Mounting device and mounting method used for T-shaped joint nodular cast iron pipe

A cast iron pipe and interface ball technology, applied in the direction of pipe/pipe joint/pipe fitting, pipe laying and maintenance, passing through components, etc., can solve the problems of difficult installation, difficult disassembly, low work efficiency, etc. Light, easy to install, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

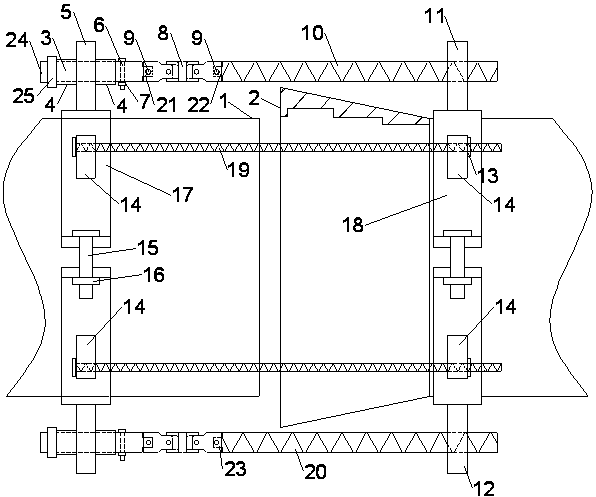

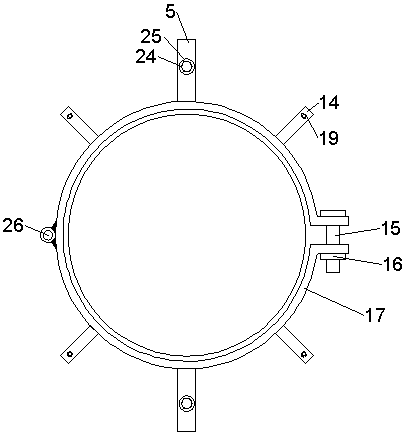

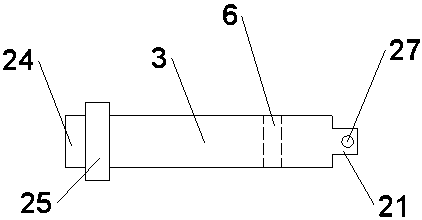

[0028] Such as figure 1 with figure 2 As shown, it is a schematic diagram and a side view of the overall structure of a quick installation device for ductile iron pipes with a T-shaped interface of the present invention, including two opening hoops, two power polished rods 3, four collars 4, and two three-section universal joints 8. Four power steel blocks, eight auxiliary steel blocks 14, two power screws, four auxiliary screw rods 19 and several sets of bolts and nuts. The opening hoop is composed of a torque input hoop 17 and a torque output hoop 18. The torque Both the input hoop 17 and the torque output hoop 18 contain a hinge 26, the hinge 26 is located at the symmetry of the upper opening of the hoop, the torque input hoop 17 and the torque output hoop 18 are fastened by the hoop bolt 15 and the hoop Tightening nut 16 is fastened, and the hole of the unthreaded through-hole steel block 5 that is welded symmetrically on the torque input hoop 17 is connected with the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com