Early-strength and high-impermeability lining concrete and preparation method thereof

A concrete and high-resistance technology, applied in the field of building materials, can solve problems such as concrete cracking easily, achieve important economic and environmental benefits, save resources and energy, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

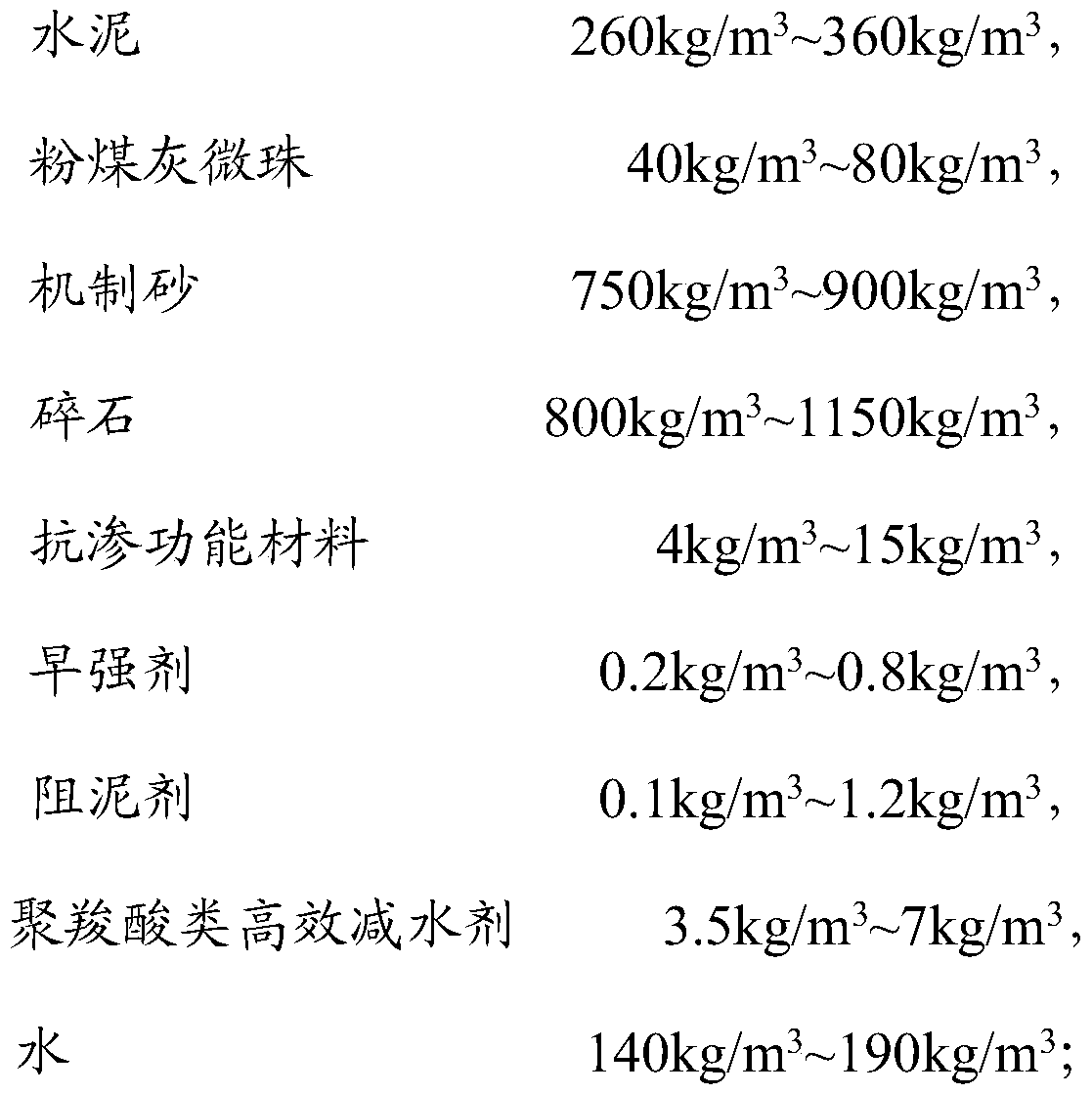

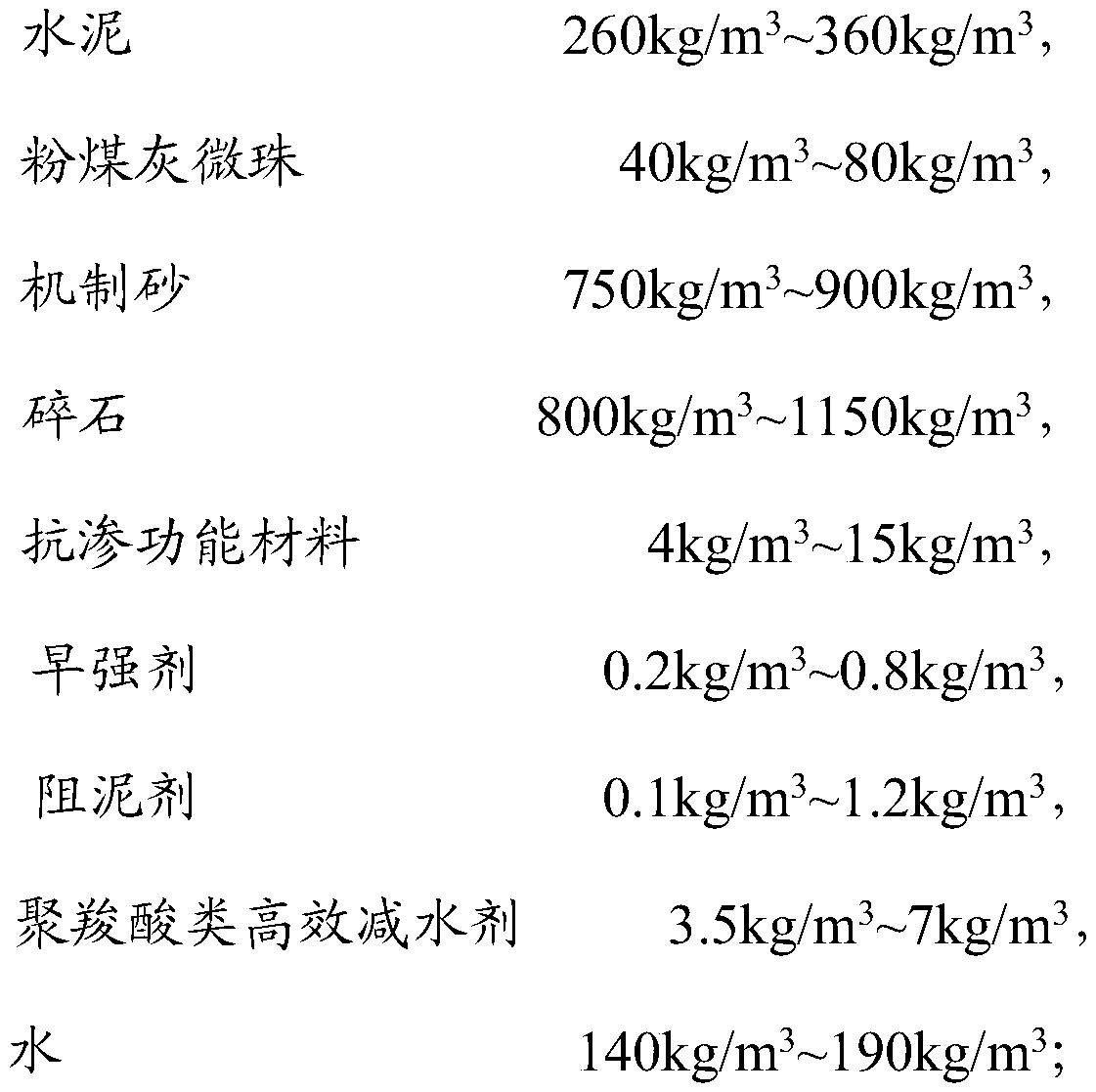

Method used

Image

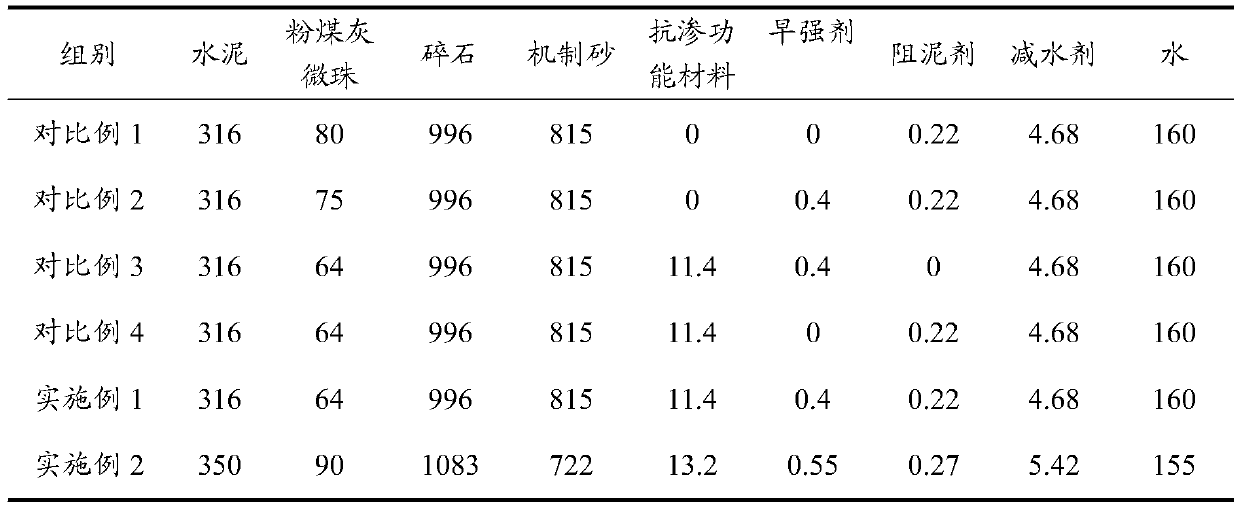

Examples

Embodiment 1~2

[0063] A preparation method of early-strength high-impermeability lining concrete (C30~C40), comprising the steps of:

[0064] (1) take each raw material by proportioning shown in table 1;

[0065] (2) Pour the weighed machine-made sand and gravel into the mixing pot and dry mix for 1 minute, then add cement, fly ash microbeads, and anti-seepage functional materials to continue dry mixing for 1.5 minutes, and mix the polycarboxylic acid After mixing high-efficiency water reducer, mud-repelling agent and water, slowly pour 70wt% of the amount into the stirring pot, and start stirring at the same time, stirring for 2 minutes, and slowly add the remaining 30wt% polycarboxylate high-efficiency water reducer, The mixture of silt inhibitor and water is continuously stirred for 1 minute to obtain a uniform mixture. Finally, it is poured into the mold. After 1 day of mold removal, standard curing is performed to obtain early-strength and high-impermeability lining concrete.

[0066] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com