Harvester suitable for various crops

A technology for crops and harvesters, which is applied to harvesters, digging harvesters, agricultural machinery and implements, etc. It can solve the problems of high prices, inability of farmers to make backups at home, and low utilization efficiency of machines, so as to reduce human labor and facilitate concentration The effect of processing and reducing equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

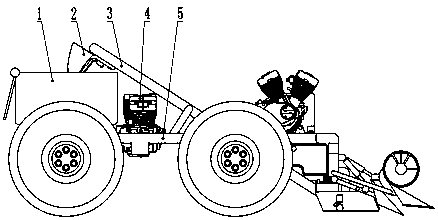

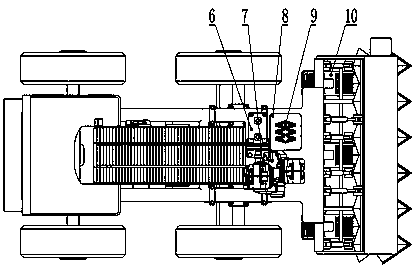

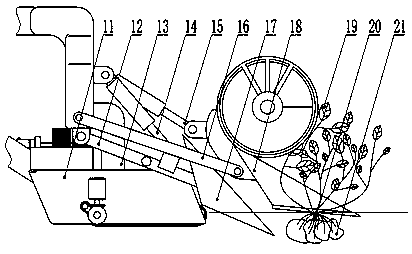

[0036] Such as Figure 1 to Figure 9 As shown, a harvester suitable for various crops, including:

[0037] Rack 5;

[0038] The harvesting device 10 is arranged on the right end of the frame 5;

[0039] The separating device 11 is arranged on the frame 5 and is located below the harvesting device 10;

[0040] storage box 1 installed on the left part of the frame 5; and

[0041] The conveying device is arranged on the frame 5, and is used to convey the crops separated by the separating device 11 into the storage box 1;

[0042] Specifically, a first engine 4, a second engine 7, a fuel tank 66, a hydraulic oil tank 8, and a hydraulic pump 6 are installed on the frame 5; wherein the first engine 4 drives the rear wheel of the frame 5 to rotate through the eleventh transmission shaft 63 , the second engine 7 provides power for the hydraulic pump 6, the fuel tank 66 provides fuel for the first engine 4 and the second engine 7, and the hydraulic pump 6 transmits hydraulic energy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com