An automatic monitoring and control device for steel strand wire width

An automatic monitoring and control equipment technology, applied in the direction of mechanical width measurement, measuring devices, mechanical measuring devices, etc., can solve the problems of steel strand production quality reduction, negligent inability to steel strand, accurate detection, etc., to improve practicability and Effects of reliability, energy and time saving, and simplification of detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

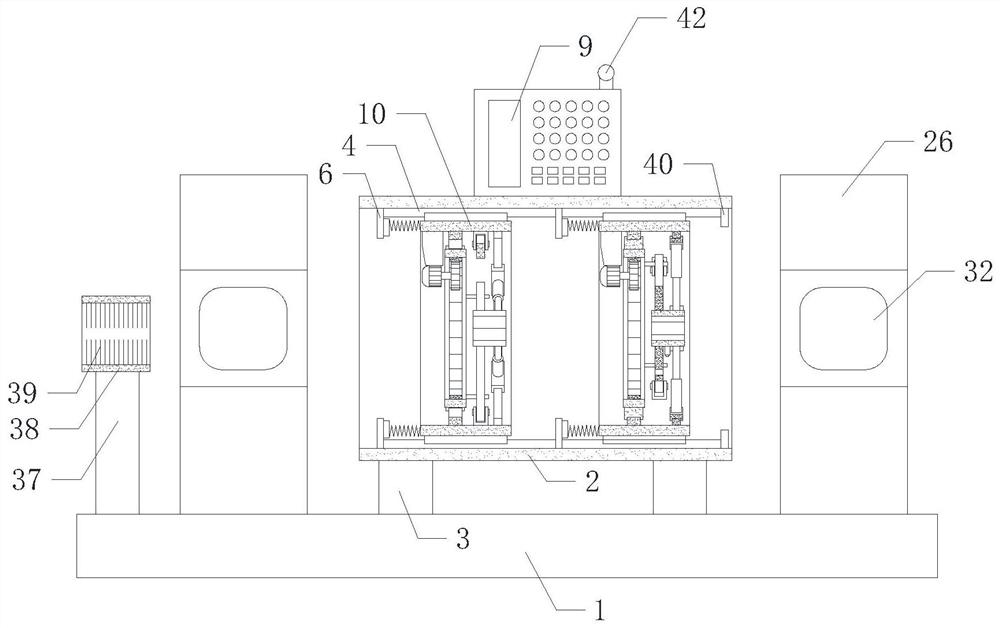

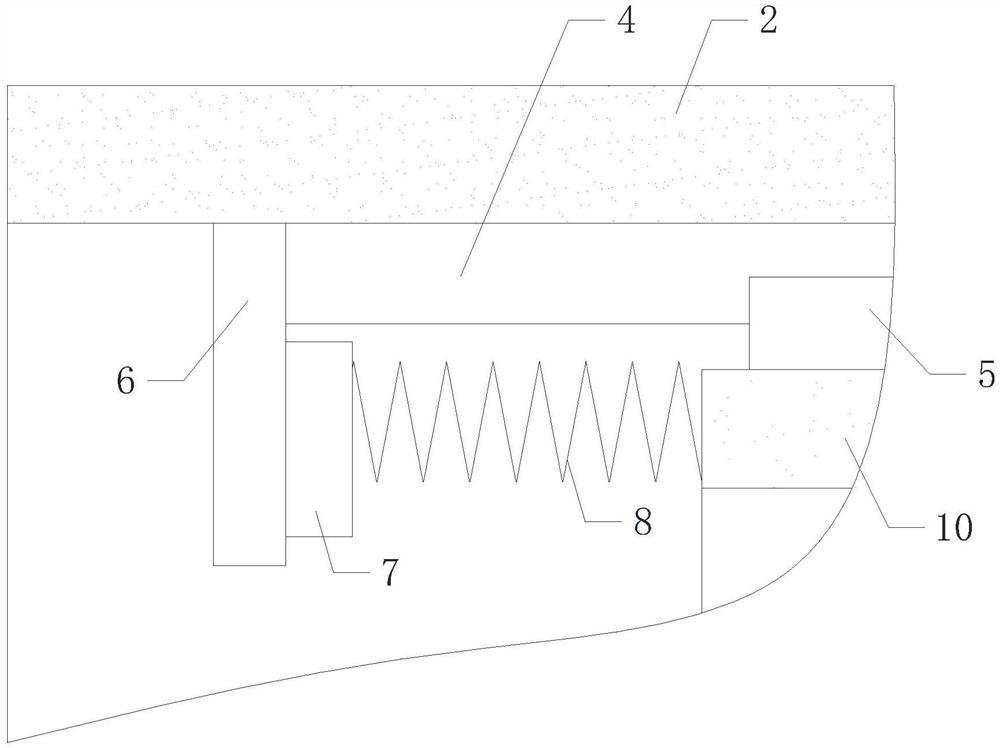

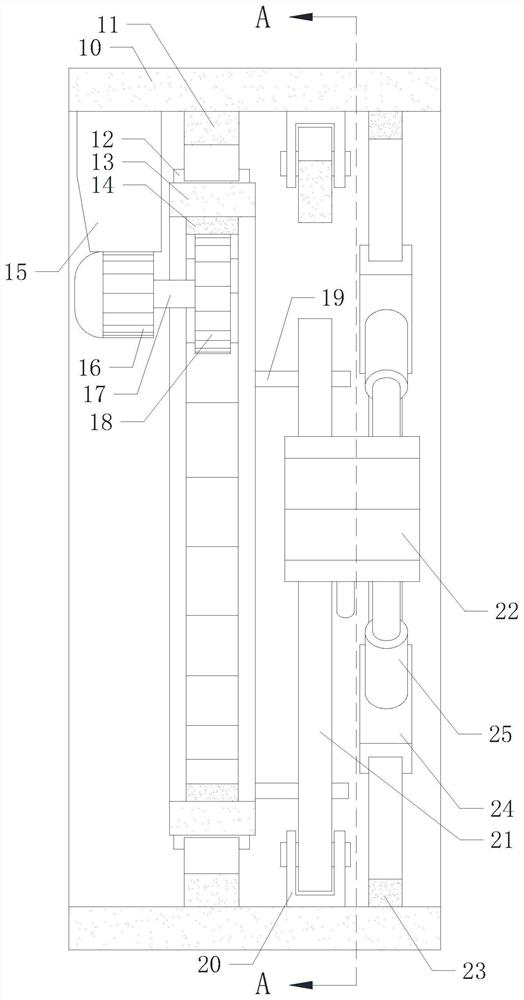

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0023] Such as Figure 1 to Figure 7 As shown, a steel strand wire width automatic monitoring and control device of the present invention, when it is working, passes the twisted steel strand through two sets of conveying devices, threading sleeve 2 and two sets of wire width limiting devices and It is transmitted to the left, and the inner walls of the two sets of line width limiting devices are close to the outer walls of the steel strands. If there is an enlarged position, the steel strand stranding fails. When the position where the line width becomes larger is transmitted to the left on the equipment to the two sets of line width limiting devices, the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com