Data cabinet structure

A cabinet and data technology, which is applied in the direction of data centers, support structure installation, circuit layout on support structures, etc., can solve the problems of increasing the cost of the cabinet and the weight of the overall cabinet, not being able to effectively prevent air leakage, and not being able to combine cabinets with side doors, etc. To achieve the effect of convenient installation of PDU and bundled cables, avoid scratching the skin, and the overall appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

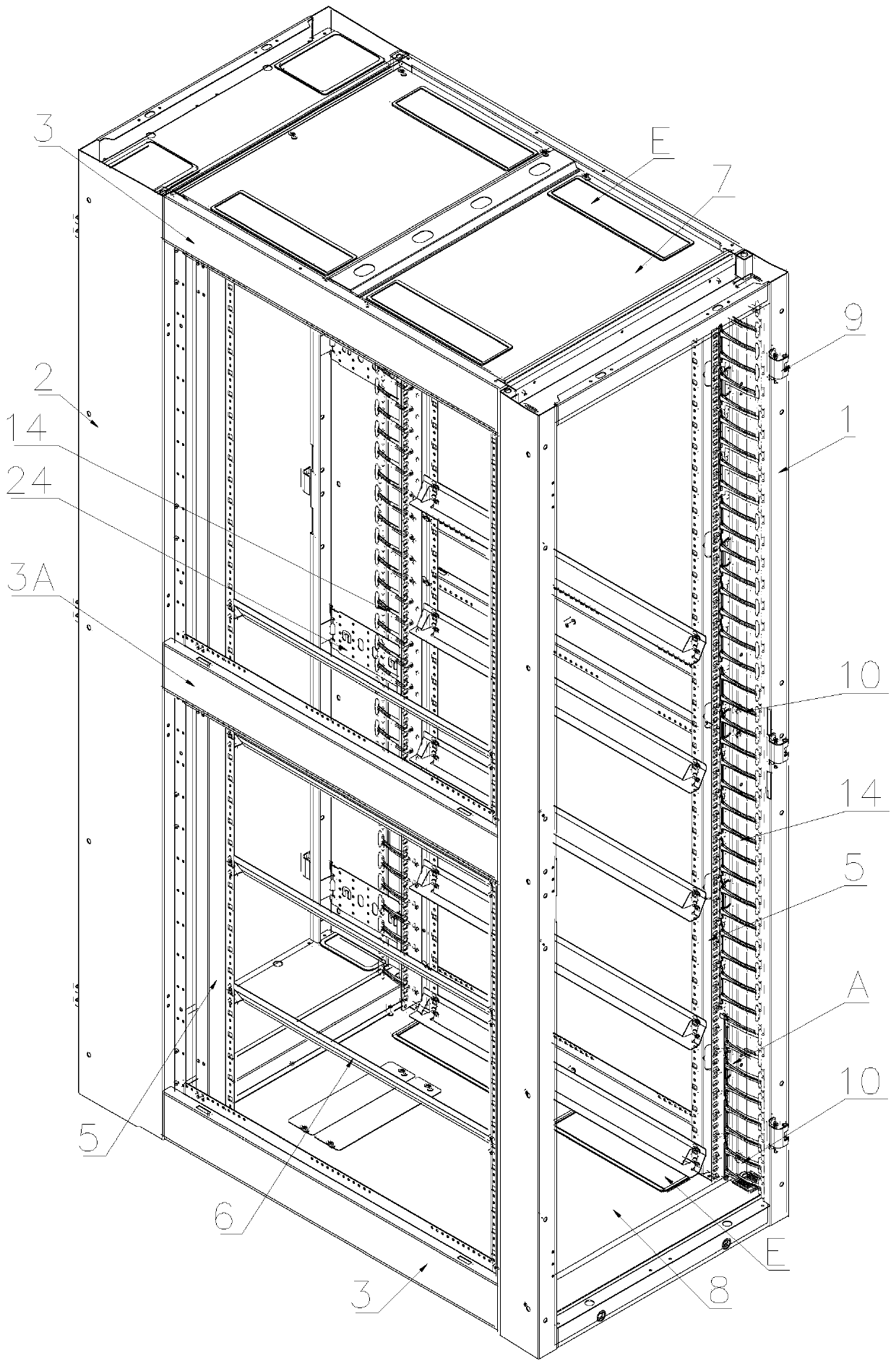

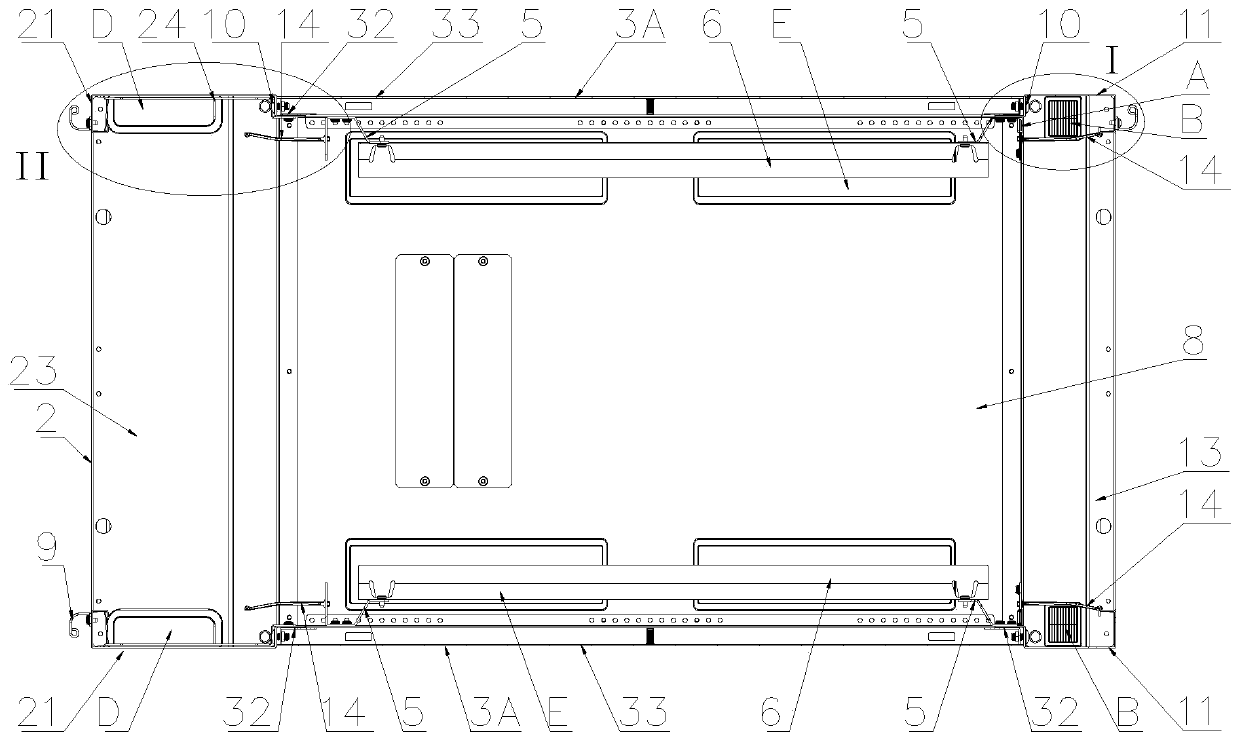

Embodiment 1

[0063] A structure of a data cabinet, which consists of a front frame ring 1, a rear frame ring 2, upper and lower beams 3, a middle beam 3A, combined screws 10, square hole strips 5, fish bones 14, cable-stayed rear support type L brackets 6, top Cover 7, bottom plate 8, top and bottom wire hole cover E, cable tie / PDU installation plate 24, sheet metal door hinge 9 for fixing the front and rear door panels, and nut plates 32 are arranged on the upper and lower beams 3 and the middle beam 3A, and the top The top wire hole 7a is provided on the cover 7, and the bottom wire hole 8a is provided on the bottom plate 8, and the square hole bar 5 is provided with a square hole bar wire hole cover A, which is characterized in that: the front frame ring 1 and the rear frame ring 2 are connected with the nut plate 32 on the upper and lower beams 3 and the middle beam 3A by the combination screw 10, the square hole bar 5 is connected and fixed with the front frame ring 1, and the fishbone...

Embodiment 2

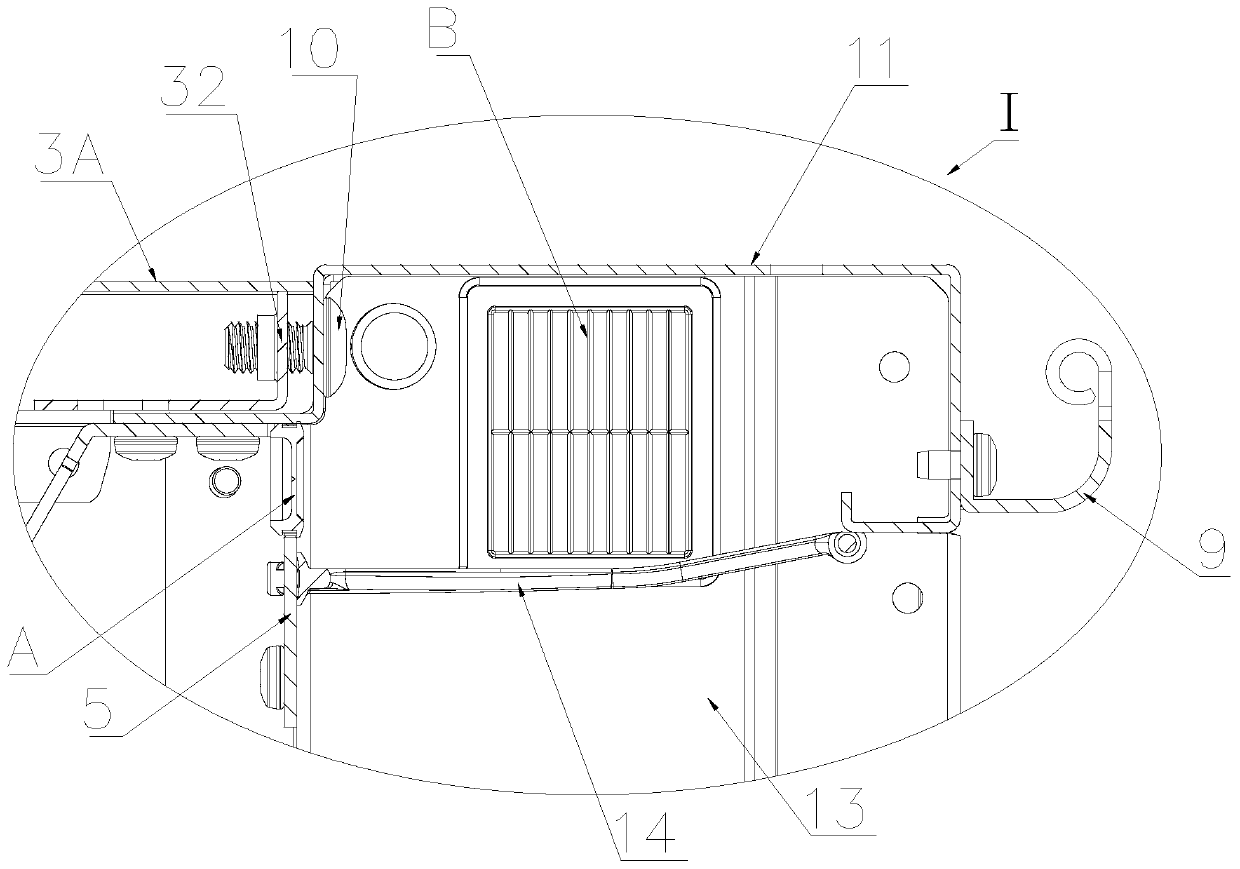

[0077] Cover plate buckle holes 11a are provided at the junction of the front column front face 114 of the front column 11 and the inner surface 115 of the front column, and the front frame ring 1 and the rear frame ring 2 are formed by combining screws 10, upper and lower beams 3 and multiple The nut plate 32 on the middle beam 3A realizes the connection, the connecting block 4 is fixed on the front frame ring 1, the square hole bar 5 is fixed on the connecting block 4, and the fishbone 14 is mated with the square hole bar 5 One end of the cover plate 15 is buckled on the front frame ring 1, and the other end is buckled on the fishbone 14 to form a cable management groove structure, and the diagonally-stayed rear support type L bracket 6 is fixed on the square hole bar 5 The top is used to support the equipment, the upper end surfaces of the front cabinet ring 1 and the rear cabinet ring 2 are fixedly installed with a top cover 7, the lower end surfaces of the front cabinet ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com