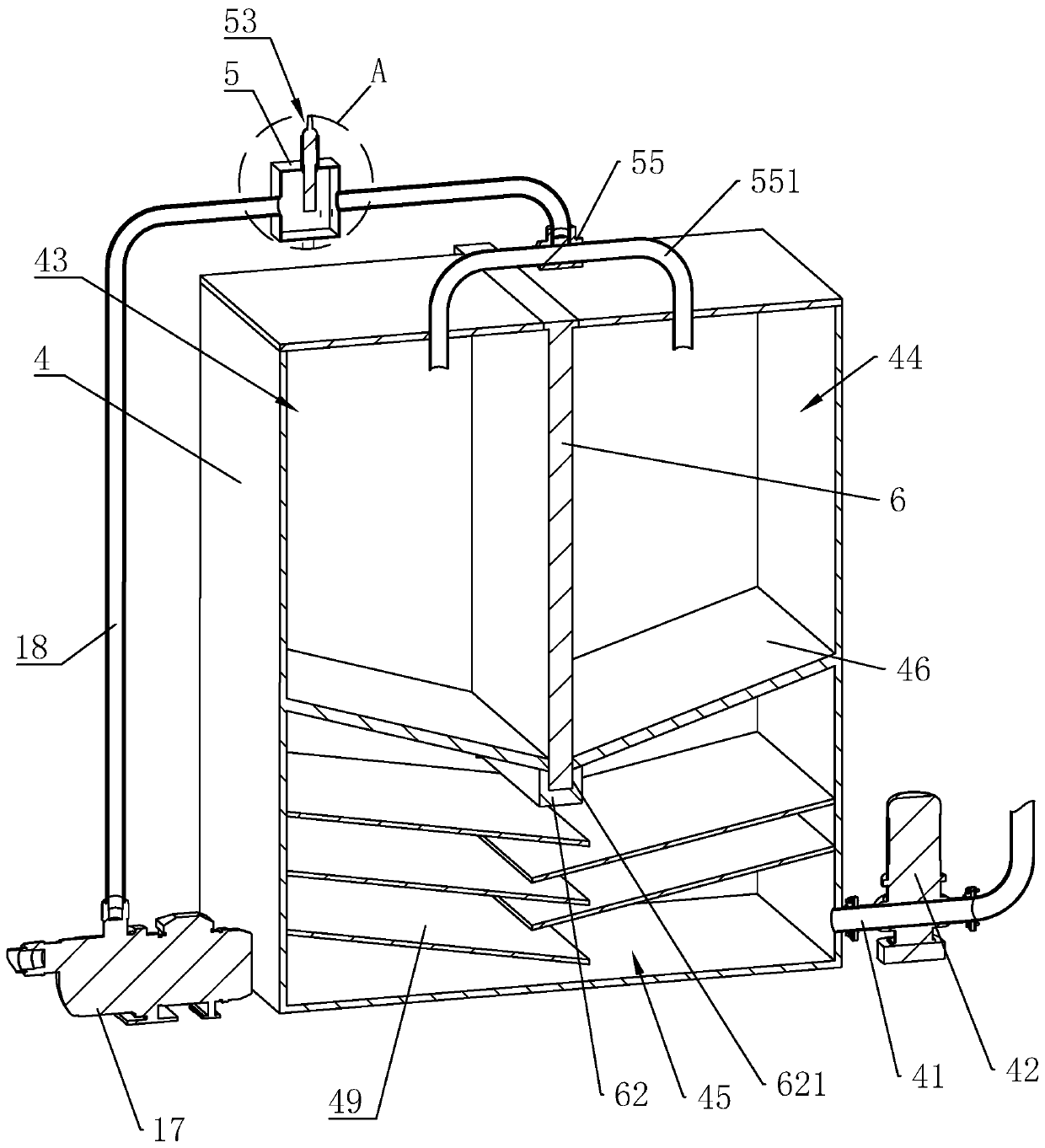

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0044] refer to figure 1 , is a kind of mine waste water circulating treatment system disclosed by the present invention, which successively includes a sedimentation tank 1, an acid-base neutralization tank 4, and a press filter tank 8. Inlet pipe one 11, the side wall of the sedimentation tank 1 towards the acid-base neutralization tank 4 is connected with the water inlet pipe 2 13 for domestic water introduction near the top, and the side wall of the sedimentation tank 1 towards the acid-base neutralization tank 4 is connected with the middle and lower part There is a water outlet pipe 16, and the water outlet pipe 16 is externally connected with a lifting water pump 17, and the lifting water pump 17 is connected to the top surface of the acid-base neutralization tank 4 through the water guide pipe 18, and the acid-base neutralization tank 4 faces the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com