An Adaptive Super-Efficient Gas-Liquid Separator for Parallel Compressor Units

A gas-liquid separator and compressor unit technology, applied in compressors, refrigerators, refrigeration components, etc., can solve the problems of increased oil cooling load, increased compressor discharge temperature, low flow rate of the outlet pipe, etc., and achieve volume reduction , reducing the external size, the effect of improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

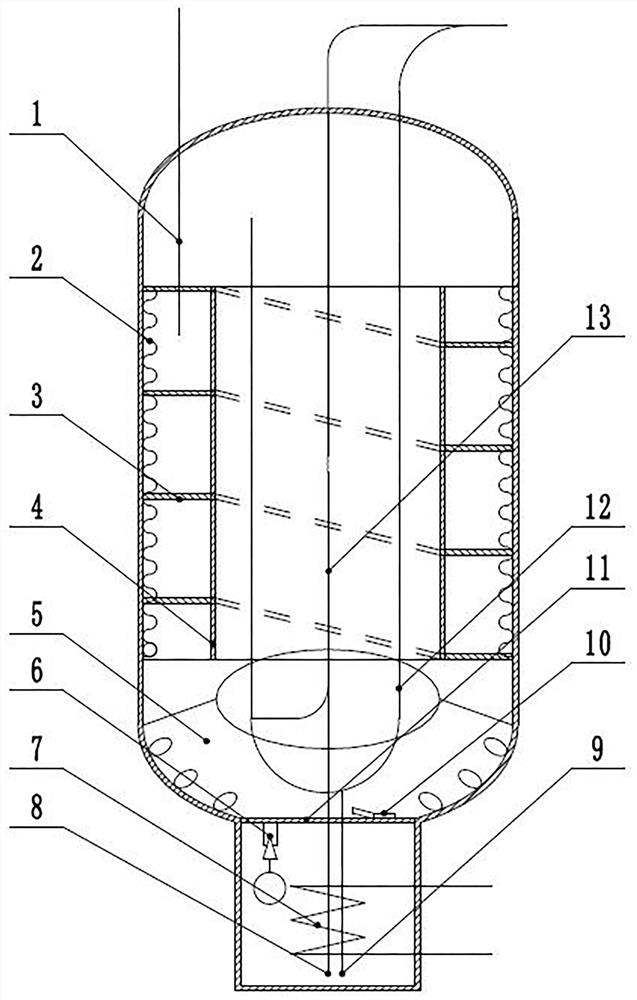

[0025] Such as figure 1 , an adaptive ultra-high-efficiency gas-liquid separator for a parallel compressor unit, comprising a shell in which a separation chamber, a diversion chamber and a collection chamber are arranged from top to bottom. The separator also includes an air intake pipe 1, an air outlet pipe and an oil return pipe.

[0026] A vertical inner cylinder 4 is arranged in the centrifugal cavity, and the inner cavity part of the inner cylinder 4 is a gravity separation cavity, and a centrifugal separation cavity is formed between the inner cylinder 4 and the housing, and a spiral cavity is arranged in the centrifugal separation cavity. Plate 3 constitutes a centrifugal spiral channel. The side wall of the centrifugal separation chamber is provided with a corrugated wire mesh thin layer 2 for trapping liquid.

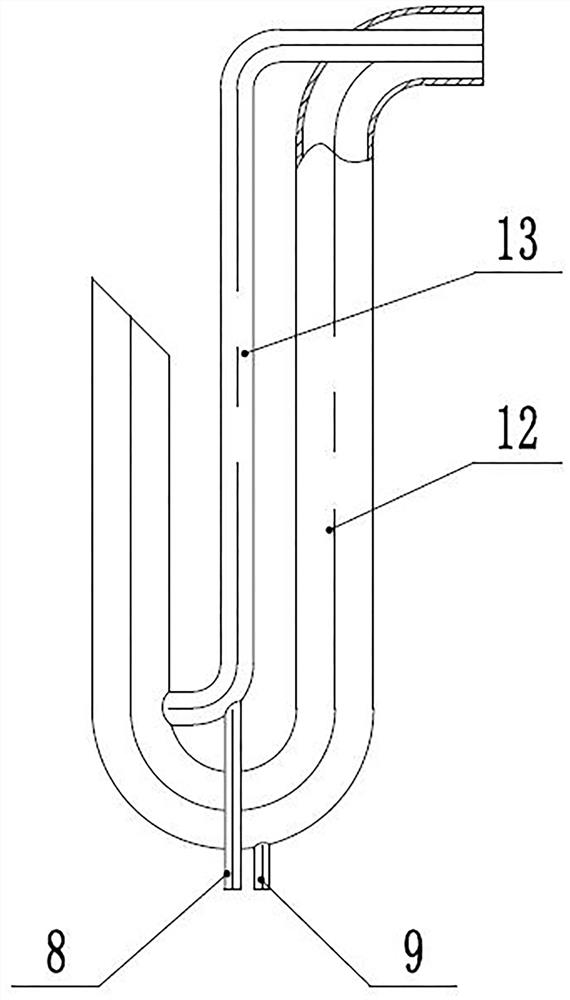

[0027] The outlet end of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com