Cargo loading vehicle and airport checked baggage automatic carrying system

A technology for loading vehicles and goods, applied in the direction of loading/unloading, conveyors, conveyor objects, etc., can solve the problems of consumption, large manpower, luggage damage, etc., achieve high safety factor, increase the speed of cargo transportation, and reduce collisions and damages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

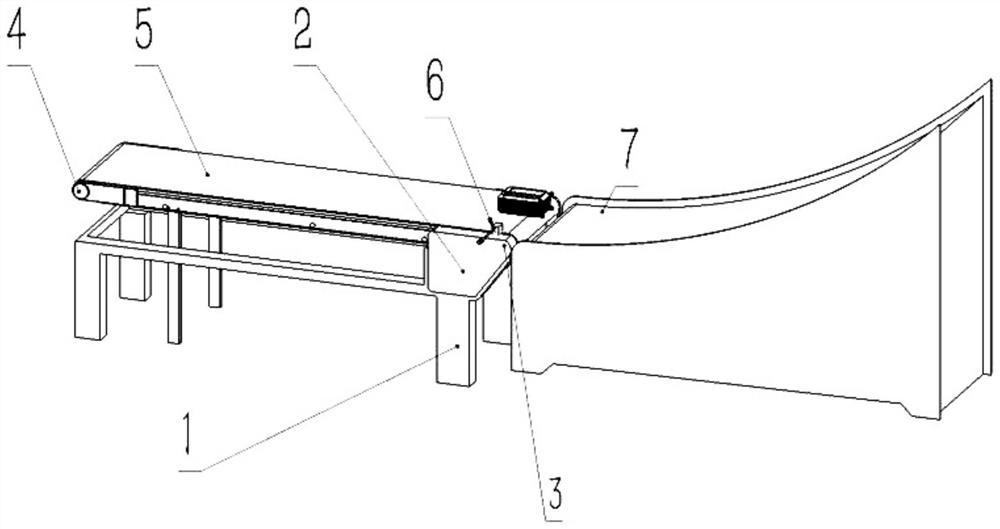

[0058] Example 1: Baggage is shipped from the airport sorting channel to the flight cabin process

[0059] 1, loading process

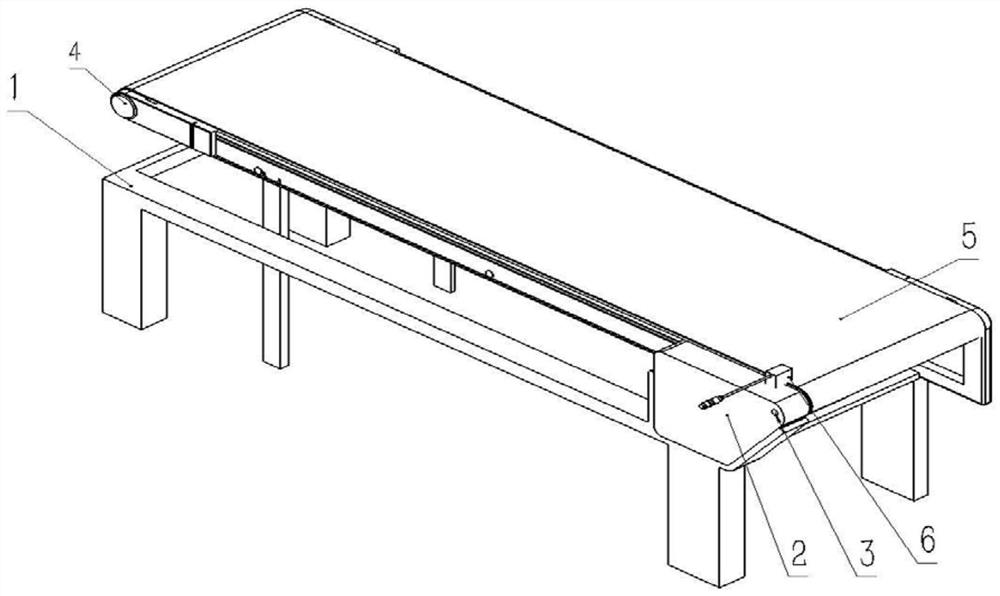

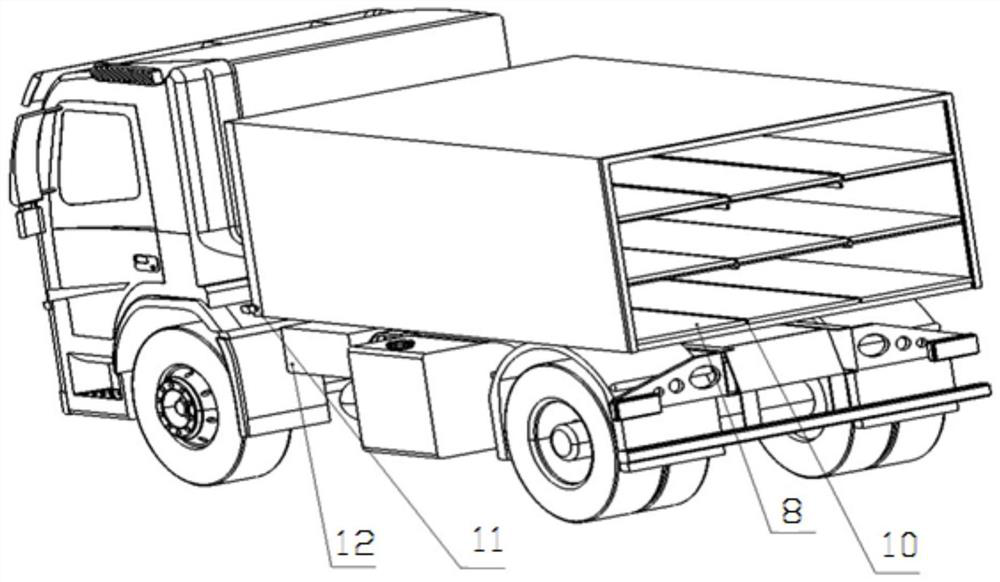

[0060] Such as Figure 10 As shown, when the baggage is sorted from the airport sorting slot, it operates with a longer continuous conveyor belt. Each of the baggage is continuously transmitted with a photoelectric sensor, the continuous transmission belt is running a distance, so that the luggage is put on a continuous conveyor belt, waiting for the load car to transport the baggage. Loading the baggage by a reasonable time load, the continuous transmission belt makes it run, and the baggage that is transported to the carrier is transported to the tail of the carriage via the loading vehicle tail plate device; the spindle motor at the bottom of the car, and controls the electromagnetic clutch, so that A sorting zone is running; two photoelectric sensors are installed at each sorting belt within the carriage, and the operation of the conveyor belt is contr...

Embodiment 2

[0063] Example 2: The process of luggage from the plane to the passenger

[0064] 1, loading process

[0065] The luggage is transported from the aircraft cabin, and the carrier is loaded with the airport. This loader is connected to the airport. The luggage is transferred from the transfer car from the transfer vehicle via the tail plate device to the loading vehicle. process.

[0066] 2, unloading process

[0067] Loading car transports baggage to the airport to unload the tip tip, the motor spindle is reversed on the motor, so that the sorting belt in the car is reversed, and the baggage is sent out, and the baggage is transported to the continuous conveyor belt, and the continuous conveyor belt Luggage turntable, waiting for passengers to collect.

[0068] Note: The maximum size of the airport checked baggage is: 40 * 60 * 100cm, the maximum weight is: 50kg. In general, the size of the car weight is 7.4 meters long, 2.2 meters wide, 2.2 meters high, if the 7-meter long truck i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com