Medium-specific-rotation-speed double-outlet volute pump

A dual-outlet, specific speed technology, used in pumps, pump components, non-variable-capacity pumps, etc., can solve problems such as design optimization of the number of volute outlets, achieve good hydraulic performance and operating efficiency, enhance speed components, and improve water flow. the effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

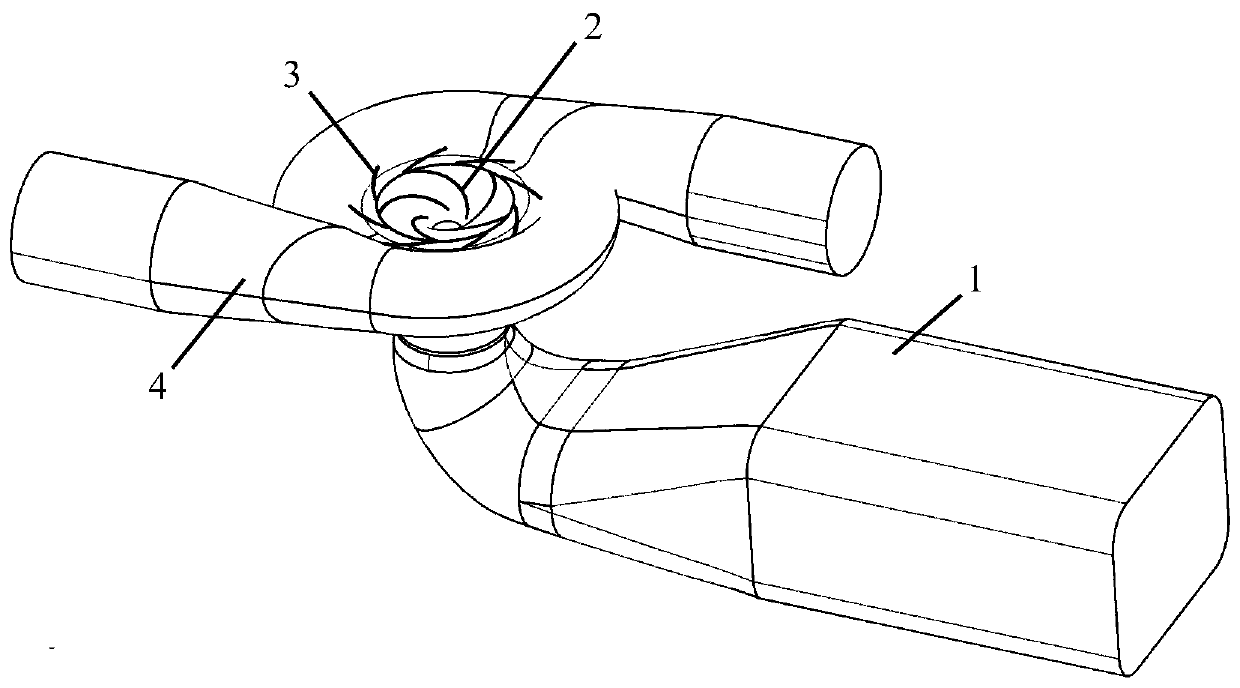

[0115] To optimize the design of a pump, the design head of the pump is 49m, and the design flow rate is 435m 3 / h, the specific speed is 137.

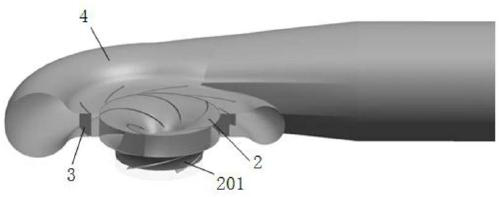

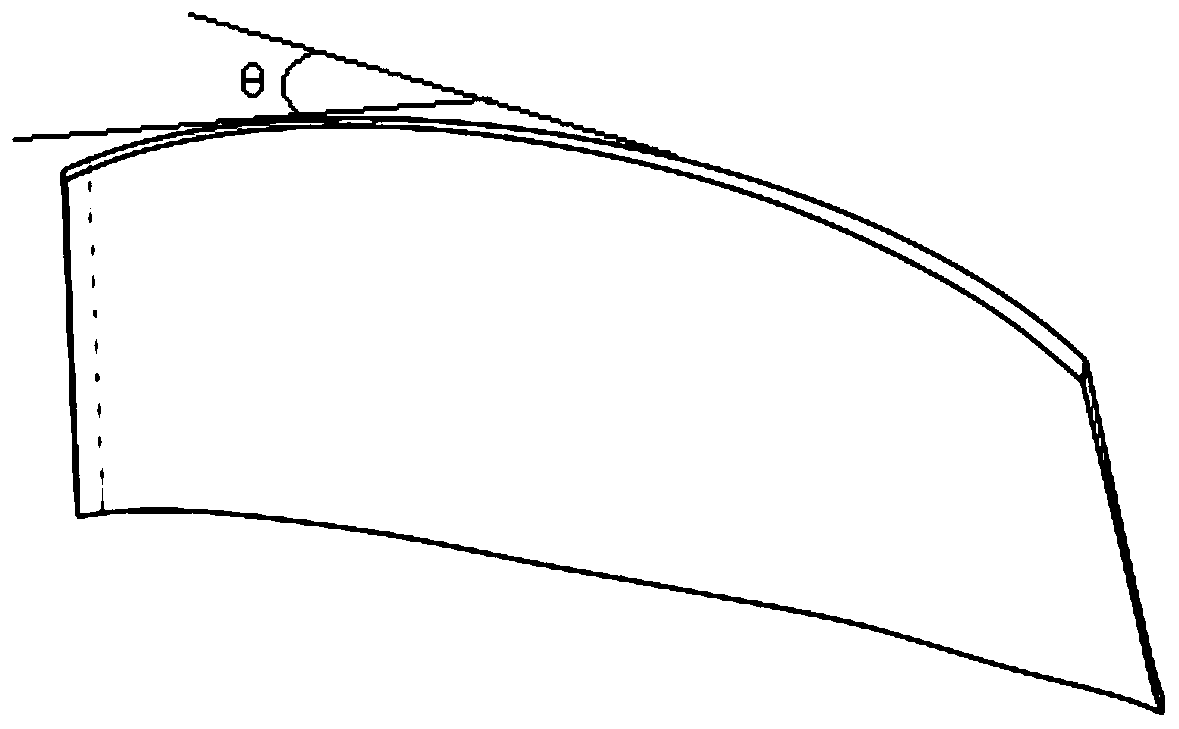

[0116] Such as Figure 5-6 As shown, the optimized parameters of the present invention are: the diameter of the inlet at the bottom of the impeller is 260mm, the diameter of the outlet at the top of the impeller is 360mm, the number of blades of the impeller is 5, and the blade of the impeller adopts a back-curved non-equal-thickness twisted structure, and the back-bend angle is 40°. Eight deflectors are set at the water inlet of the volute, and the cross section of the water outlet of the double outlet volute is a circular section with a diameter of 350mm, which is directly connected to the outlet pipe.

Embodiment 2

[0118]The specific application process of the present invention is: the pump body and the water suction pipe 1 are filled with water first, the motor drives the impeller 2 to rotate, the water between the blades in the impeller starts to rotate, and the water is thrown from the center of the impeller 2 to the outer edge of the impeller and at a higher speed The pressure is discharged from two water outlets. At the same time, due to the pressure difference, the impeller 2 keeps rotating, and the liquid also continuously enters from the water suction pipe 1 and flows out from the two water outlets through the double-outlet volute 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com