Detection production line for seamless copper tube ultrasonic flaw detection equipment and working method of detection production line

A seamless copper tube and ultrasonic technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc., can solve the problem of prolonging the detection period of copper tubes and increasing the workload of workers , prone to rollover and other problems, to achieve the effect of improving detection efficiency and detection accuracy, improving applicability and practicability, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

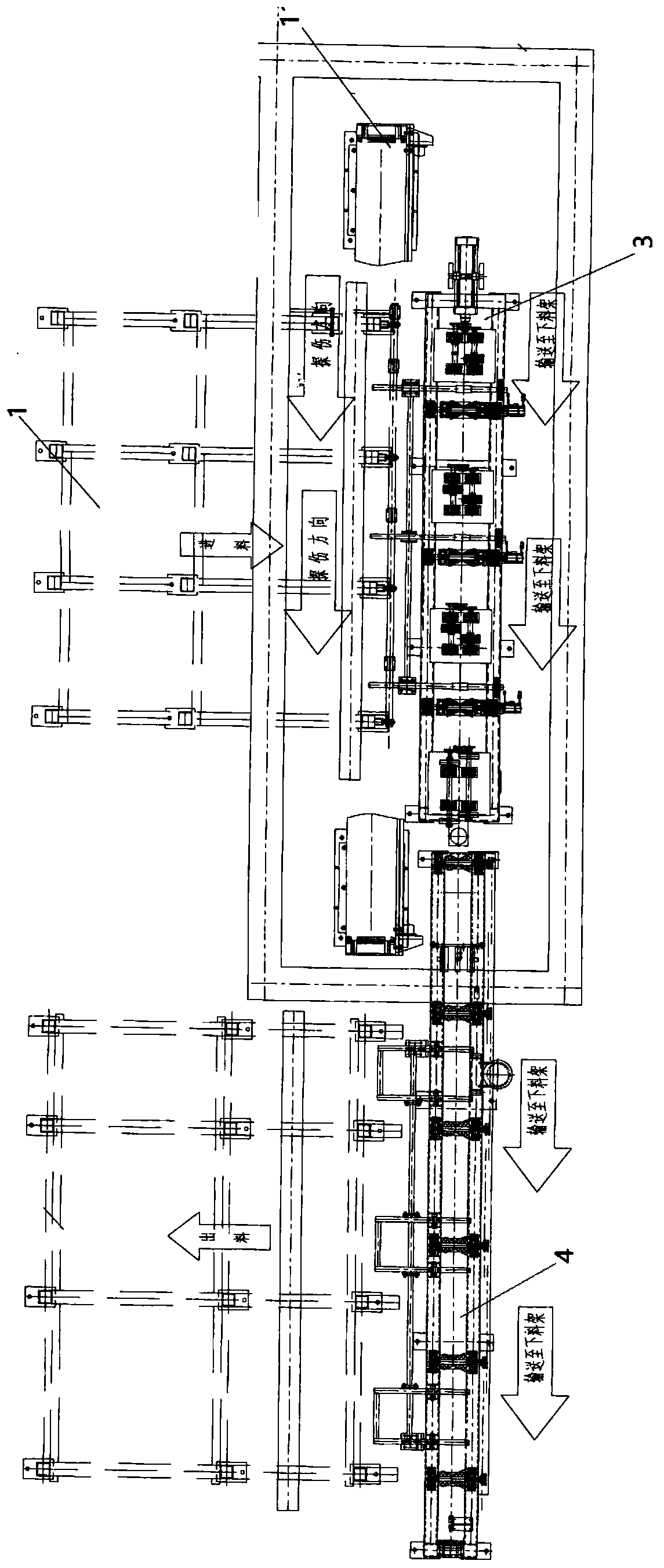

[0056] As shown in the figure, a detection production line for ultrasonic flaw detection equipment for seamless copper pipes is characterized in that it includes: a feeding device 1, a detection device 2, a feeding device 3 and a discharging device 4, and the feeding device 1 It is arranged on one side of the detection device 2, the feeding device 3 is arranged on one side of the detection device 2, and the discharge device 4 is arranged at the end of the feeding device 3;

[0057] Wherein, the detection device 2 is provided with...

Embodiment 2

[0068] As shown in the figure, a testing production line for ultrasonic flaw detection equipment for seamless copper tubes includes: a feeding device 1, a testing device 2, a feeding device 3 and a discharging device 4, and the feeding device 1 is arranged on the testing device 2, the feeding device 3 is arranged on one side of the detection device 2, and the discharging device 4 is arranged at the end of the feeding device 3;

[0069] Wherein, the detection device 2 is provided with a column beam for installing a detector, a detection trolley and a detection control device, the detection trolley is arranged on the column beam, and the two are connected in a sliding manner, the detection trolley and the detection control device connection.

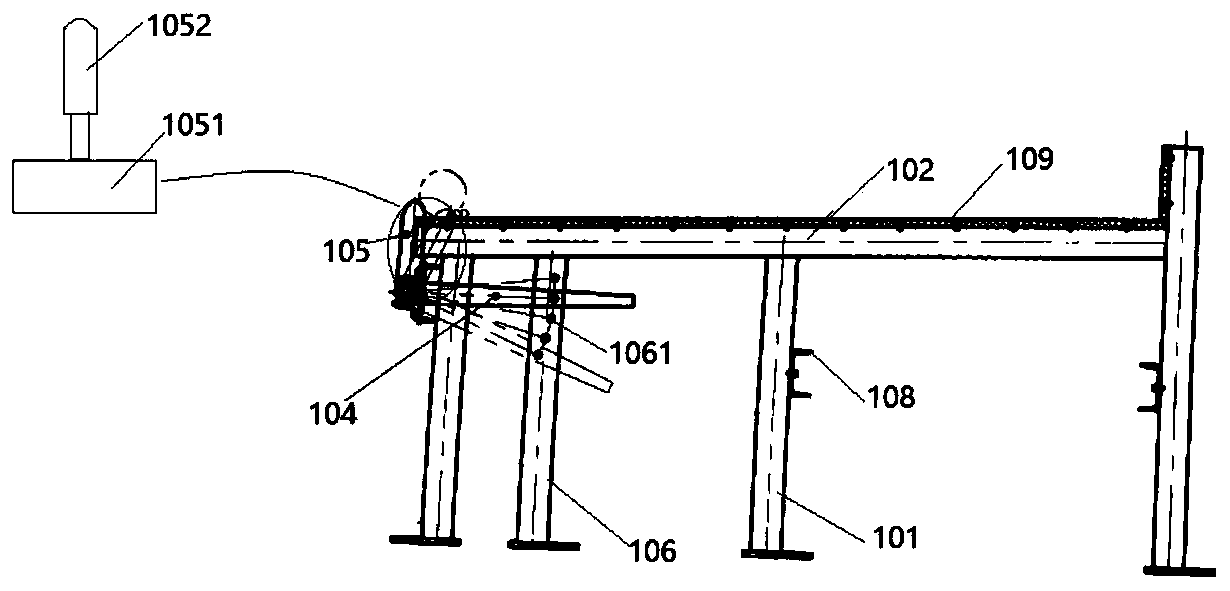

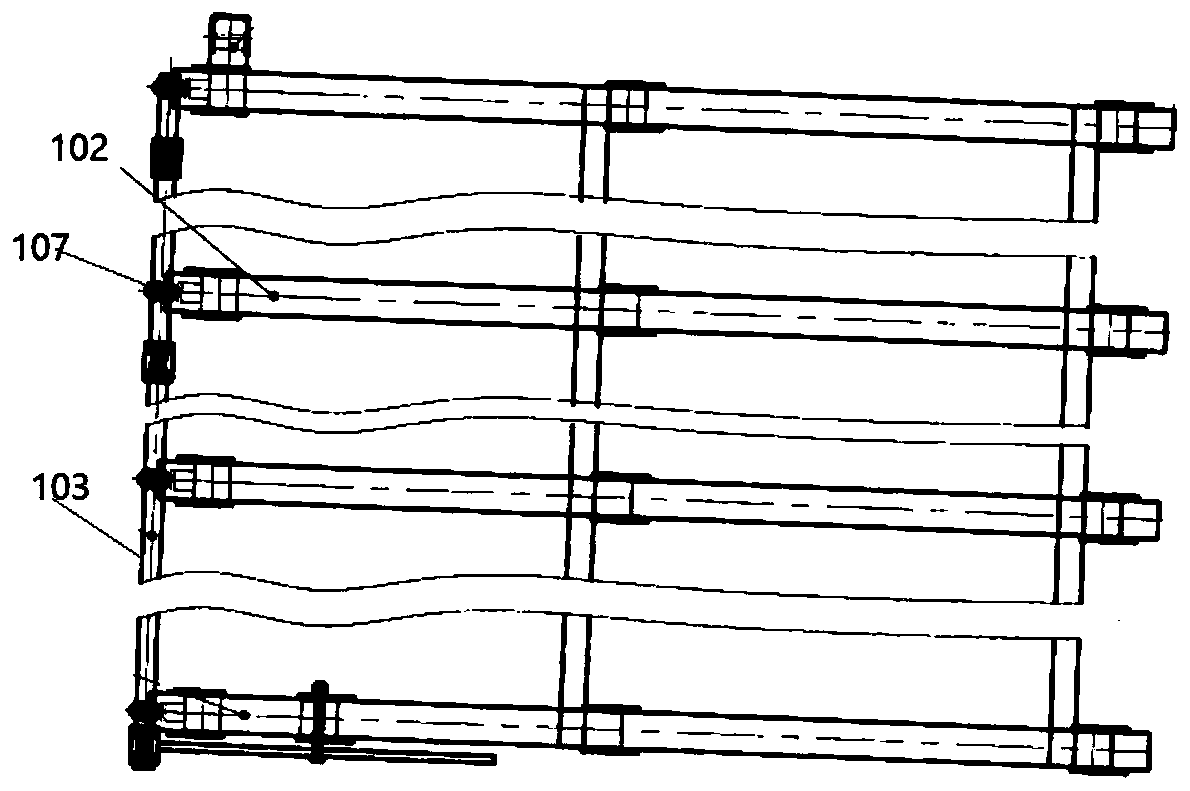

[0070] Wherein, described feeding device 1 is provided with one group of feeding columns 101, one group of feeding racks 102, feeding shaft 103, feeding rod 104 and blocking mechanism 105, and described support frame 102 is located at feed...

Embodiment 3

[0119] A detection production line for ultrasonic flaw detection equipment for seamless copper pipes described in this embodiment, its working method is as follows:

[0120] 1): First click start on the display screen control device, and then the feeding device starts feeding, that is, feeding device 1 feeds material to feeding device 3, and a tube material detection switch is set on the feeding rack 102, when the detection switch detects When the seamless copper pipe is reached, the conveying device 33 on the feeding device 3 waits for feeding, and in the process, the blocking mechanism 105 is released, and the seamless copper pipe enters the feeding device 3;

[0121] 2): When the detection switch detects that there is material, the control device will control the detection trolley to move automatically. When the detection trolley detects pipe fittings, the rotation starts, and the detection trolley continues to walk. When the detection trolley walks to the position of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com