Fan coil pipe heat exchanger

A fan coil and heat exchanger technology, applied in indirect heat exchangers, heat exchanger shells, heat exchanger types, etc., can solve the problems of noise generated by fan devices, affecting heat exchange efficiency, and easy to generate water, etc. Achieve the effect of preventing clogging, speeding up heat exchange efficiency and improving filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

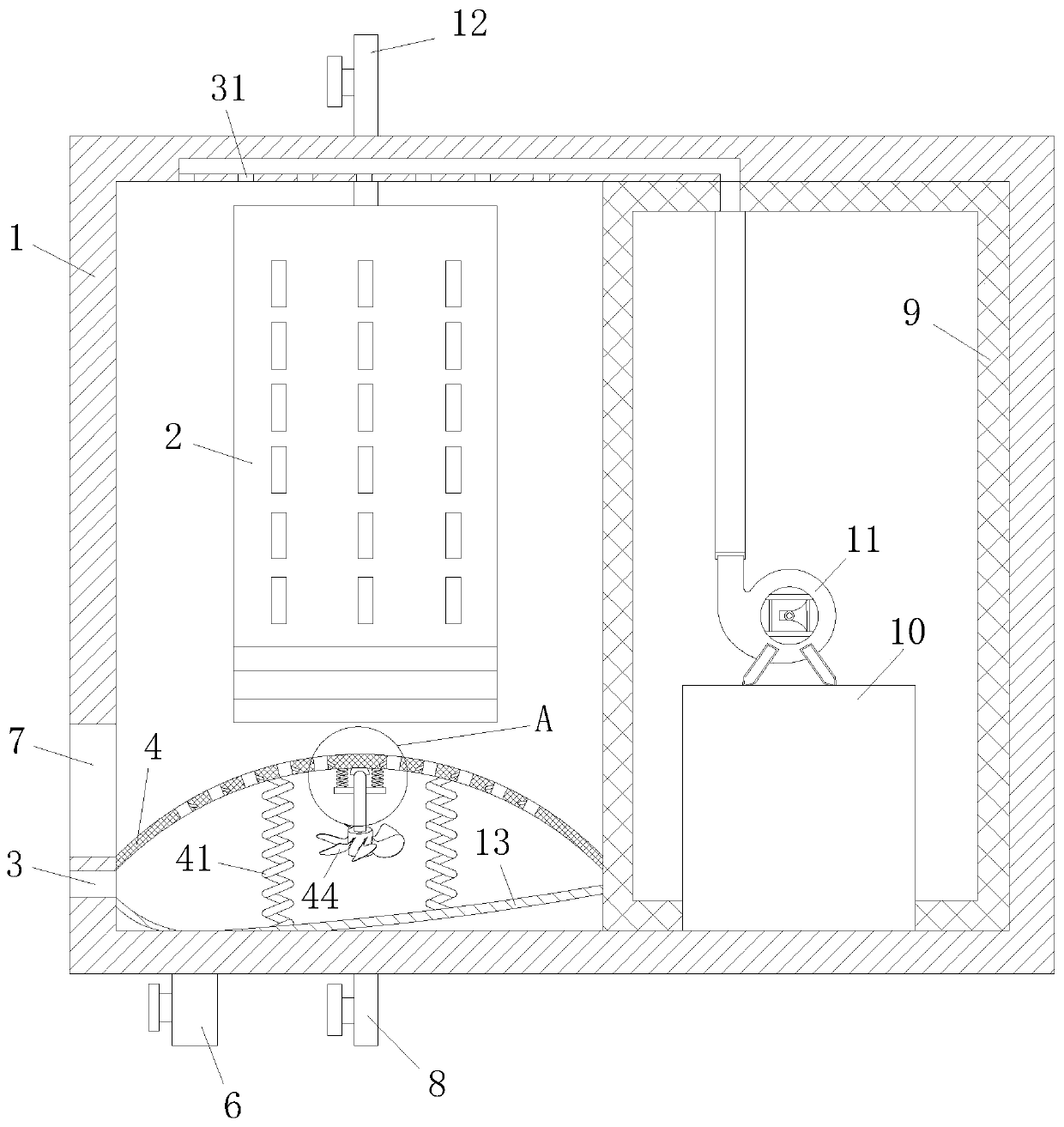

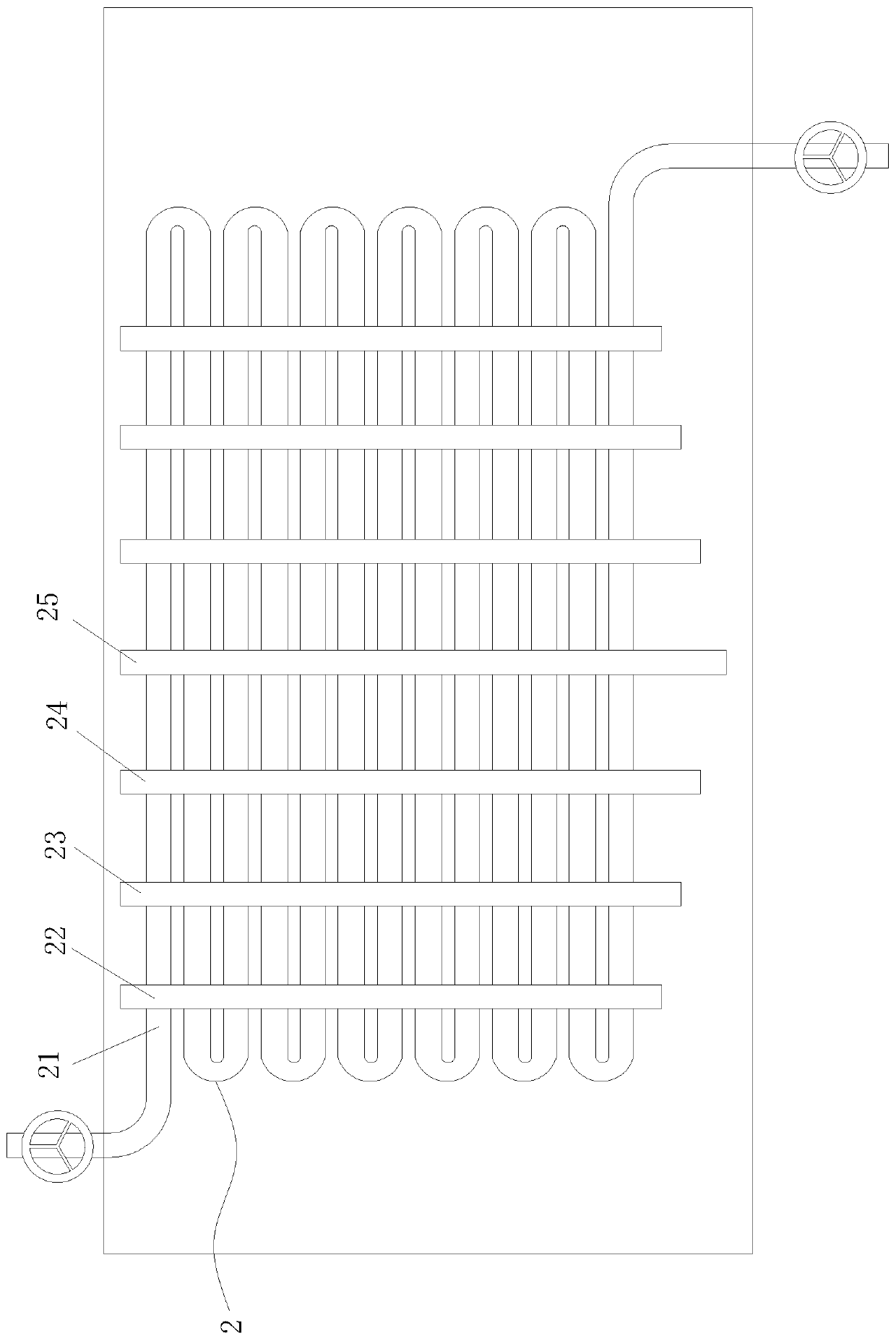

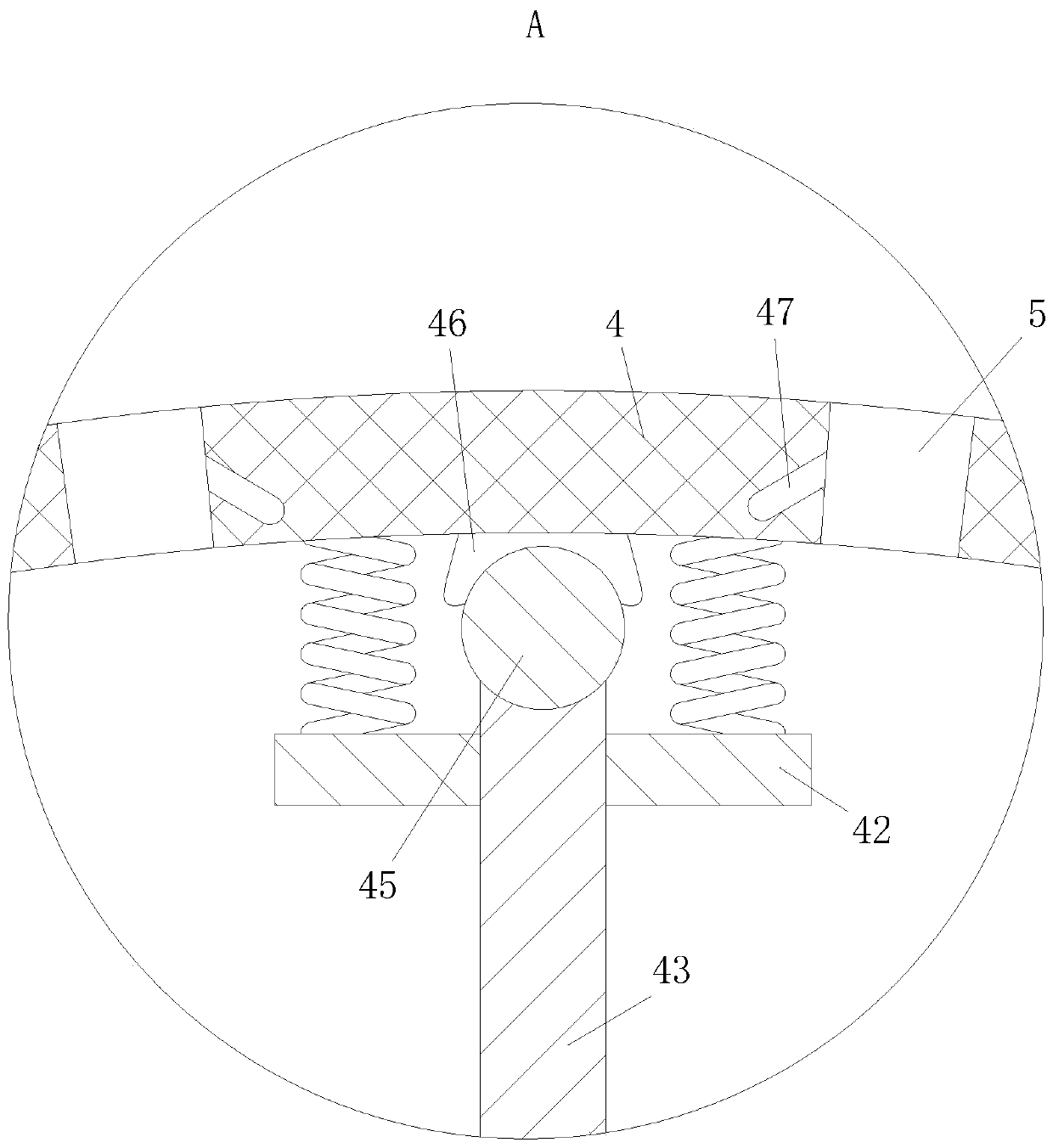

[0029] As a specific embodiment of the present invention, the coil pipe 21 runs through the first fin 22, the second fin 23, the third fin 24 and the fourth fin 25 to form a ring-shaped structure, and the first fin The tops of the sheet 22, the second fin 23, the third fin 24 and the fourth fin 25 are at the same level, and the first fin 22, the second fin 23, the third fin 24 and the fourth fin 25 The height of the bottom of the bottom from the ground gradually decreases; when working, because the first fin 22, the second fin 23, the third fin 24 and the fourth fin 25 are arranged in layers according to the height of the bottom from the ground, the condensation The dew will gradually flow from the first fin 22 which is higher at the bottom to the fourth fin 25 which is lower at the bottom step by step, and then slowly flow into the bottom of the device, so that the flow rate of dew can be delayed and water accumulation can be avoided Sudden excessive flooding of the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com