Device and method for testing fracture toughness of solid-ice interface of coating layer material surface under large-area icing condition

A technology for icing conditions and fracture toughness, which is applied in measuring devices, analyzing materials, using mechanical devices, etc., to achieve the effect of simple operation, simple structure and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

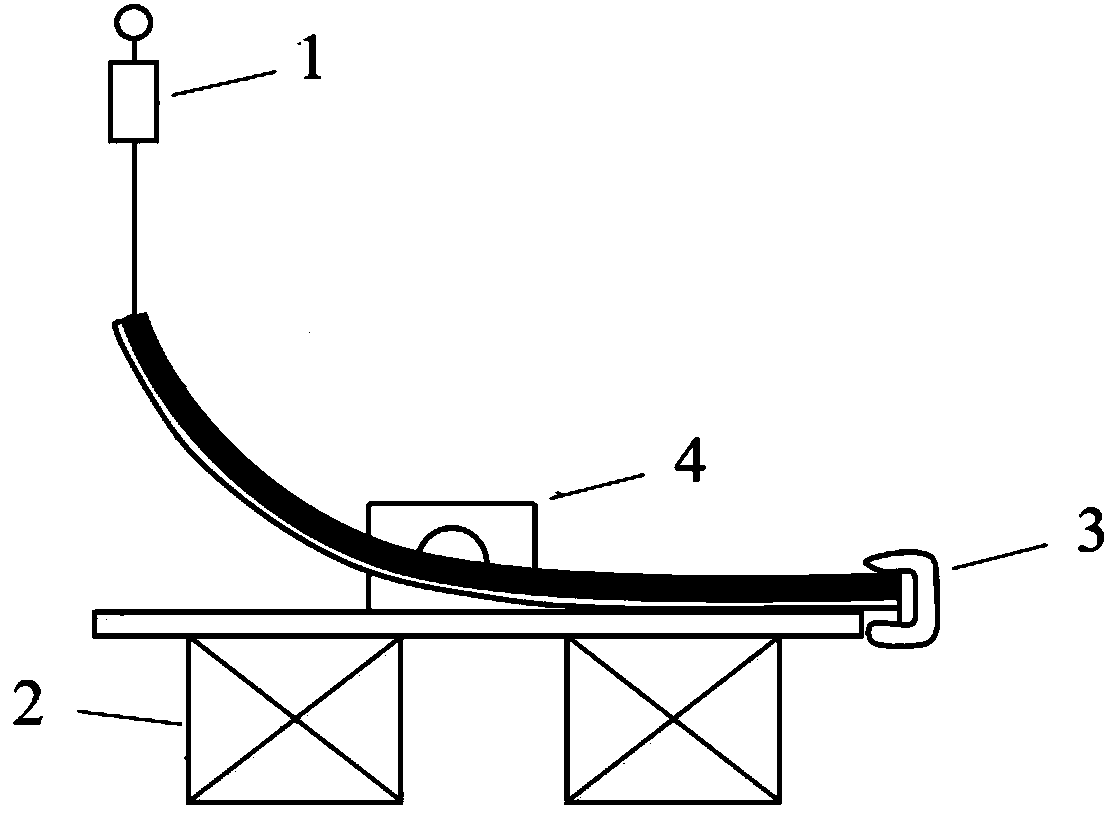

[0032] Such as figure 1 As shown, a test device for the fracture toughness of the solid-ice interface under the condition of large-area icing on the coating surface, including: a dynamometer 1, a laboratory test bench 2, a clamping device 3, and a high-speed microscopic camera 4; The laboratory test bench 2 is used to place the frozen coating sample horizontally, the clamping device 3 is used to fix the frozen coating sample, and the dynamometer 1 is used to connect the frozen coating sample. The microscope camera 4 is used to observe the fracture behavior between the coating sample surface and the ice layer.

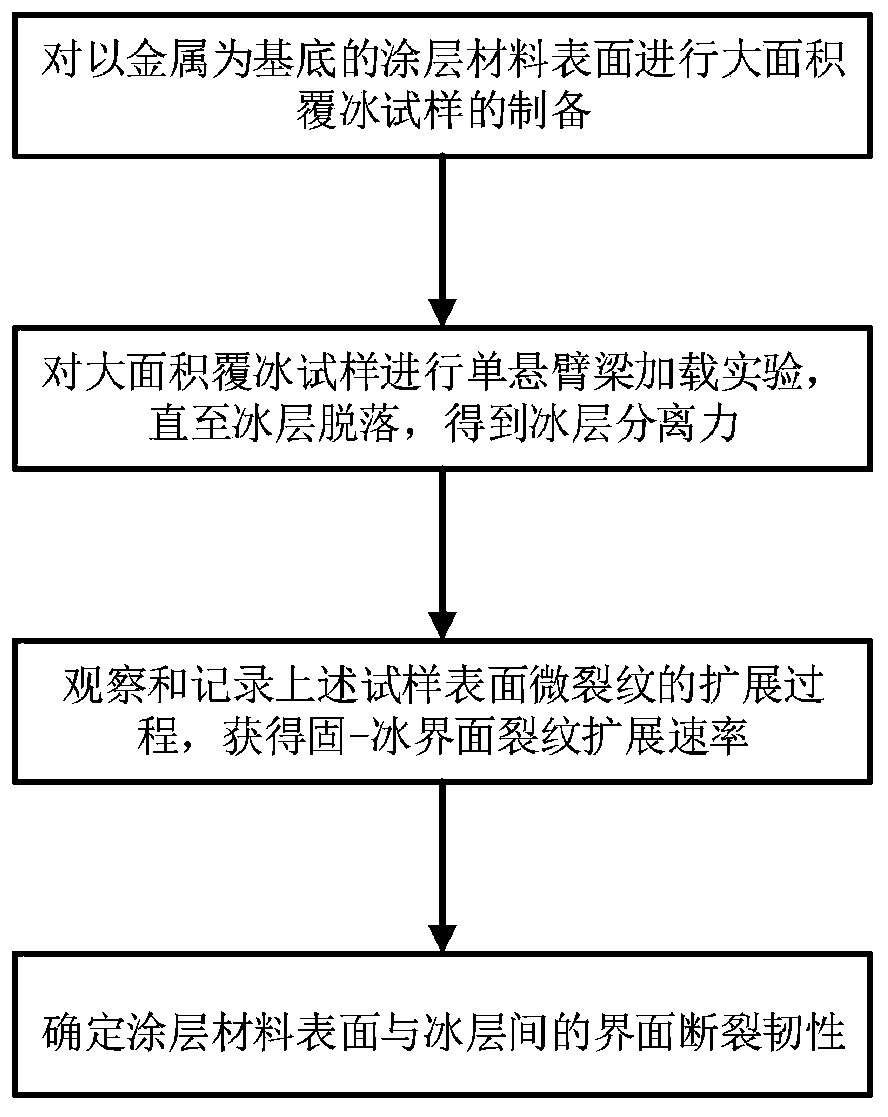

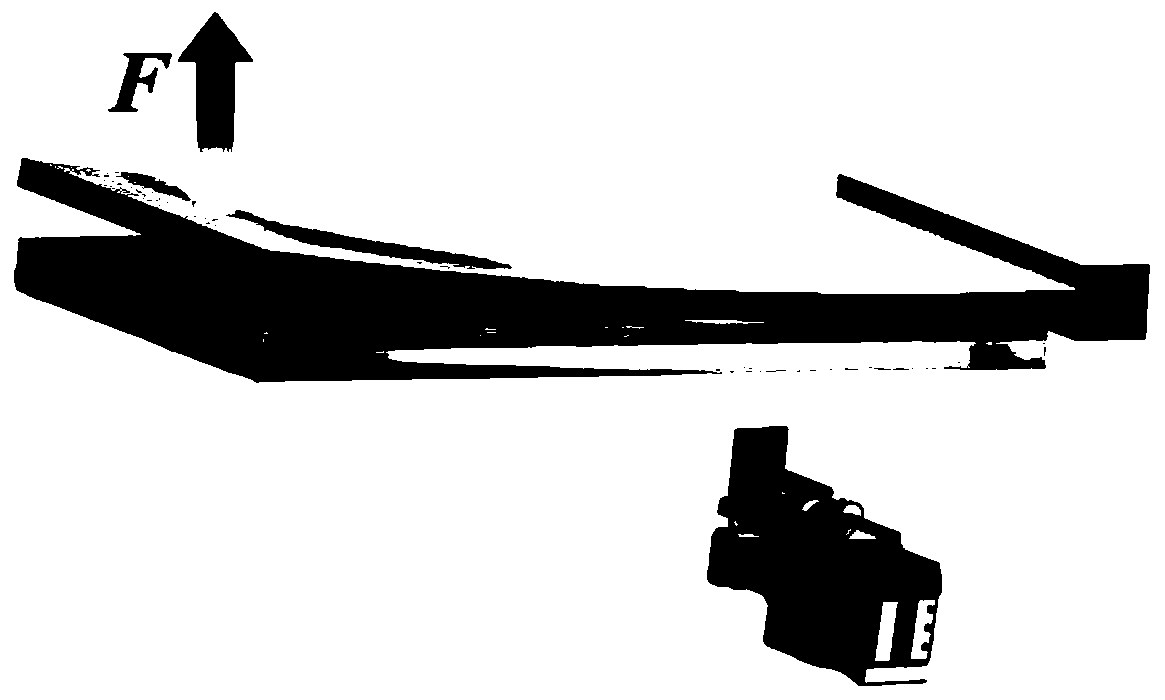

[0033] Such as figure 2 , 3 As shown, the test method for the fracture toughness of the solid-ice interface under the large-area icing condition of the coating surface is carried out by using the aforementioned test device for the fracture toughness of the solid-ice interface under the large-area icing condition on the coating surface, comprising the following steps:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com