Valve sleeve inner conical surface taper angle deviation precision design and grinding amount detection method

A precision design and detection method technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the lack of theoretical basis, the inability to be intuitively visible in inner cone surface grinding, and the absence of grinding amount detection Control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

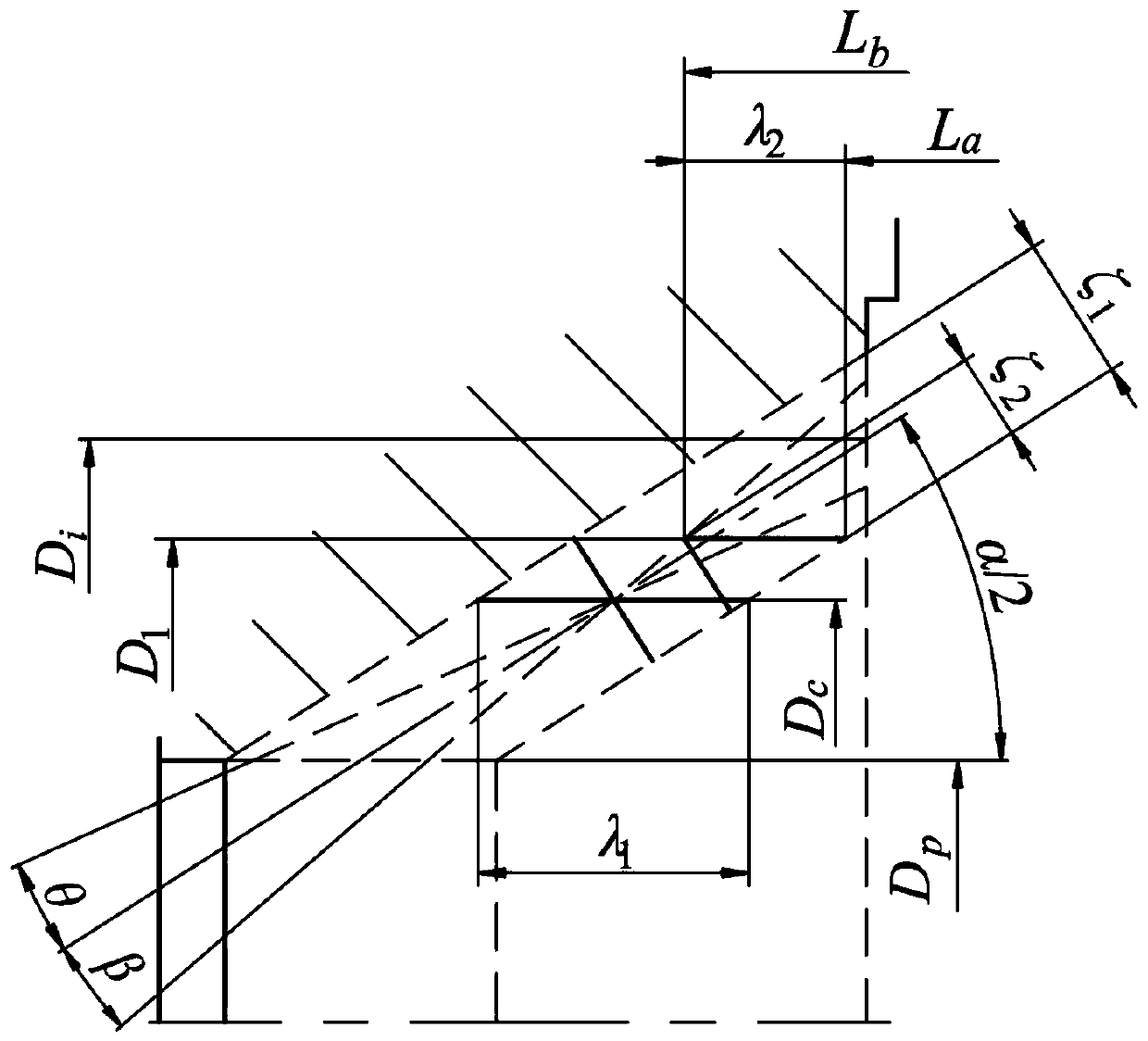

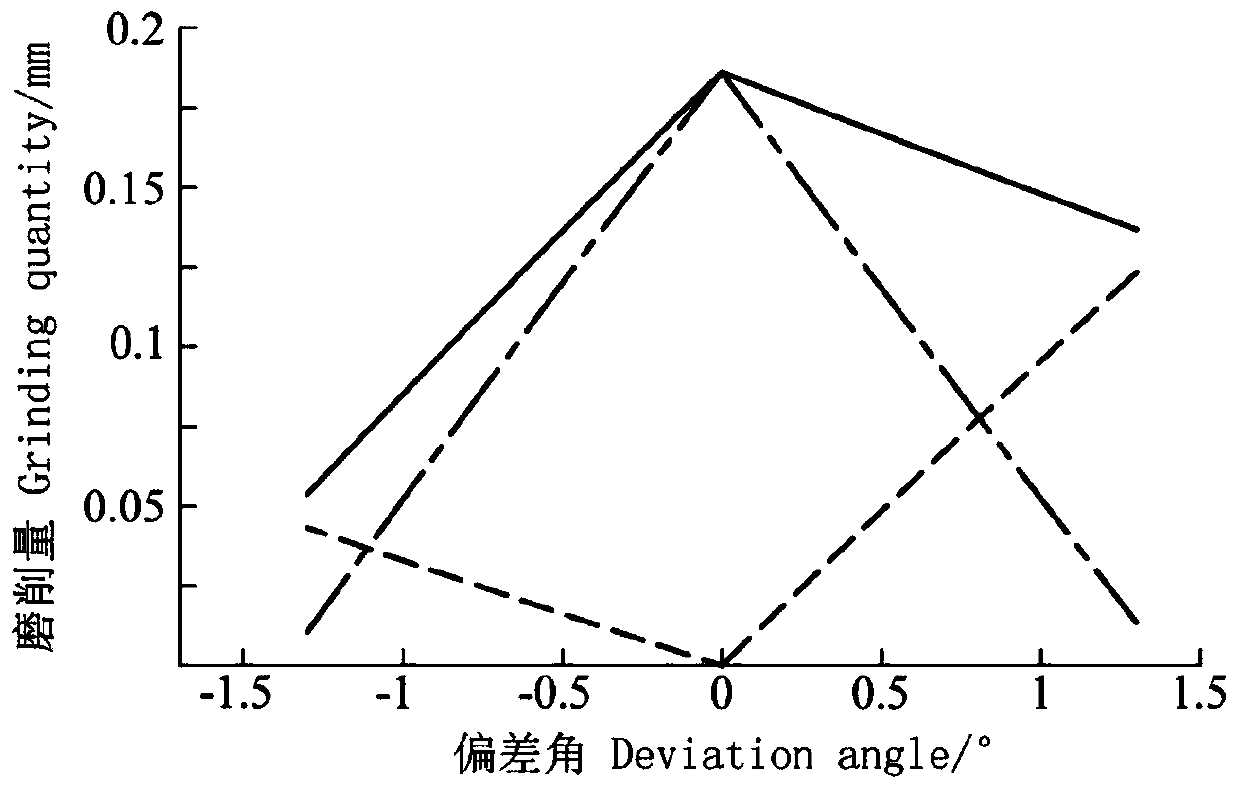

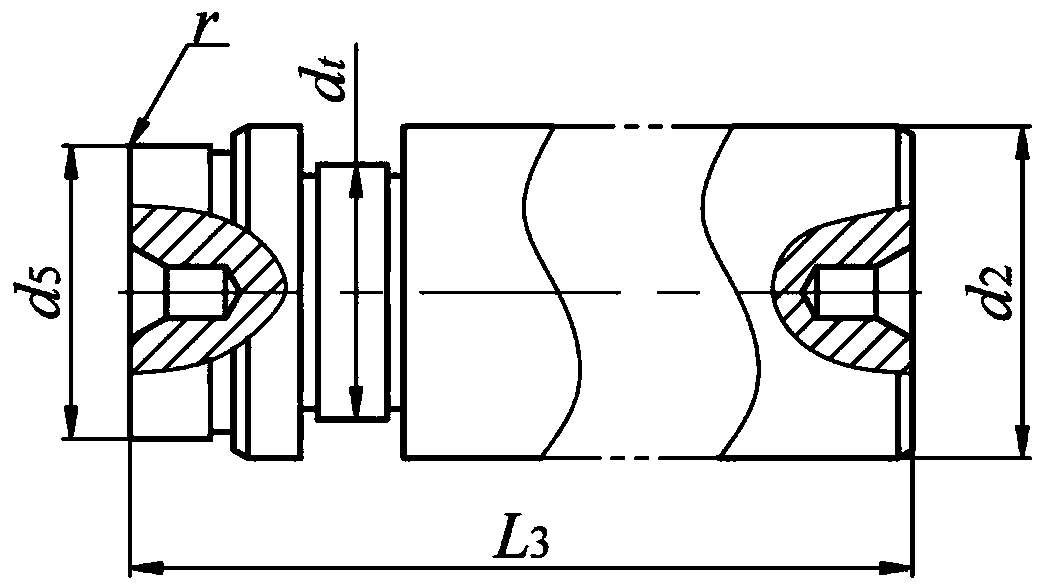

[0131] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the present invention will be further elaborated below in conjunction with specific drawings.

[0132] The precision design of the cone angle deviation of the inner cone surface of the valve sleeve and the detection method of the grinding amount, the specific steps are as follows:

[0133] 1) Determine the factors that affect the accuracy of the cone angle of the inner cone surface of the valve sleeve

[0134] By analyzing the assembly relationship and operation mode of the valve sleeve and spool structure, it is determined that the factors affecting the accuracy of the cone angle of the valve sleeve are ① static and dynamic characteristics of the relief valve, ② oil filling cracking pressure, ③ sealing and based on specific manufacturing service life of the process;

[0135] ①The static and dynamic characteristics of the relief valve require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com