Method for evaluating filtering precision and efficiency of submicron liquid-solid separation system

A filtration accuracy, sub-micron technology, applied in the testing of machines/structural components, analysis of suspensions and porous materials, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

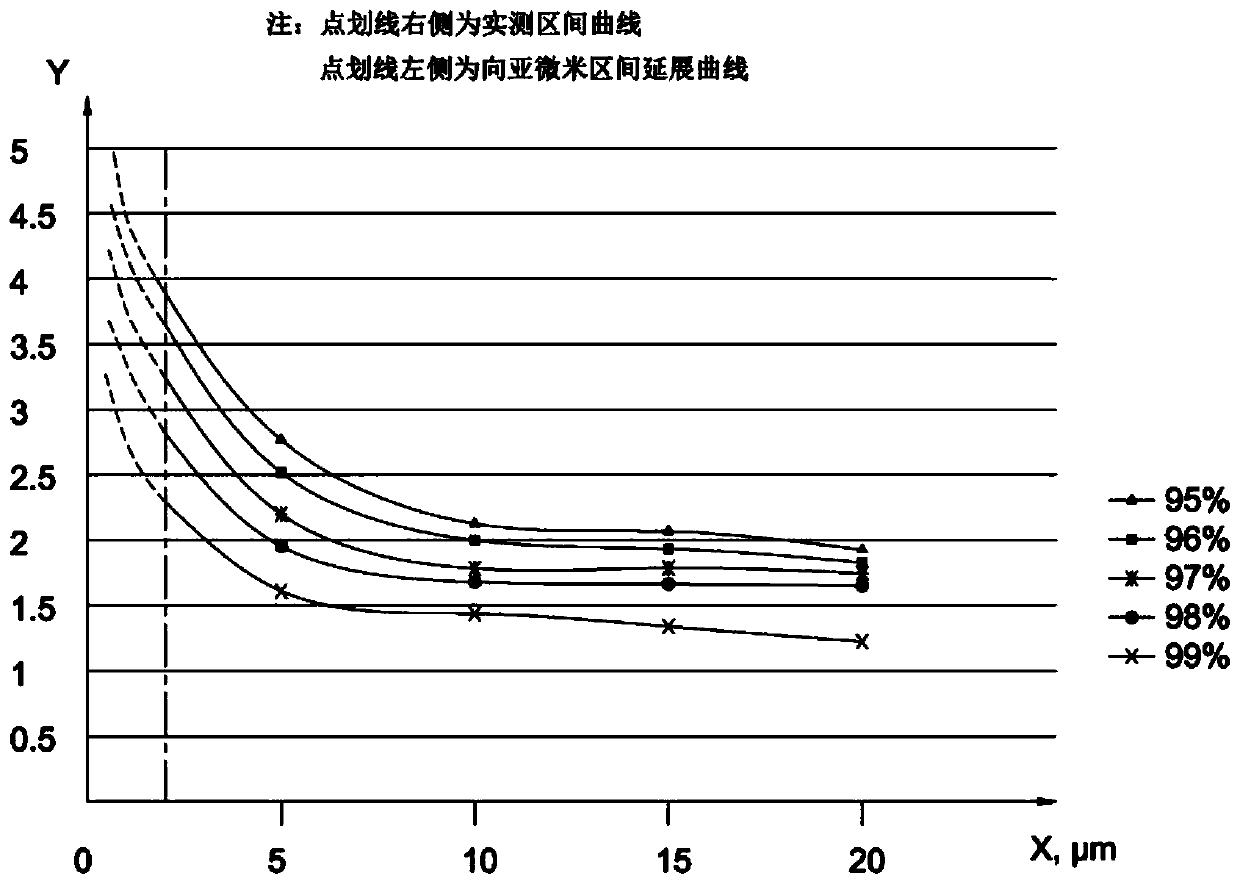

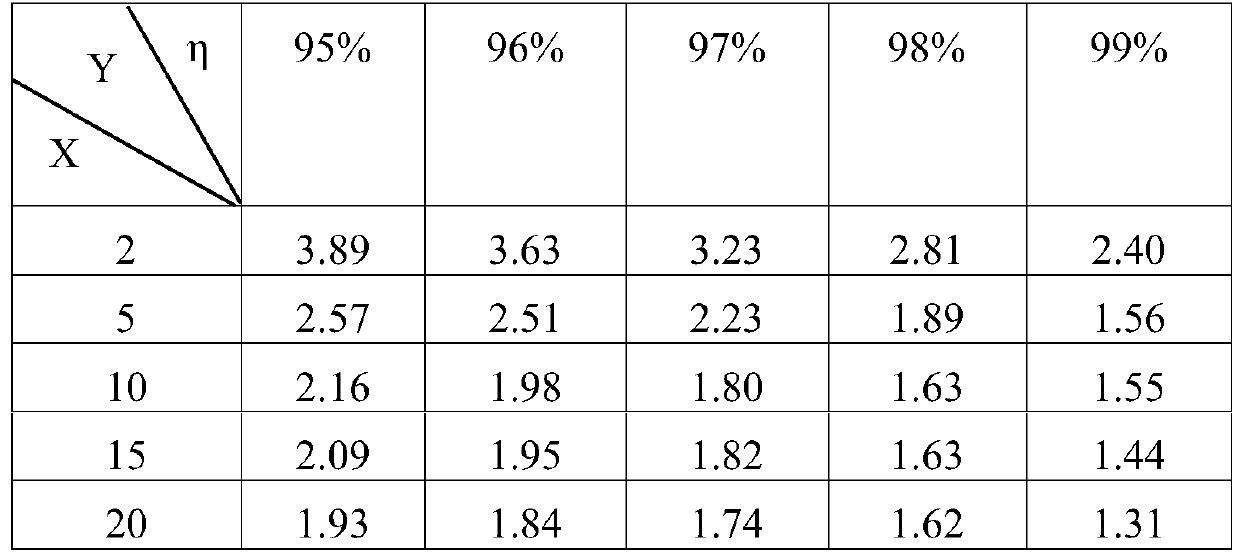

[0030] A water filter is required to filter particles with a filtration accuracy of 0.5 μm and a filtration efficiency of 95%. Based on this, it is required to test the filter element of a specified filter material (the pore size value of the filter element is measured by a pore size testing instrument D 实测 =7.23μm) can meet the requirements. Since it is difficult for the current test device to directly detect parameter information such as filtration efficiency with a filtration accuracy of 0.5 μm, the method of the present invention is used for evaluation.

[0031] Mix MTD A3 powder evenly in pure water to prepare the raw material solution required for the test, and then use the filtration performance test device to conduct the filtration test. The filtration test equipment is a routinely used testing equipment, which mainly includes a raw liquid tank, a pump, a filter, a flow meter, a differential pressure meter, pipelines and valves. The test conditions are: the test flow ...

Embodiment 2

[0045] For another test filter material of the same type as in Example 1, its pore diameter measured by a pore size tester is D 实测 = 1.15 μm, it is required to judge whether the filtration efficiency of 99% can be achieved under the filtration accuracy of 0.5 μm.

[0046] Adopt same test condition among the embodiment 1, obtain its fitting equation under 99% filtration efficiency to be Y=-2.5195E-3X3+7.7665E-2X2-0.7251X+3.5547, get X=0.5, then calculate Y= 3.21.

[0047] From Y=D / X, the theoretical pore diameter D can be obtained 理论 = 1.61 μm, which is 1.15 μm larger than the measured pore size, therefore, it is judged that the filter material can meet the requirements.

[0048] At the same time, the rationality of the filter material selection can be evaluated, because the measured pore size D 实测 =1.15μm is much smaller than the theoretical aperture D 理论 =1.61μm, therefore, it is too strict to evaluate this selection. Since the cost of the filter material with smaller po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com