Construction method for rapid underwater repair of leakage cracks of concrete faced rockfill dam and repair structure of construction method

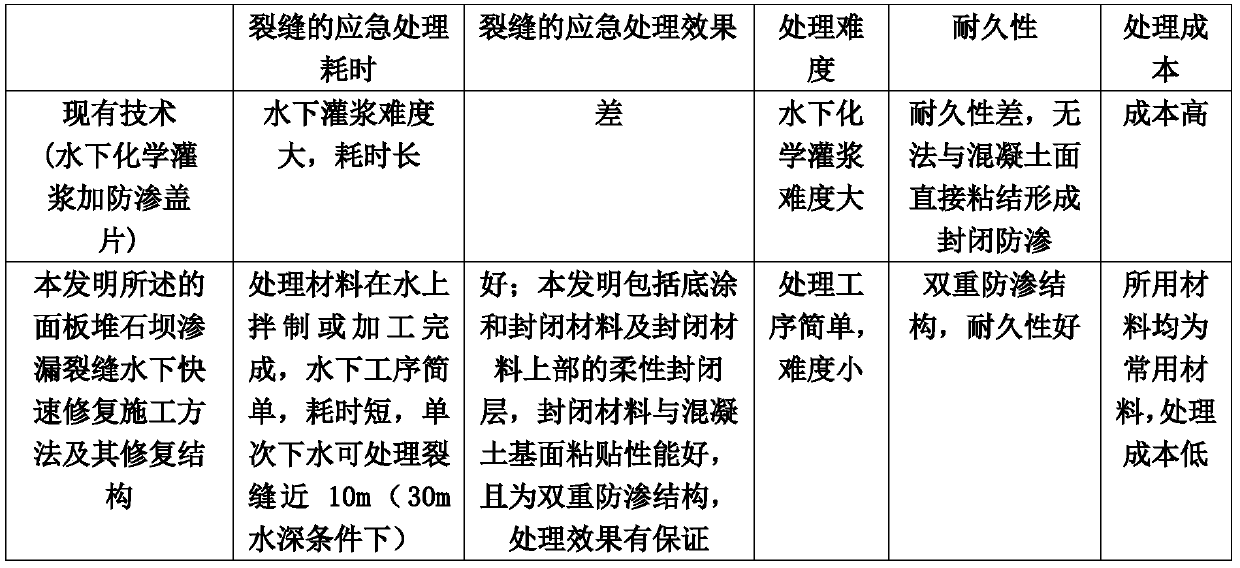

A technology of face rockfill dams and construction methods, applied in water conservancy projects, dams, barrages, etc., can solve the problem of underwater crack emergency treatment. There is no efficient and fast repair structure, the difficulty of treatment and durability are difficult to guarantee, underwater chemistry The difficulty of grouting and other problems, to achieve the effect of high construction efficiency, reliable anti-seepage, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

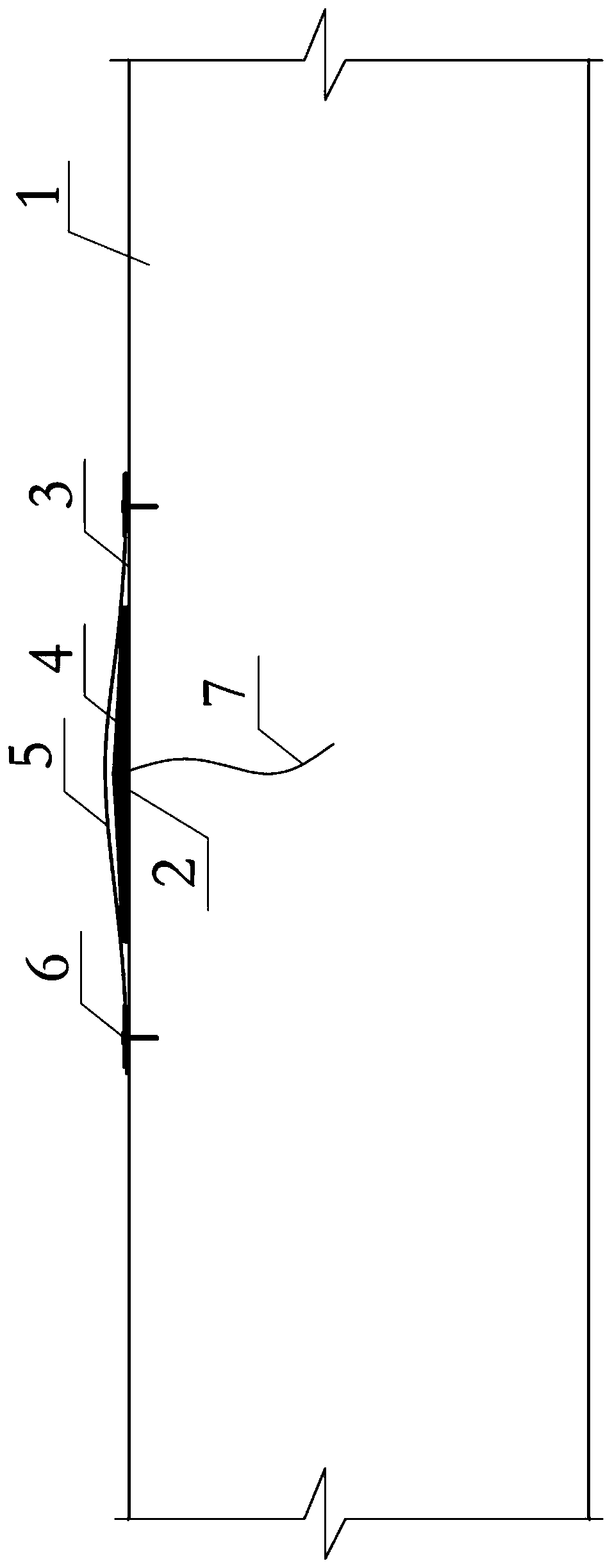

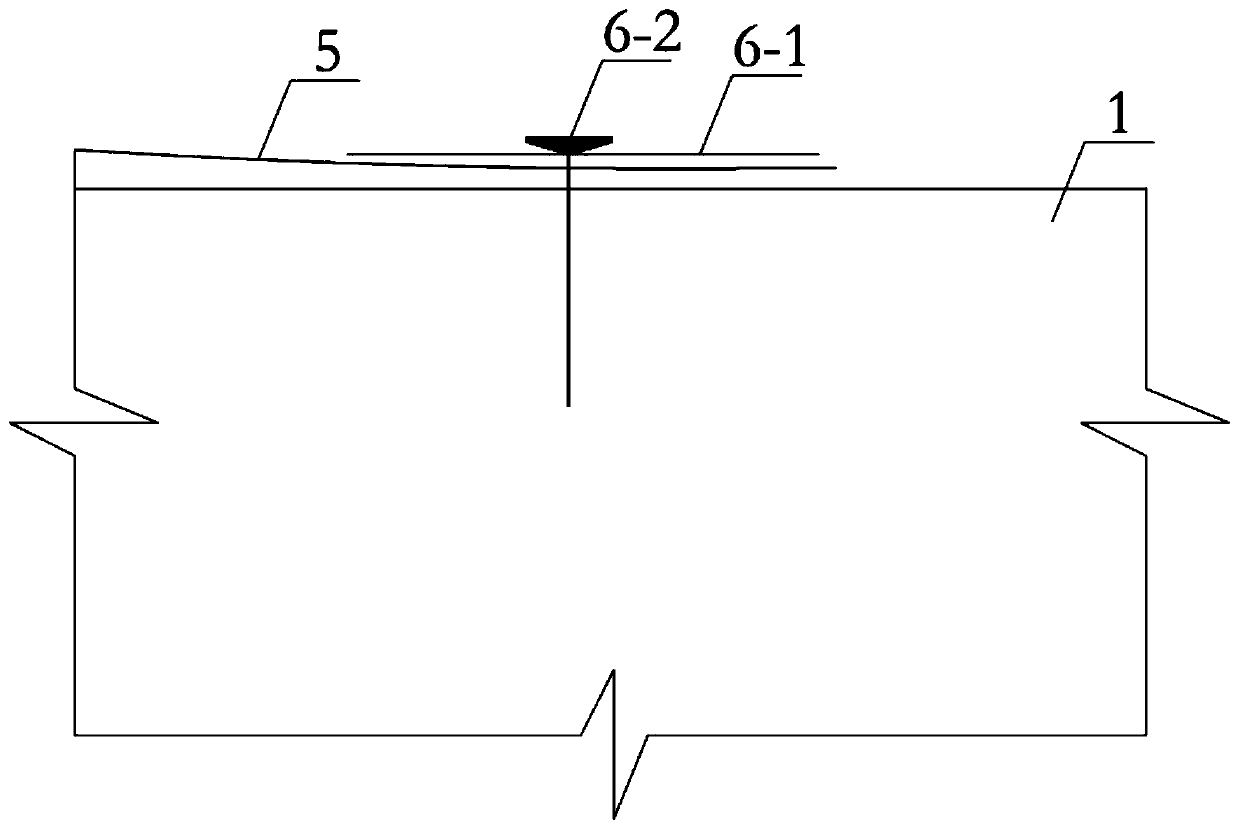

[0041] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0042] Referring to the accompanying drawings, it can be seen that the underwater rapid repair construction method of seepage cracks in face rockfill dams consists of the following steps executed in sequence,

[0043] Step 1: The diver carries a high-pressure water jet sandblasting gun into the water above the crack 7 to be repaired, and rinses along the crack 7 from top to bottom. During the flushing, the diver walks slowly under the traction of the guide rope on the shore to ensure that the concrete base 3 is rinsed clean ;

[0044] Step 2: After the washing is completed, the diver comes out of the water, and after the water body is left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com