A cooling device for anti-meshing of bearing rings after forging

A technology of a bearing ring and a cooling device, applied in the field of cooling devices, can solve problems such as unfavorable production, time-consuming site storage, easy wear and tear of conveyor belts, etc., achieving the effects of strong automation, reducing energy consumption, and avoiding uneven cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

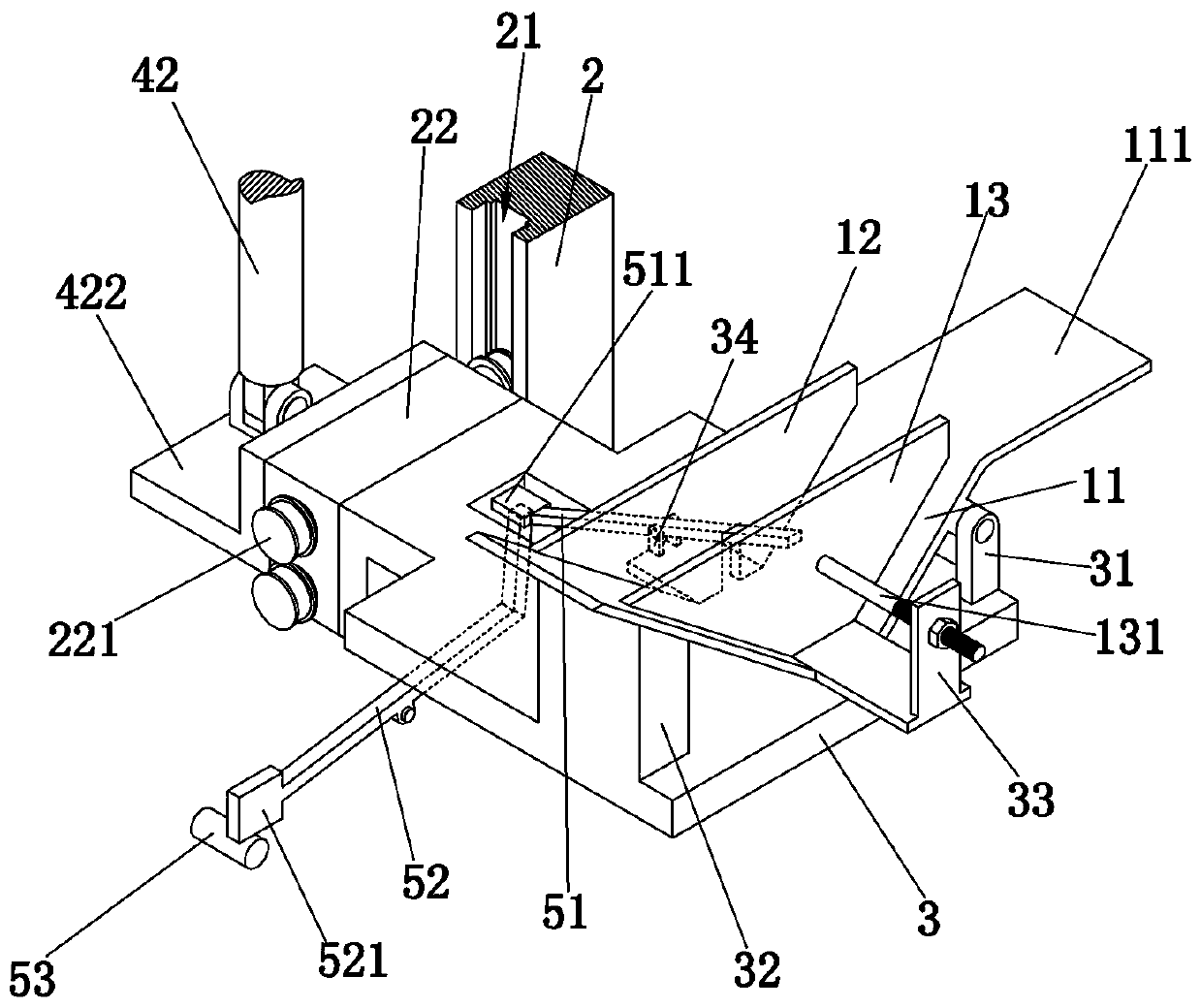

[0028] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

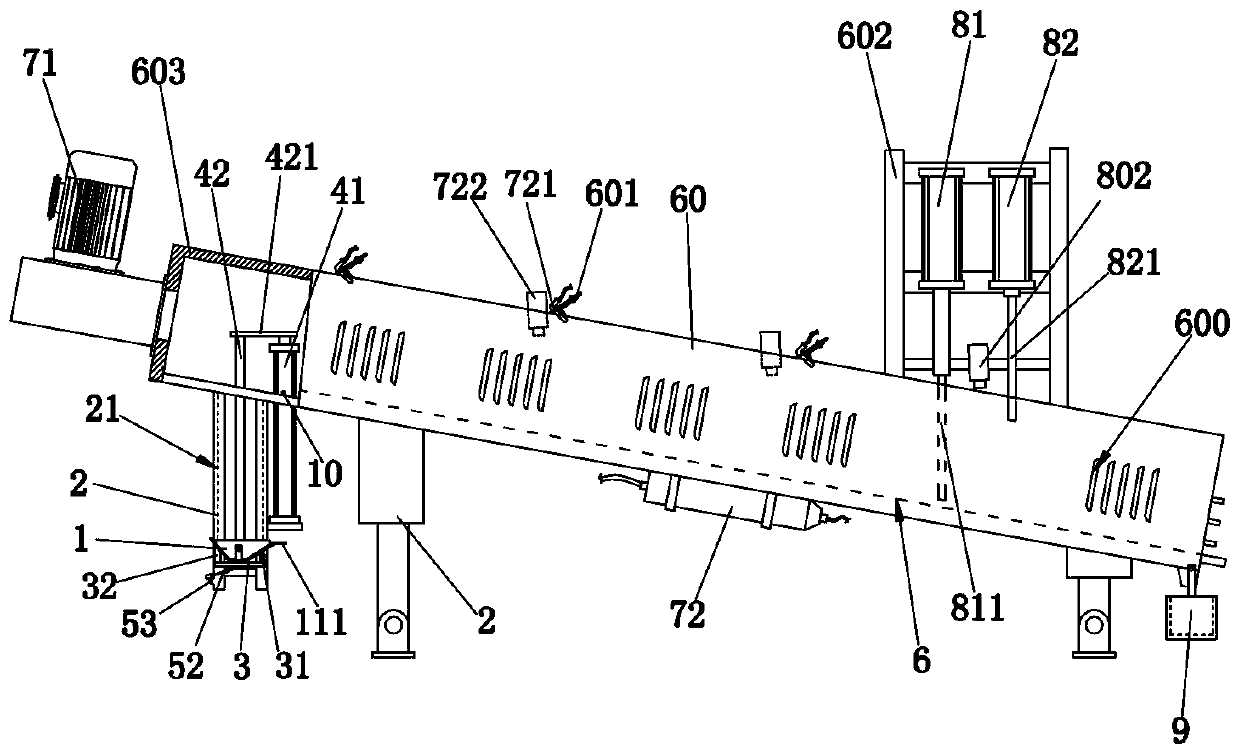

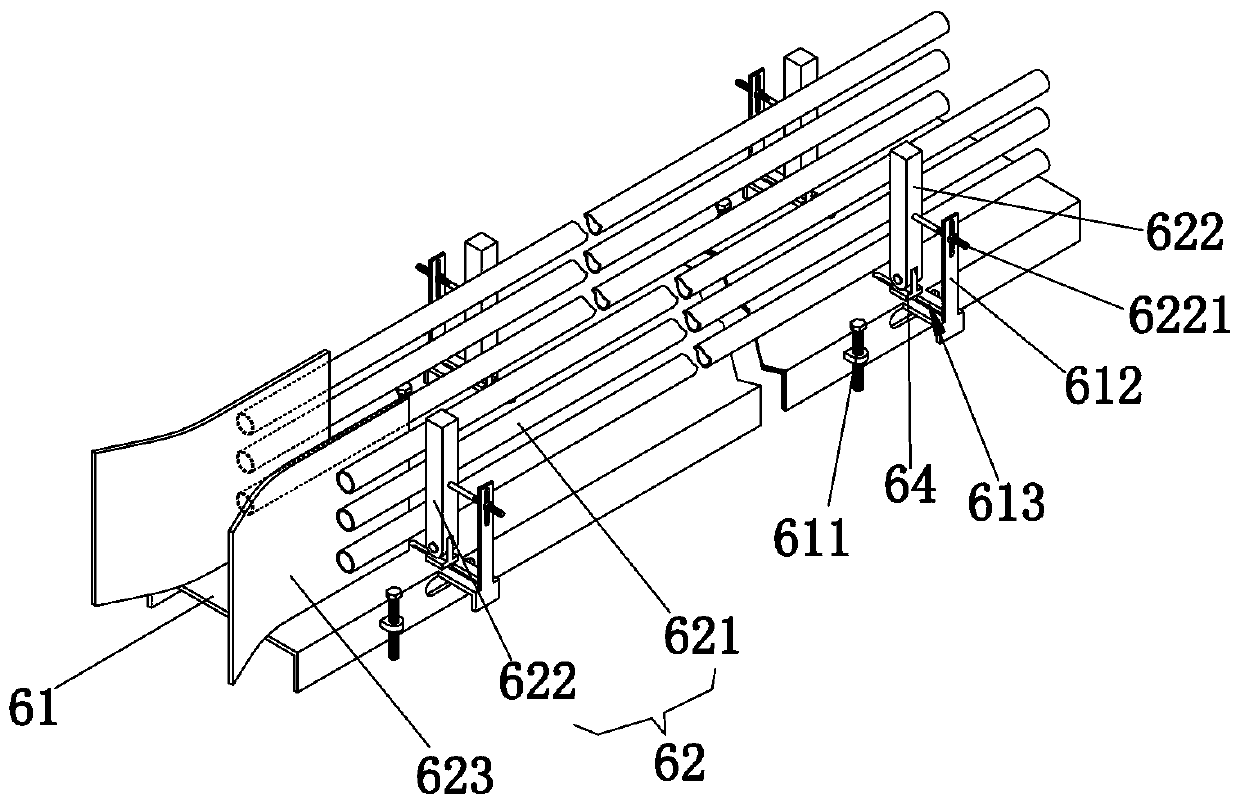

[0029] refer to figure 1 and Figure 4 , a cooling device for anti-meshed bearing rings after forging, including a frame 2, a feeding part, a cooling part and a discharging part. Wherein, the above-mentioned cooling part includes an atomizer 72 and a box body 60 . The box body 60 is arranged on the frame 2 obliquely in the left and right directions, and as a preferred solution: the box body 60 is arranged on the frame 2 so that the inclination can be adjusted. The box body 60 is provided with an inlet and an outlet, and a track 6 for the bearing ring a to roll is arranged inside the box body 60 . The box body 60 is provided with a plurality of nozzles 721 and first temperature sensors 722 arranged at intervals along the length direction of the track 6 directly above the track 6 . Each nozzle 721 communicates with the atomizer 72 and is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com