Gyroscope testing system and method

A test system and gyroscope technology, applied in the field of gyroscopes, can solve problems such as being difficult to implement, affecting the quality of the gyroscope, and affecting the test efficiency of the gyroscope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

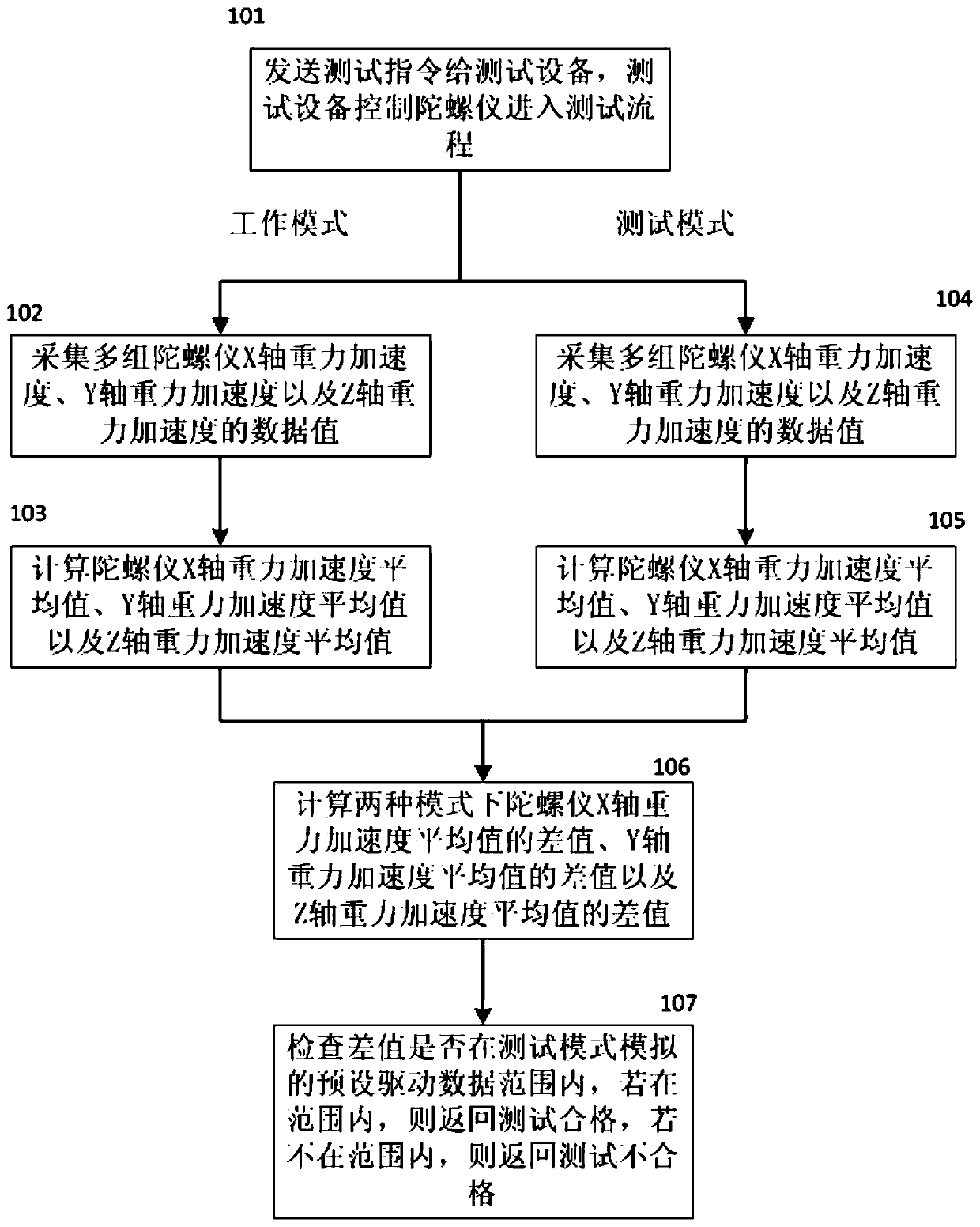

[0021] The gyroscope testing system of the present invention includes a host computer and testing equipment, the testing equipment at least includes a control module, the host computer is connected to the control module in the testing equipment, and the control module is connected to the gyroscope;

[0022] The host computer is used to send test instructions to the test equipment, and receive test results returned by the control module;

[0023] The control module is used to control the gyroscope to collect a set of data values of the gyroscope's X-axis gravity acceleration, Y-axis gravity acceleration and Z-axis gravity acceleration in the normal working mode and the test mode respectively, and calculate the corresponding values in the two modes. The difference of the X-axis gravity acceleration, the Y-axis gravity acceleration difference and the Z-axis gravity acceleration difference, check whether the difference is within the preset driving data range simulated by the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com