Electric storage device based on small organic molecule dye and preparation method of electric storage device

A small molecule, electrical storage technology, applied in the fields of electrical solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of complex preparation process, poor environmental and high temperature stability, etc., and achieve simple preparation method, good environment and high temperature. Stable, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

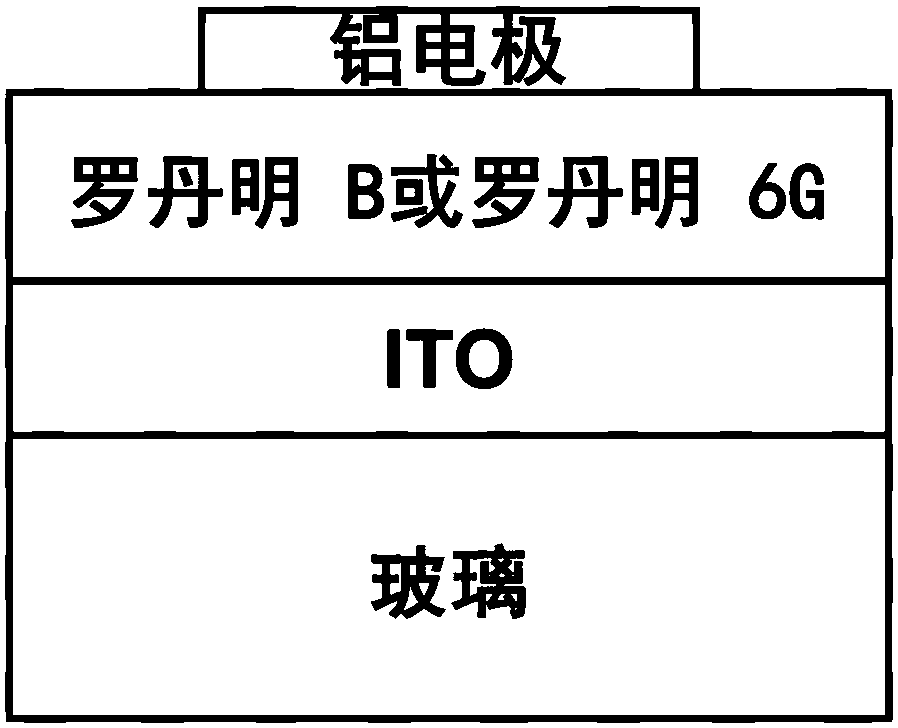

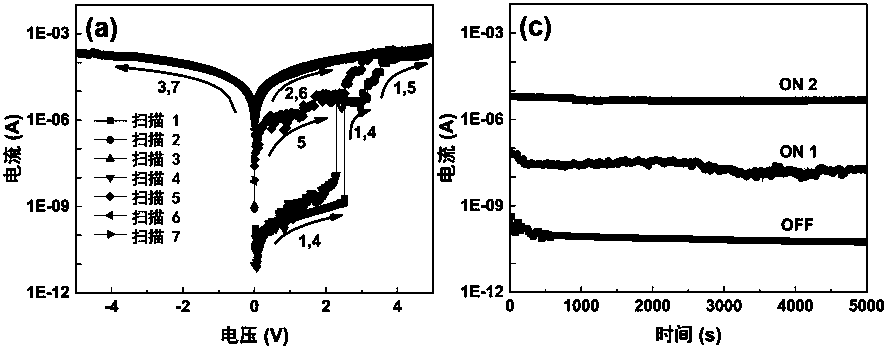

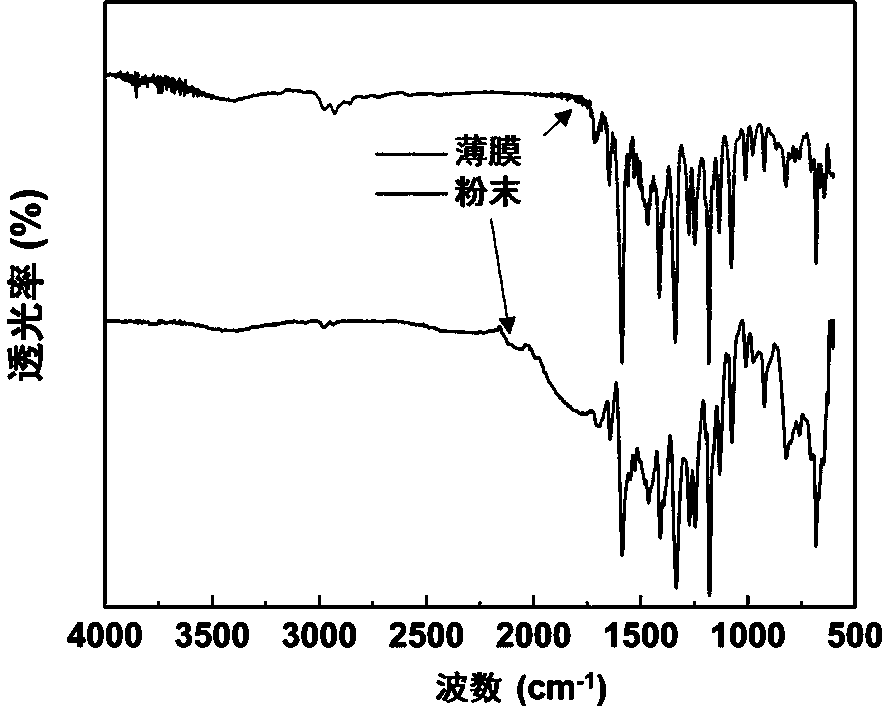

[0032] electrical storage devices such as figure 1 As shown, the device is basically divided into three layers, which are composed of an ITO glass substrate layer, an organic thin film layer and an aluminum electrode layer from bottom to top. The specific steps of the preparation method are as follows:

[0033] 1. In an ultrasonic cleaner, clean the ITO glass substrate with deionized water, acetone, and absolute ethanol in sequence;

[0034] 2. Dissolve 8 mg of rhodamine B in 1 mL of absolute ethanol to prepare rhodamine B absolute ethanol solution;

[0035] 3. Spin-coat the rhodamine B absolute ethanol solution onto the ITO glass substrate by spin-coating method in the glove box to form an organic thin film layer with a thickness of 47 nm, and then dry it in the glove box for 8 h; the spin-coating conditions are as follows : Low speed (500 r / min) for 5 s, then high speed (2000 r / min) for 20 s;

[0036] 4. Evaporate the aluminum electrode on the organic film layer until the ...

Embodiment 2

[0042] A method for preparing an electric storage device, the specific steps are as follows:

[0043] 1. In an ultrasonic cleaner, clean the ITO glass substrate with deionized water, acetone, and absolute ethanol in sequence;

[0044] 2. Add 4 mg of rhodamine 123 to 1 mL of absolute ethanol to prepare a solution, and then spin-coat it on an ITO glass substrate by spin coating in a glove box to form an organic film layer with a thickness of 41 nm, and then dry it in a glove box for 8 h; spin coating conditions are as follows: low speed (500 r / min) for 5 s, then high speed (2000 r / min) for 20 s;

[0045] 3. Evaporate the aluminum electrode on the organic film layer until the thickness of the aluminum electrode reaches 150 nm, and obtain the corresponding organic electrical storage device A; the evaporation conditions are as follows: at 5×10 -4 Under Pa vacuum conditions, the evaporation rate is 2 Å / s; finally, an organic device based on organic small molecule materials is obtai...

Embodiment 3

[0047] A method for preparing an electric storage device, the specific steps are as follows:

[0048] 1. In an ultrasonic cleaner, clean the ITO glass substrate with deionized water, acetone, and absolute ethanol in sequence;

[0049]2. Dissolve 4 mg of rhodamine 6G in 1 mL of absolute ethanol to prepare rhodamine 6G absolute ethanol solution;

[0050] 3. Spin-coat rhodamine 6G absolute ethanol solution on the ITO glass substrate by spin-coating method in the glove box to form an organic film layer with a thickness of 26 nm, and then dry it in the glove box for 8 h; the spin-coating conditions are as follows : Low speed (500 r / min) for 5 s, then high speed (2000 r / min) for 20 s;

[0051] 4. Evaporate the aluminum electrode on the organic film layer until the thickness of the aluminum electrode reaches 150 nm, and obtain the corresponding organic electrical storage device A; the evaporation conditions are as follows: at 5×10 -4 Under the Pa vacuum condition, the evaporation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com