Rope rewinding machine mounting bracket of petroleum drilling machine

A technology for installing brackets and rewinding machines, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc. It can solve the problems of easy vibration, shaking of the transmission shaft, poor stability, etc., and achieve the effect of stable transmission and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

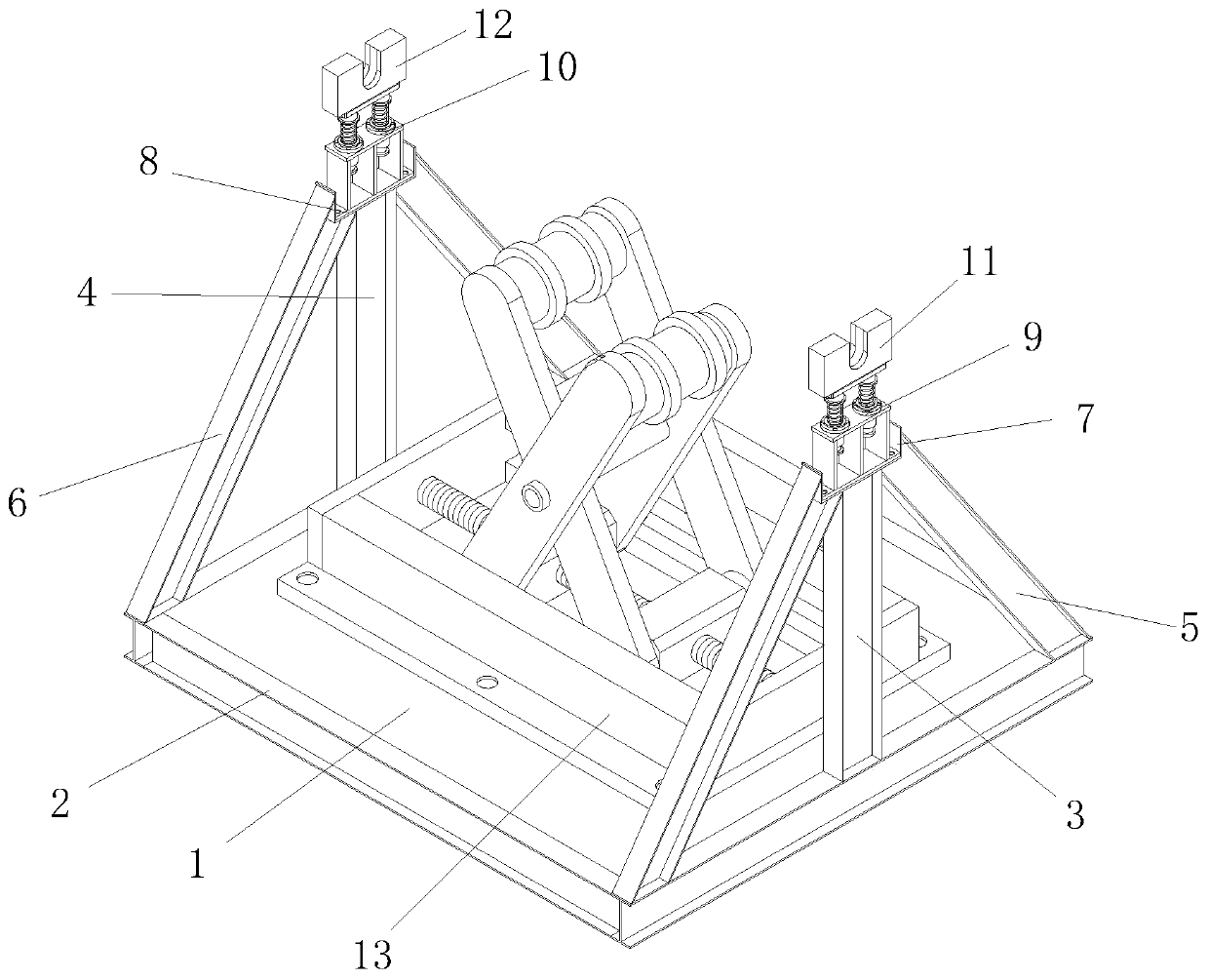

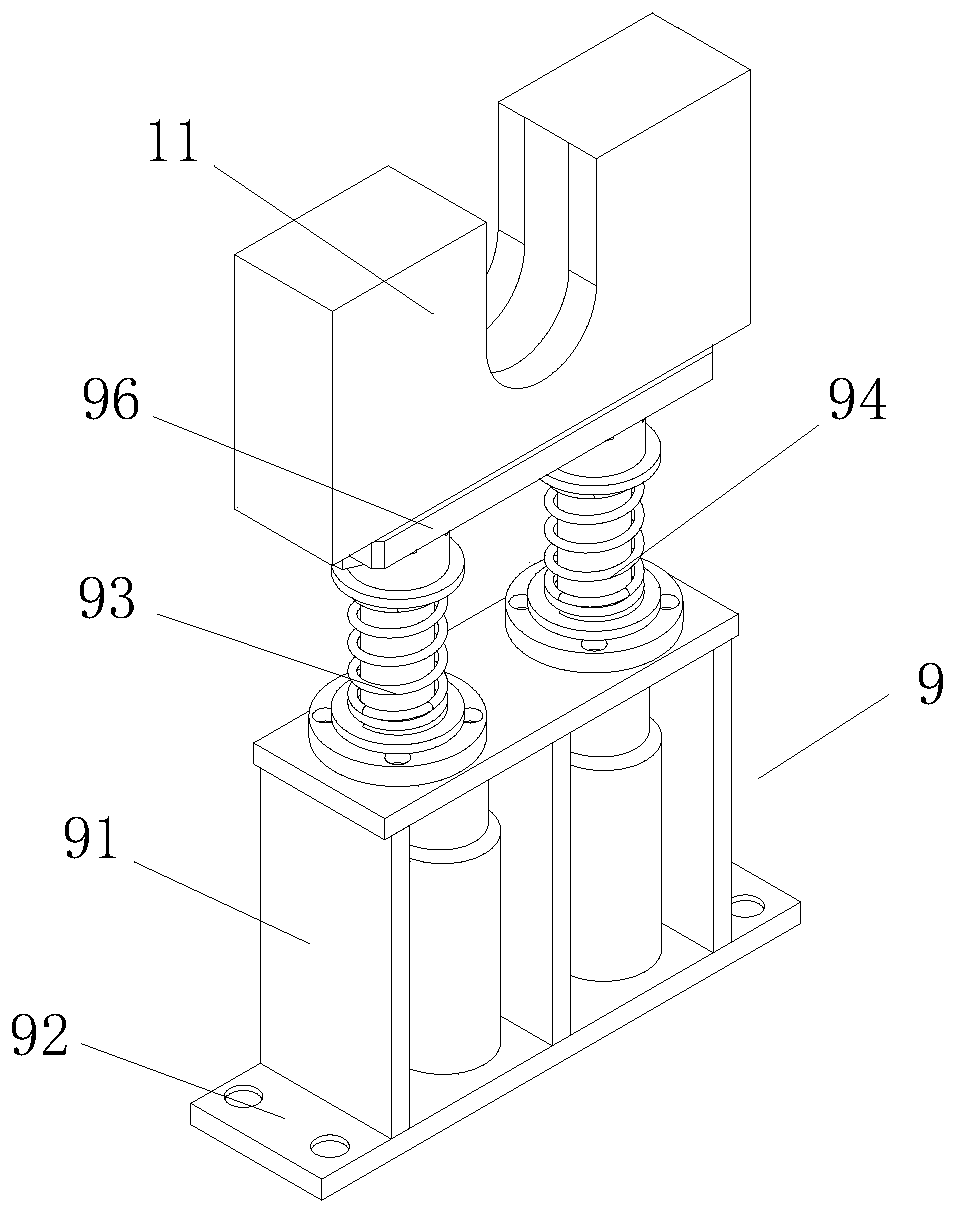

[0032] see figure 1 As shown, the present invention provides a kind of rewinding machine mounting bracket of an oil drilling rig through improvement, including a base plate 1, a base frame 2, a first support stand 3, a second support stand 4, and a left inclined frame plate 5 , the right inclined frame plate 6, the first frame seat 7, the second frame seat 8, the first external fixture 11, the second external fixture 12, the first buffer shock absorber 9, the second buffer shock absorber 10 And guiding auxiliary support device 13, the outer periphery of base plate 1 is provided with base outer frame 2 for auxiliary support, and the upper and middle parts of both sides are provided with first support stand 3 and second support stand 4 respectively, are used to support the inverted rope The drive shaft rod of the machine, the first support stand 3 and the second support stand 4 are respectively equipped with a left inclined frame plate 5 and a right inclined frame plate 6, which...

Embodiment 2

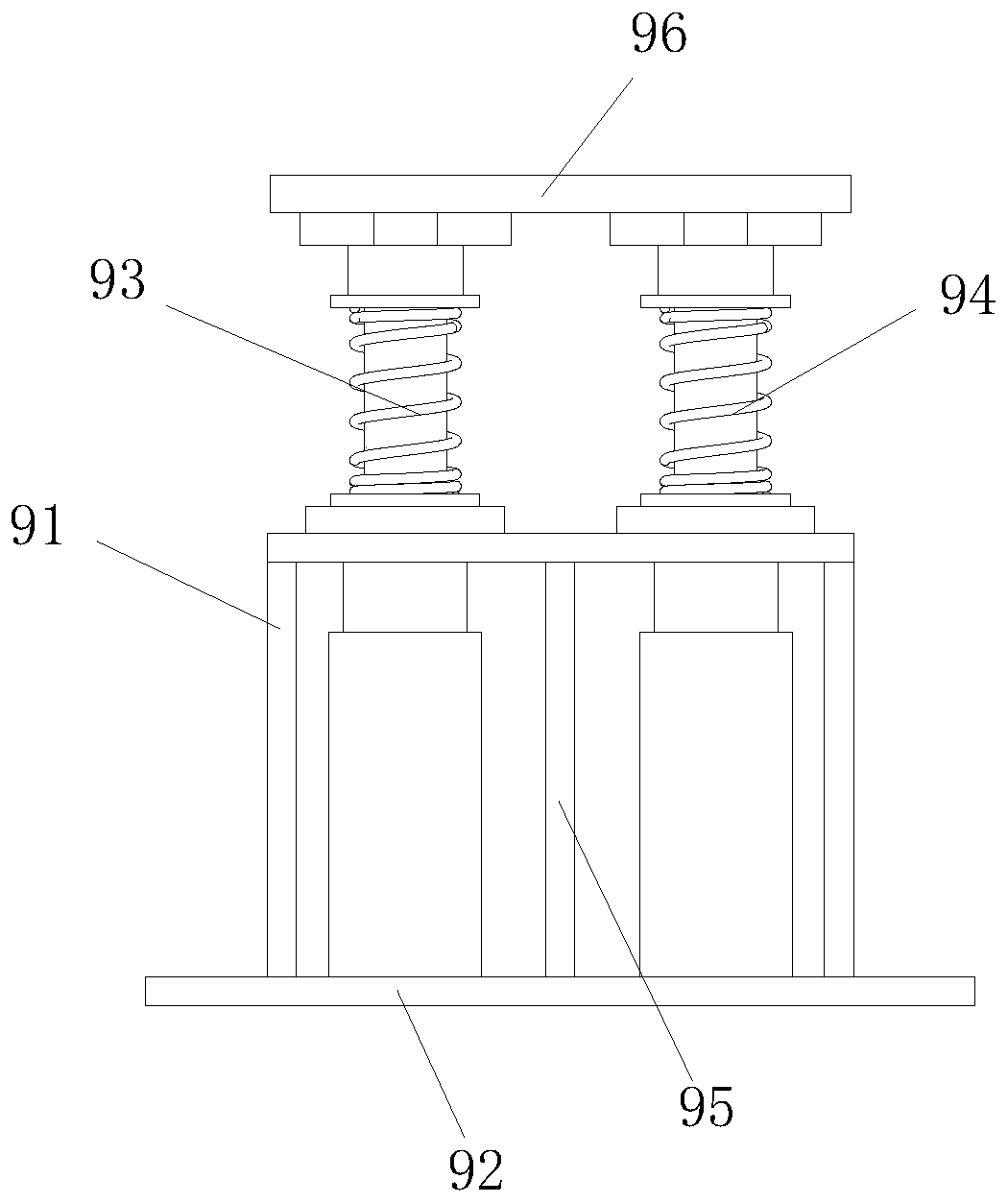

[0038] The present invention provides a rope reversing machine mounting bracket for an oil drilling rig through improvement. The right support guide wheel 135 and the left support guide wheel 136 are arranged in parallel with the installation grooves in the middle of the first external fixing part 11 and the second external fixing part 12. It is convenient to install the transmission shaft of the external rope reversing machine. The hollow rectangular frame structure in the middle of the positioning frame 91 is convenient for the telescopic work of the first buffer mechanism 93 and the second buffer mechanism 94. The lower end of the telescopic sleeve 933 and the inner side of the upper end of the base tube 934 and the inside of the telescopic sleeve 933 is the same as that of the base cylinder 934, so that the telescopic movable rod 931 can perform telescopic activities in the telescopic sleeve 933 and the base cylinder 934, and the bottom plate 935 is pressed down to match the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com