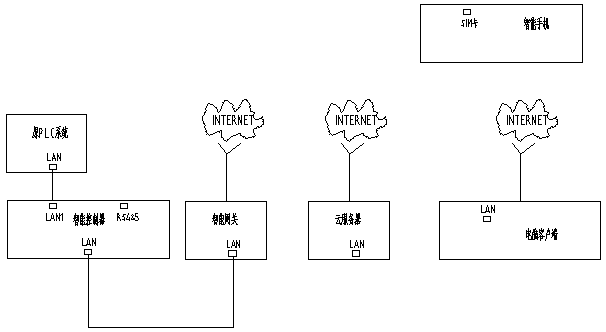

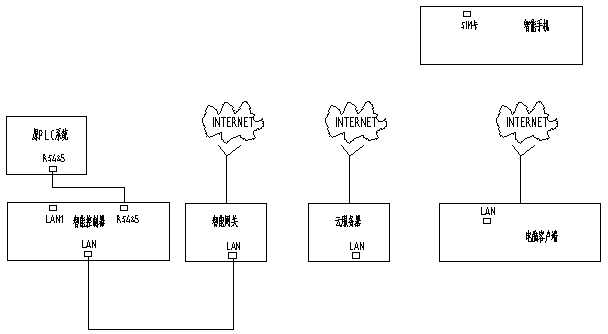

OEE remote operation and maintenance method for intelligent control system equipment

A technology of intelligent control system and intelligent controller, which is applied in general control system, control/adjustment system, program control, etc., to eliminate hidden dangers, save hardware costs, and improve operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The actual implementation of the technical solution of the present invention will be further described below according to the examples.

[0061] Take the anvil detection and alarm device of the synthetic diamond six-sided press as an example: the synthetic diamond six-sided press is a 24-hour continuous working system, and the processing time is 20-30 minutes each time. Due to the high cost of the top hammer, if the force is uneven or the quality of the top hammer is defective, cracks will appear in the top hammer during the working process, causing serious accidents and even bursting of the entire equipment.

[0062] Each top hammer of the existing synthetic diamond six-sided top press is equipped with a 4096-type P+F absolute value encoder, and each encoder is connected to the SMART200 PLC by Ethernet communication, and the curve drawing is completed through the IPC610 industrial computer. In each processing cycle, each of the six top hammers reciprocates once, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com