Jig applied to high-pressure flushing of packaged chip

A technology for high-pressure washing and chip loading, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc. It can solve the problems of lead washing deformation, overflow washing is not clean, easy to damage leads, etc., and achieve the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

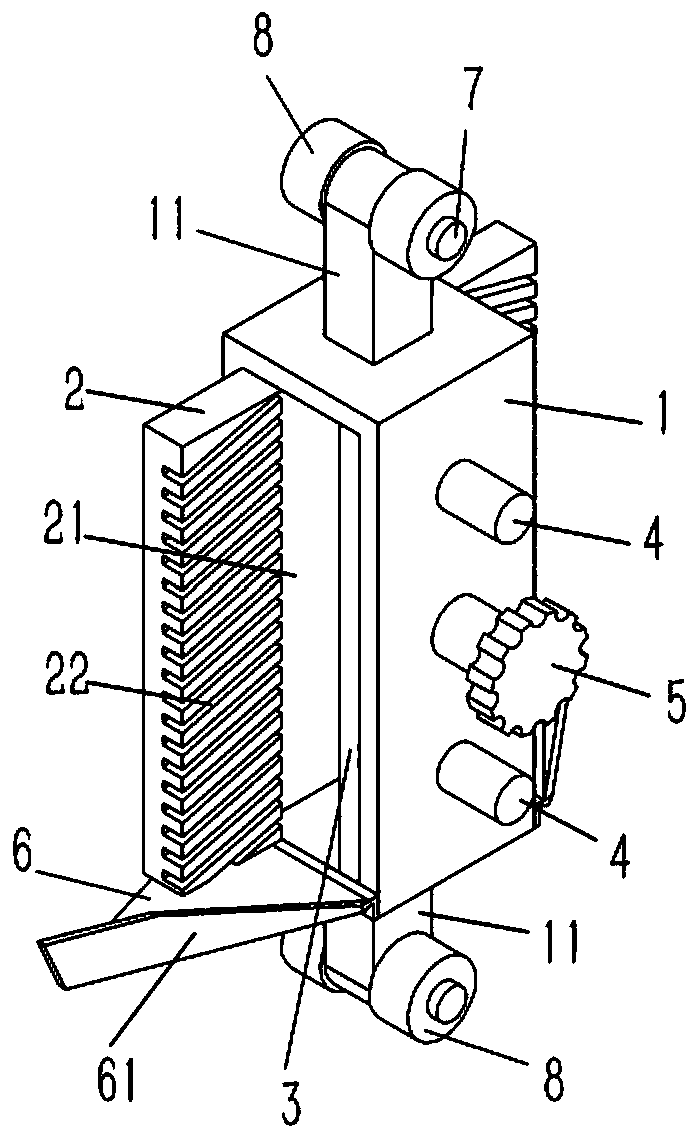

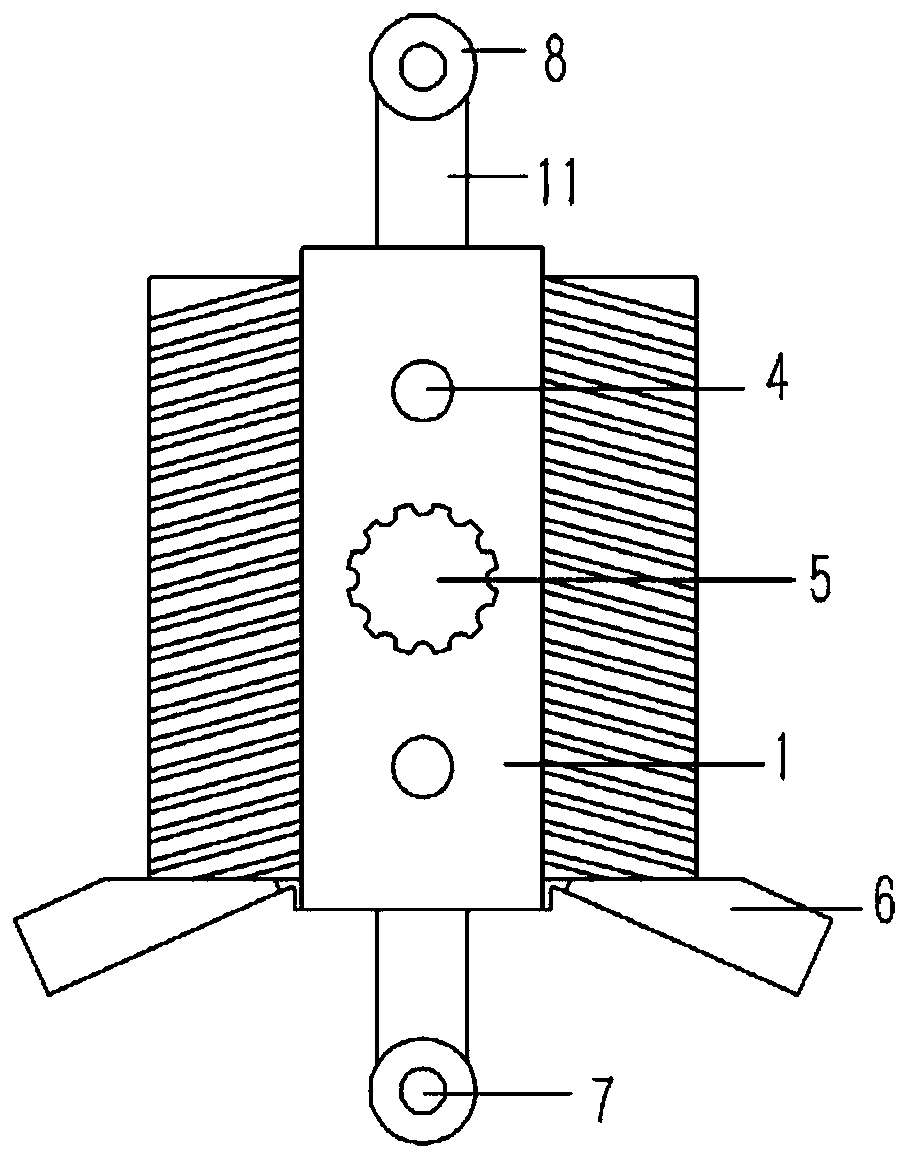

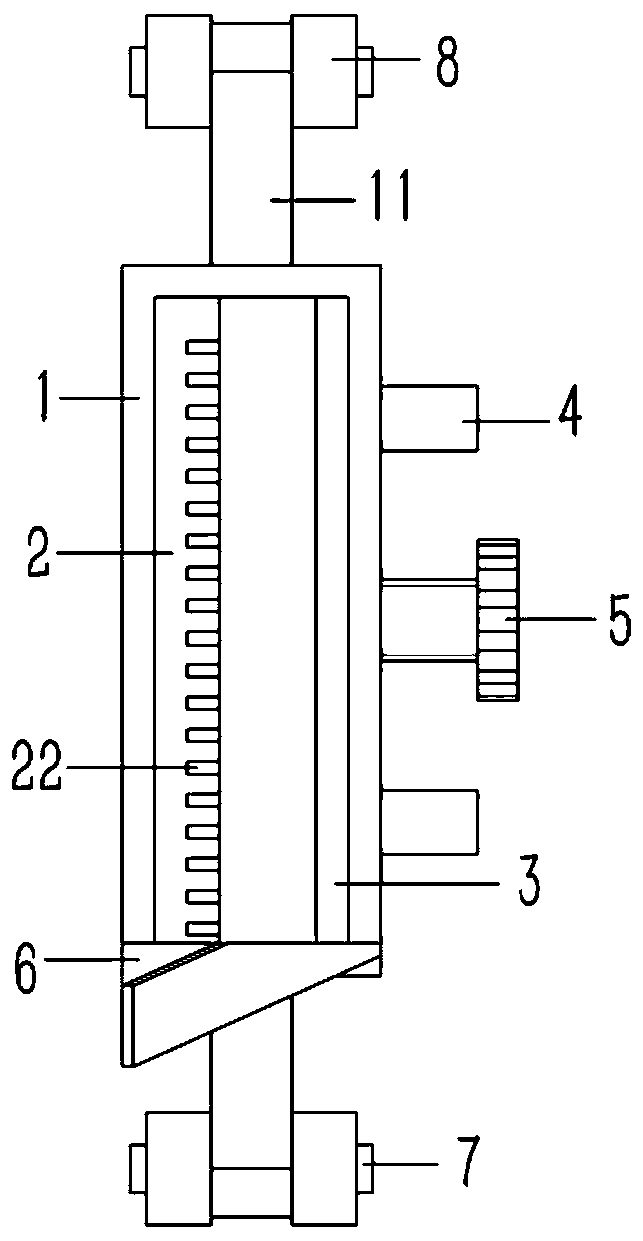

[0020] Example: see Figures 1 to 3 As shown, a jig for high-pressure flushing of packaged chips includes an upright and rectangular positioning frame 1, openings are formed on the left and right sides of the positioning frame 1, and supports are formed on the upper and lower end surfaces of the positioning frame 1. Ears 11, a vertical pin shaft 7 is plugged into the lug 11, the two ends of the pin shaft 7 are inserted and fixed with rollers 8; A rectangular positioning groove 21 is formed, and the two sides of the rear splint 2 protrude from the positioning frame 1 to form a number of oblique discharge grooves 22, and the front splint 3 is inserted into the positioning frame 1 on the front side of the rear splint 2; The front end surface of the positioning frame 1 is plugged with several longitudinal guide posts 4, the rear ends of the guide posts 4 are fixed on the front splint 3, and the front end surface of the positioning frame 1 between the guide posts 4 is screwed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com