A steel ladle insulation hoisting sling

A ladle and spreader technology, which is applied in the manufacture of tools, transportation and packaging, and load hanging components, etc., can solve problems such as heat loss of molten steel, deformation and deterioration of crane hooks and wire ropes due to heat, to ensure equipment safety and avoid heat Effect of heat loss and improvement of working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following specific embodiments will further clarify the present invention. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

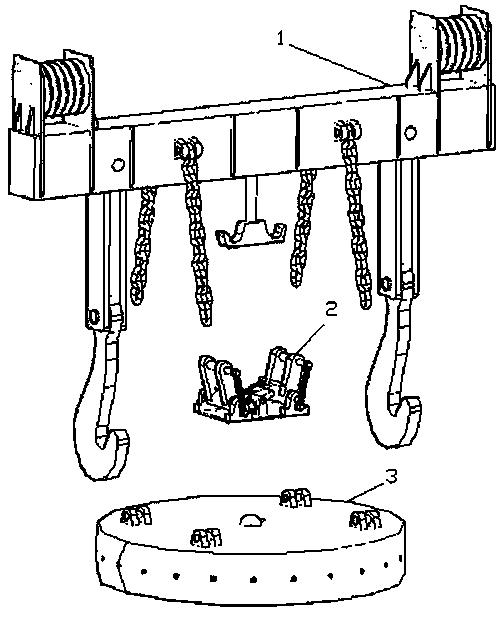

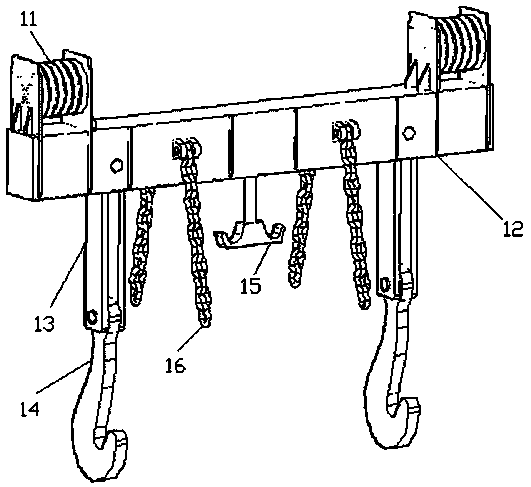

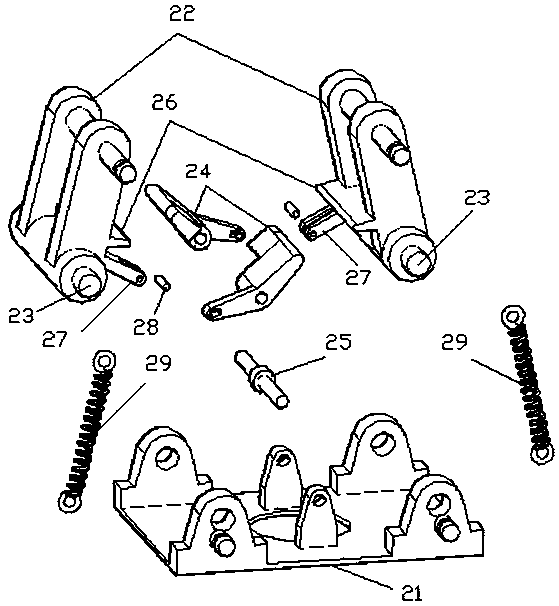

[0028] Such as figure 1 As shown, the ladle heat preservation lifting sling of this embodiment includes a hook body 1, a cover body 3, and a shutter 2 fixedly connected to the cover body. The hook body is provided with a hook body for lifting the The sub-hook 15 of the shutter, the shutter includes a base 21 connected with the cover body, the base is provided with shaft sleeves on both sides, and each of the shaft sleeves is connected by a shaft 23 There are swing arms 22. The inside of each swing arm is welded with a closing block 26 and a rocker arm 27. The lower part of the two opening blocks 24 is installed in a shaft sleeve in the middle of the base through a shaft 25. The upper ends of the stoppers are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com