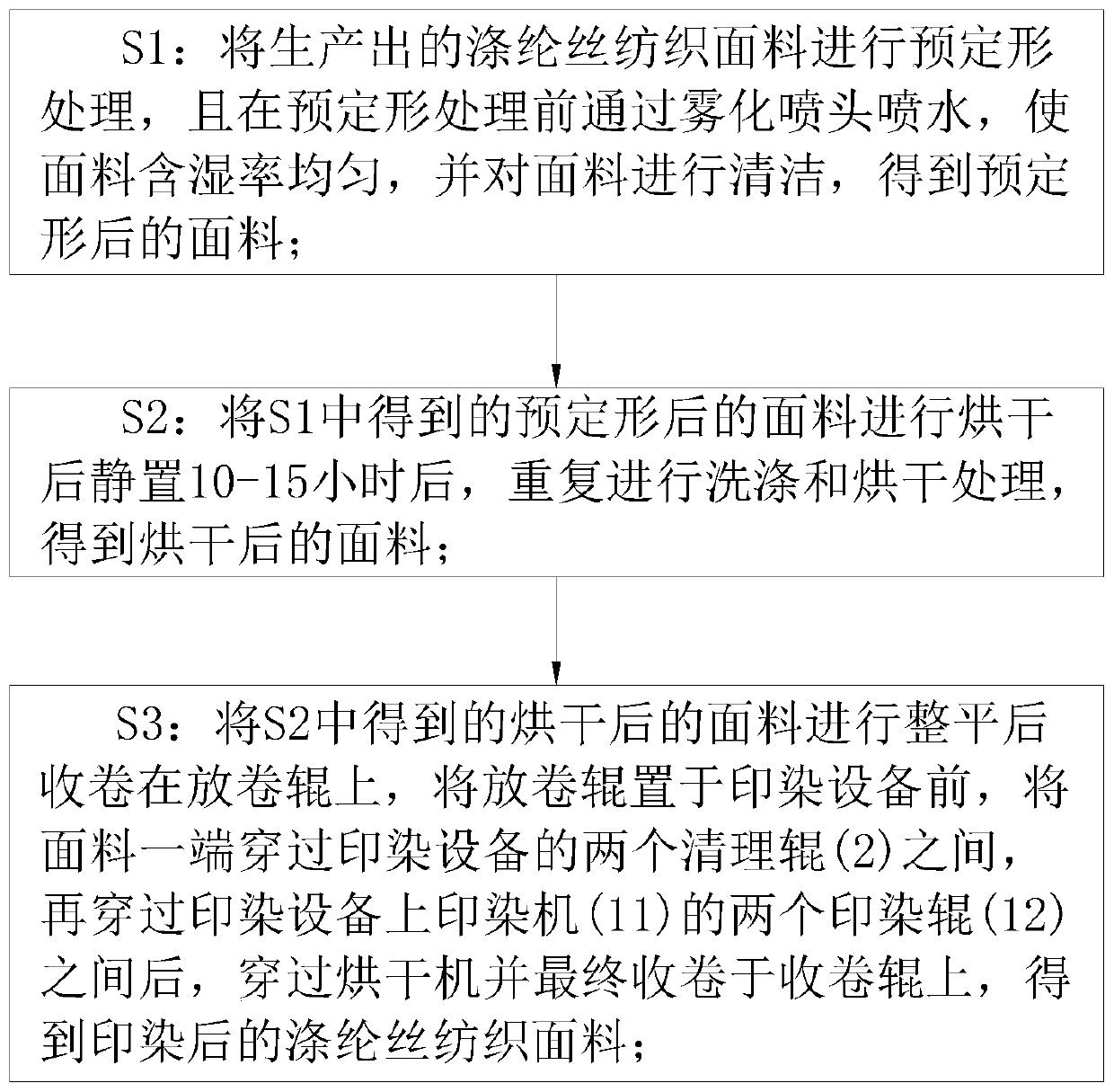

Printing and dyeing process for polyester silk textile fabric

A technology for textile fabrics, printing and dyeing processes, applied in the field of fabric printing and dyeing, can solve the problems of affecting the placement effect, short service life of surrounding equipment, and vibration, etc., to improve the efficiency of dust cleaning, reduce the difficulty of dust cleaning, and reduce the raising of dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

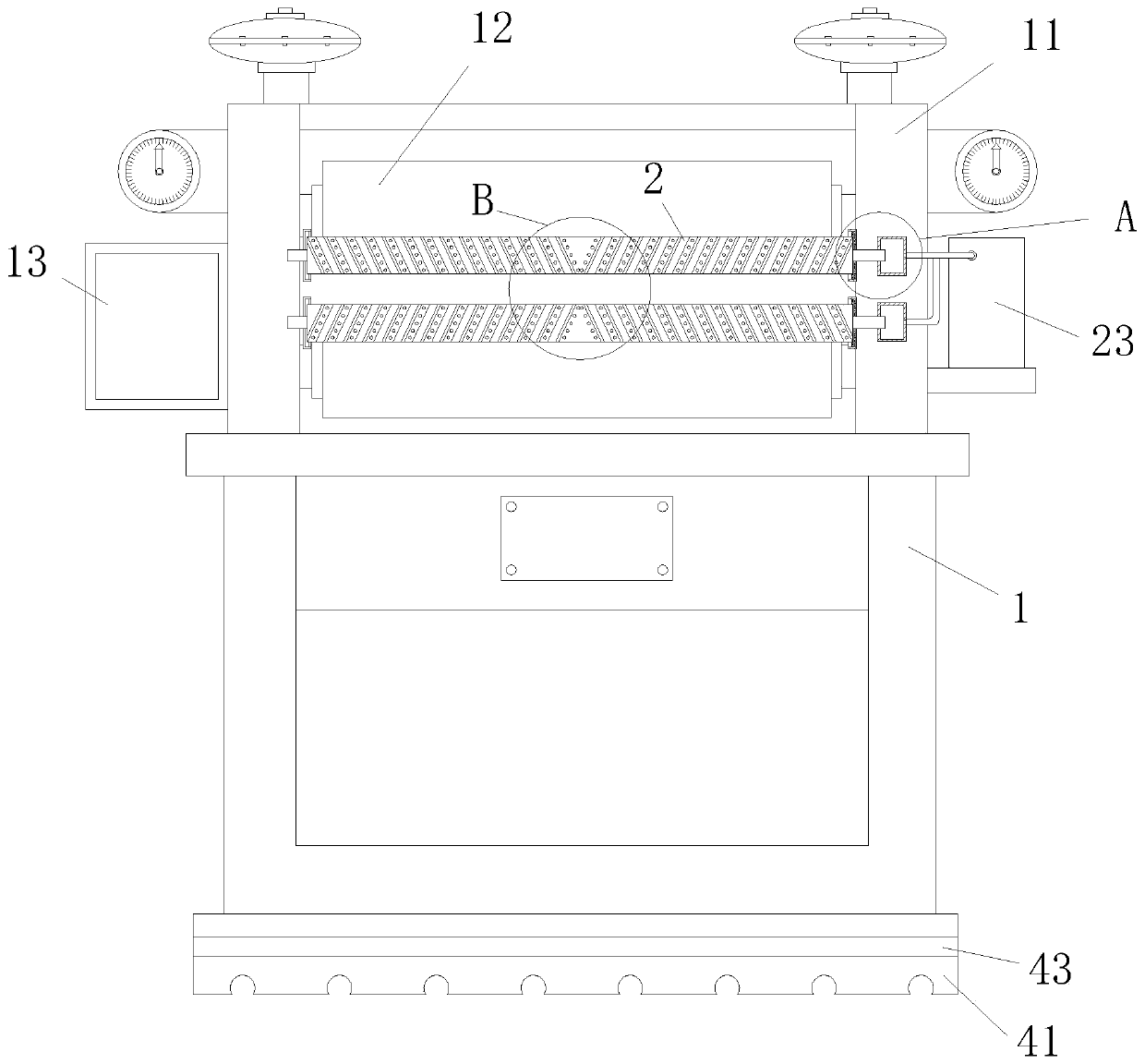

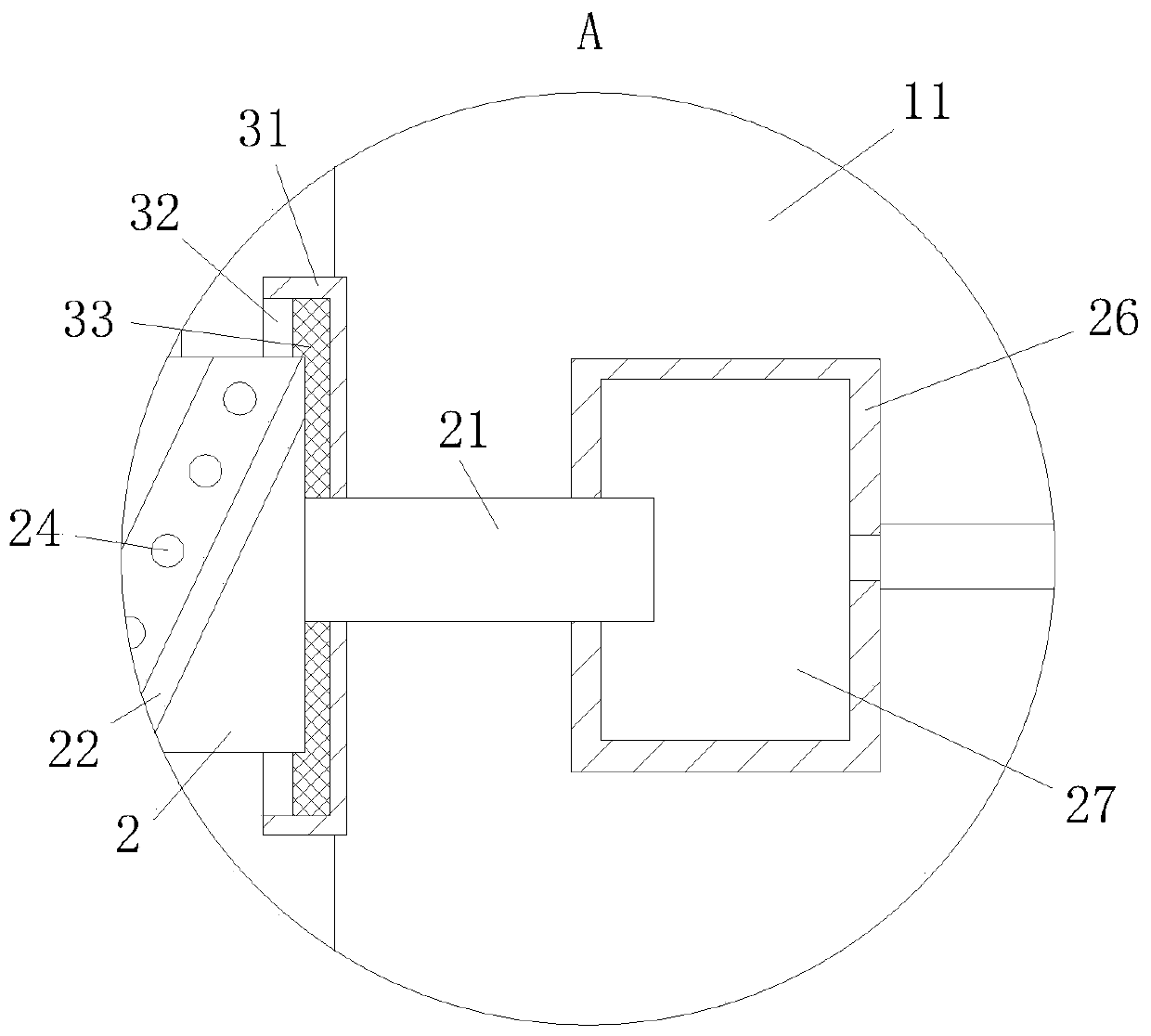

[0037] As an embodiment of the present invention, the lower surface of the body 1 is fixedly connected with a bottom plate 41 through evenly arranged buffer metal parts 4; the bottom plate 41 is made of rubber material; the upper surface of the bottom plate 41 is arranged with first Ash baffle 42; the lower surface of the body 1 is provided with a second ash baffle 43; the first ash baffle 42 and the second ash baffle 43 are arranged alternately and close to each other; it can effectively prevent dust from entering the bottom plate 41 between the machine body 1 and the equipment; the bottom surface of the bottom plate 41 is provided with evenly arranged semicircular buffer tanks 44; during operation, the printing and dyeing machine 11 vibrates during the working process, which drives the body 1 to vibrate, thereby passing through the bottom plate 41 The rubber material effectively provides cushioning for the machine body 1, preventing the dust from rising on the ground caused b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com