Winding device for spinning processing

A winding device and spinning technology, which is used in transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems of trouble for operators, reduce work efficiency, and the spinning cannot be wound evenly. The effect of uniform winding of silk thread and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

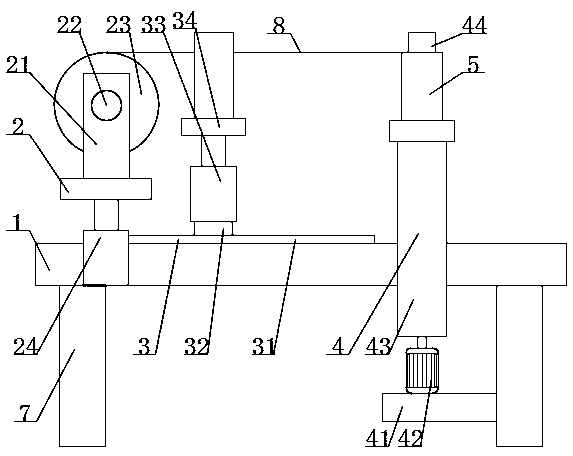

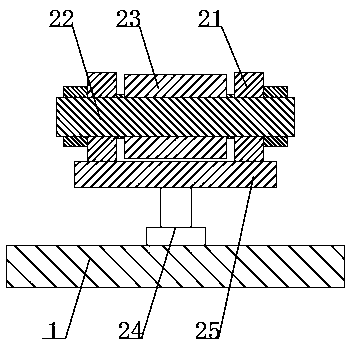

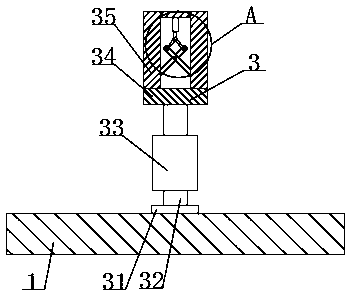

[0031] see Figure 1-2, the present invention provides a technical solution: a winding device for spinning, including a bearing platform 1, a lifting structure 2, a clamping structure 3 and a winding structure 4, and the middle part of the upper surface of the bearing platform 1 is fixed near one end A lifting structure 2 is installed, and the lifting structure 2 includes a first support plate 21, a connecting rod 22, a turntable 23, a first electric telescopic rod 24 and a support platform 25, and the middle part of the upper surface of the platform 1 is fixedly connected with a second An electric telescopic rod 24, the electric telescopic rod 24 is specifically a type of electric telescopic rod NKLA8, one end of the first electric telescopic rod 24 is fixedly connected with a support platform 25 by bolts, and the middle part of the upper surface of the support platform 25 is Both sides are fixedly connected with a first support plate 21 by bolts, and a connecting rod 22 is i...

Embodiment 2

[0033] see Figure 1-4 , the present invention provides a technical solution: a winding device for spinning, including a bearing platform 1, a lifting structure 2, a clamping structure 3 and a winding structure 4, and the middle part of the upper surface of the bearing platform 1 is fixed near one end A lifting structure 2 is installed, and the lifting structure 2 includes a first support plate 21, a connecting rod 22, a turntable 23, a first electric telescopic rod 24 and a support platform 25, and the middle part of the upper surface of the platform 1 is fixedly connected with a second An electric telescopic rod 24, the electric telescopic rod 24 is specifically a type of electric telescopic rod NKLA8, one end of the first electric telescopic rod 24 is fixedly connected with a support platform 25 by bolts, and the middle part of the upper surface of the support platform 25 is Both sides are fixedly connected with a first support plate 21 by bolts, and a connecting rod 22 is ...

Embodiment 3

[0035] see Figure 1-5 as well as Figure 7, the present invention provides a technical solution: a winding device for spinning, including a bearing platform 1, a lifting structure 2, a clamping structure 3 and a winding structure 4, and the middle part of the upper surface of the bearing platform 1 is fixed near one end A lifting structure 2 is installed, and the lifting structure 2 includes a first support plate 21, a connecting rod 22, a turntable 23, a first electric telescopic rod 24 and a support platform 25, and the middle part of the upper surface of the platform 1 is fixedly connected with a second An electric telescopic rod 24, the electric telescopic rod 24 is specifically a type of electric telescopic rod NKLA8, one end of the first electric telescopic rod 24 is fixedly connected with a support platform 25 by bolts, and the middle part of the upper surface of the support platform 25 is Both sides are fixedly connected with a first support plate 21 by bolts, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com