Verification method and device for vertical installation reliability of double-sided assembly

A technology for vertically installing and verifying devices, which is applied in the direction of measuring devices, electrical components, photovoltaic power generation, etc., and can solve problems such as inability to detect wind pressure data, surface deformation data and power generation data, and complicated installation and detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in detail below.

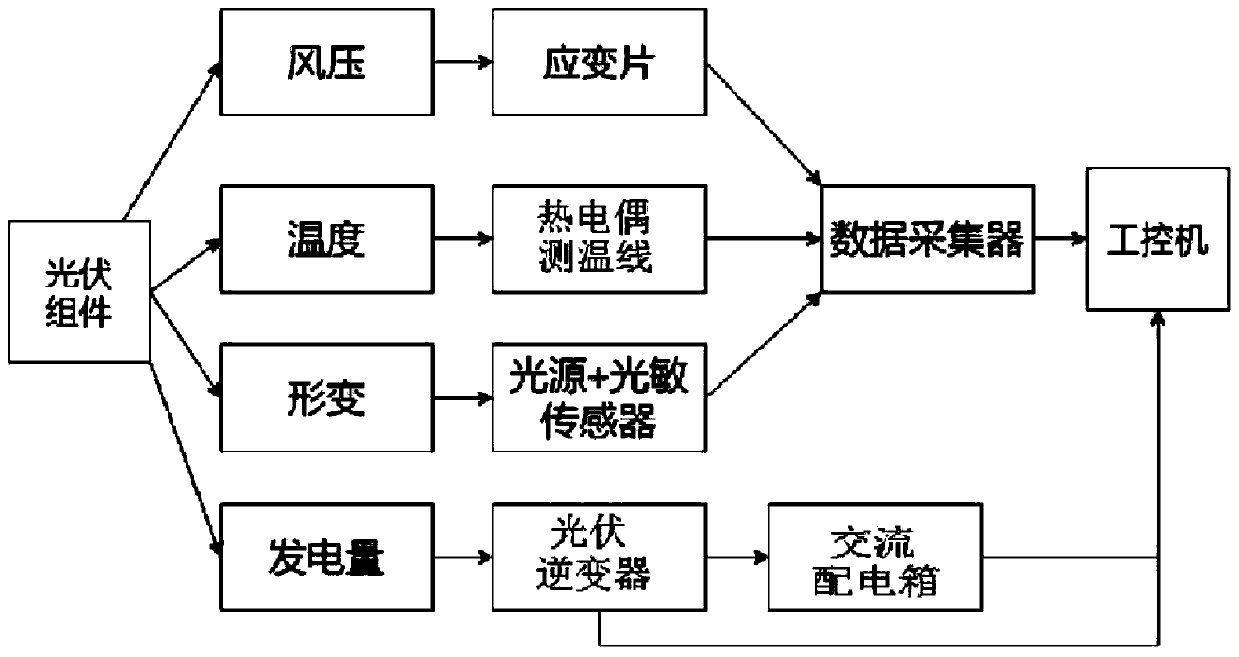

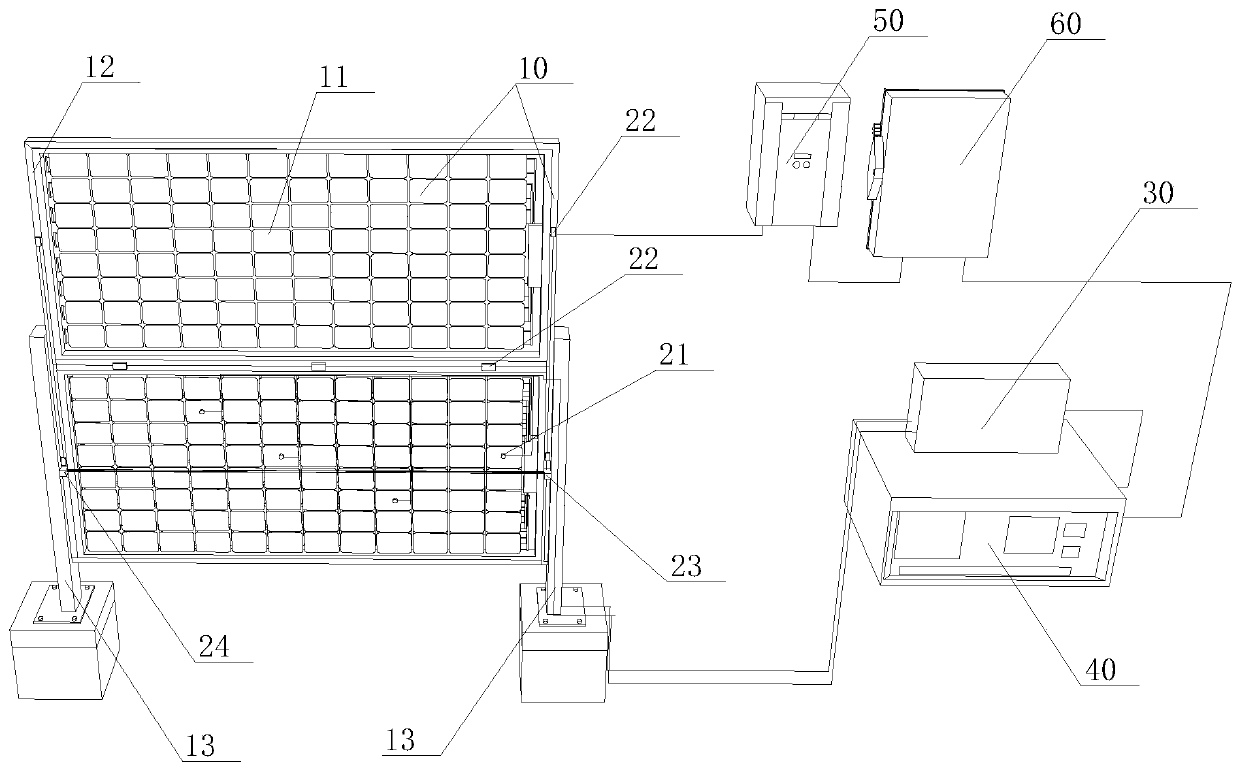

[0042] see Figure 1 to Figure 6 As shown, a method for verifying the reliability of vertical installation of double-sided modules provided by the present invention includes the following steps:

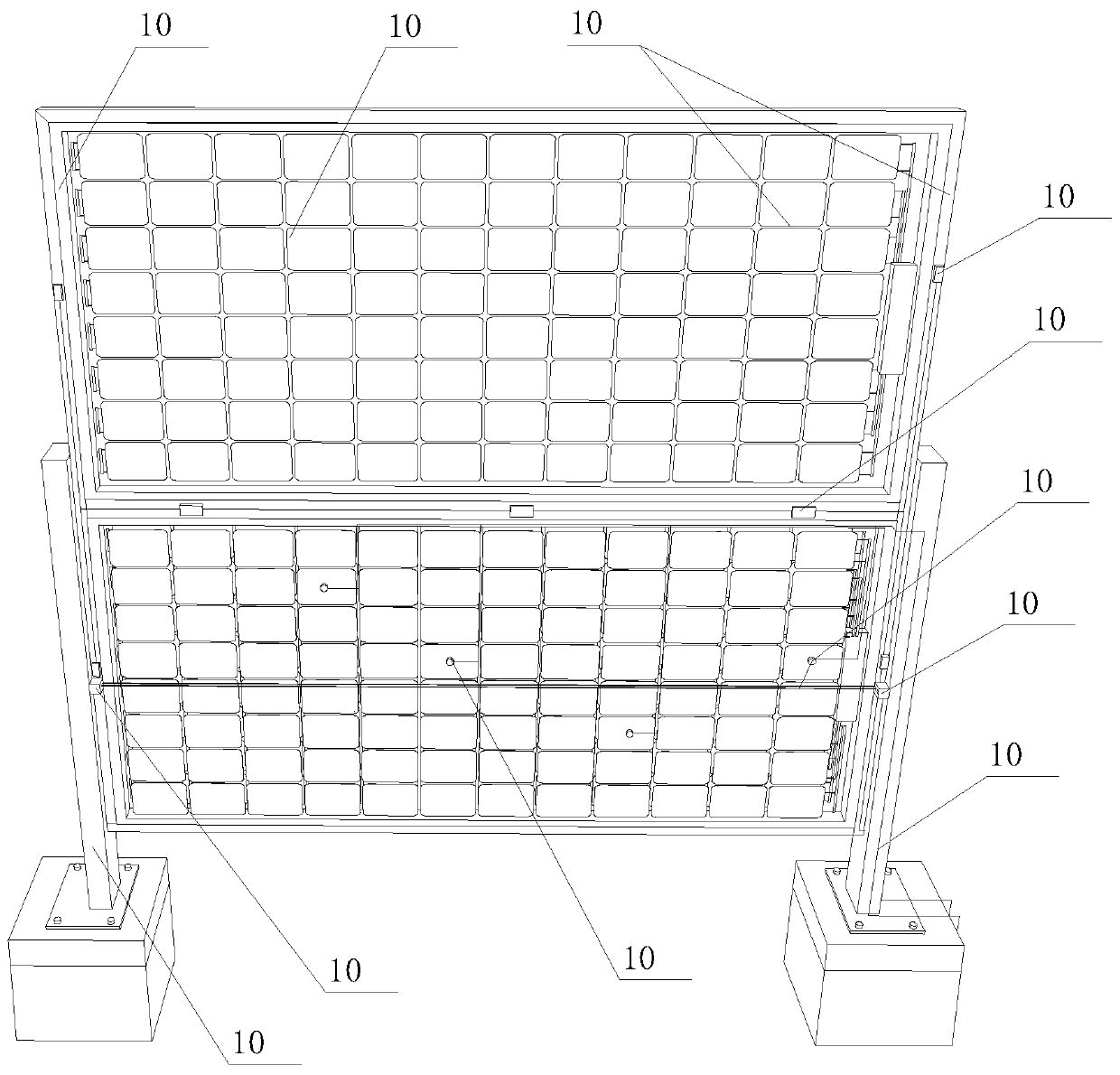

[0043] (1) On the vertically installed double-sided module 10, a double-sided module vertical installation reliability verification device is set, and the verification device includes a strain gauge 22, a photosensitive sensor 23, a light source 24, a thermocouple temperature measuring line 21, a data collector 30, The industrial computer 40, the photovoltaic inverter 50, the AC distribution box 60, the double-sided module 10 includes a photovoltaic module 11 and a module installation frame 12, and the photovoltaic module 11 is installed on two columns 13 through the module installation frame 12;

[0044] (2) Paste the two electric cores at one end of the thermocouple temperature measuring wire 21 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com