Circular feeding barrel

A feeding barrel and circular technology, applied in the field of circular feeding barrels, can solve the problems of labor-intensive and reduced coffee bean production efficiency, and achieve the effects of convenient production, slowing down the falling speed, and improving efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

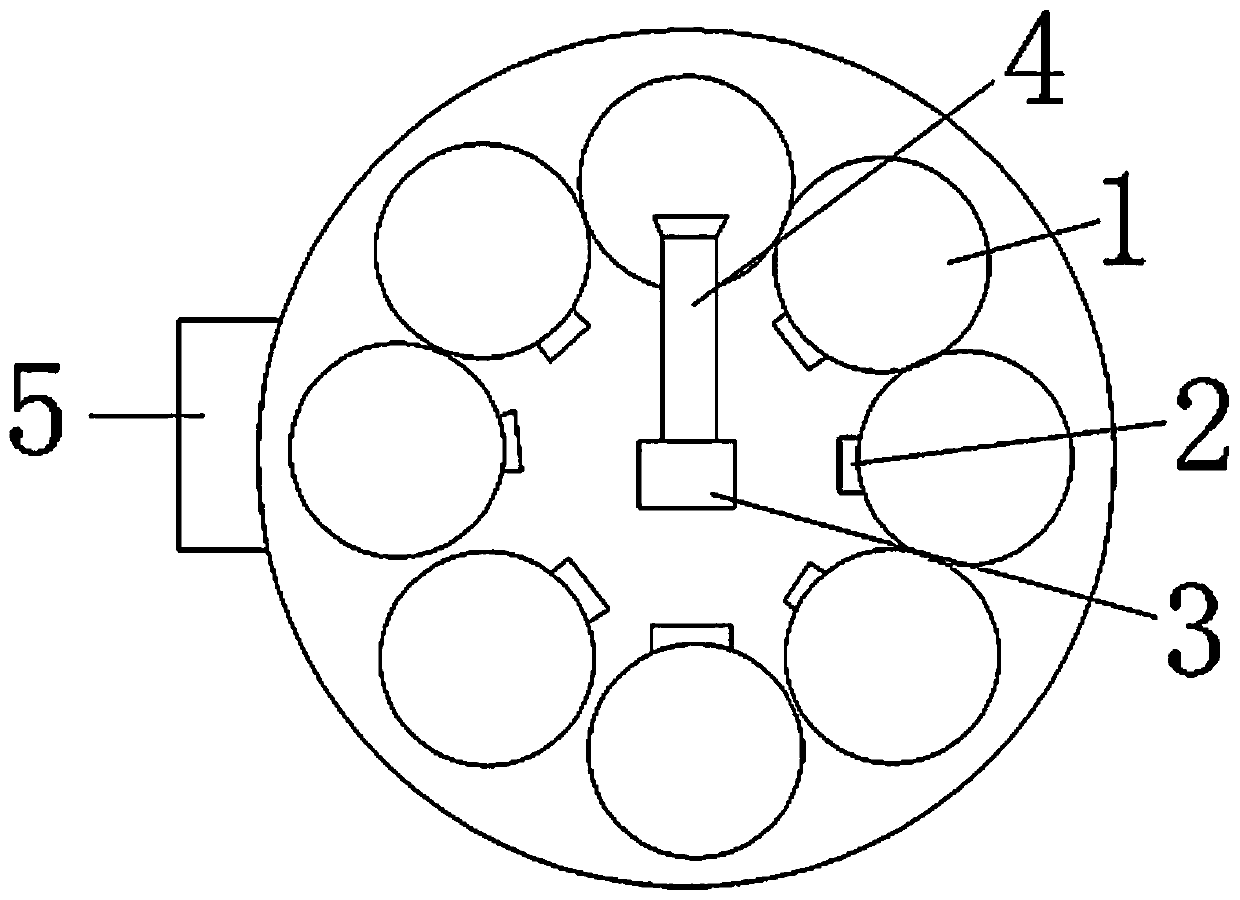

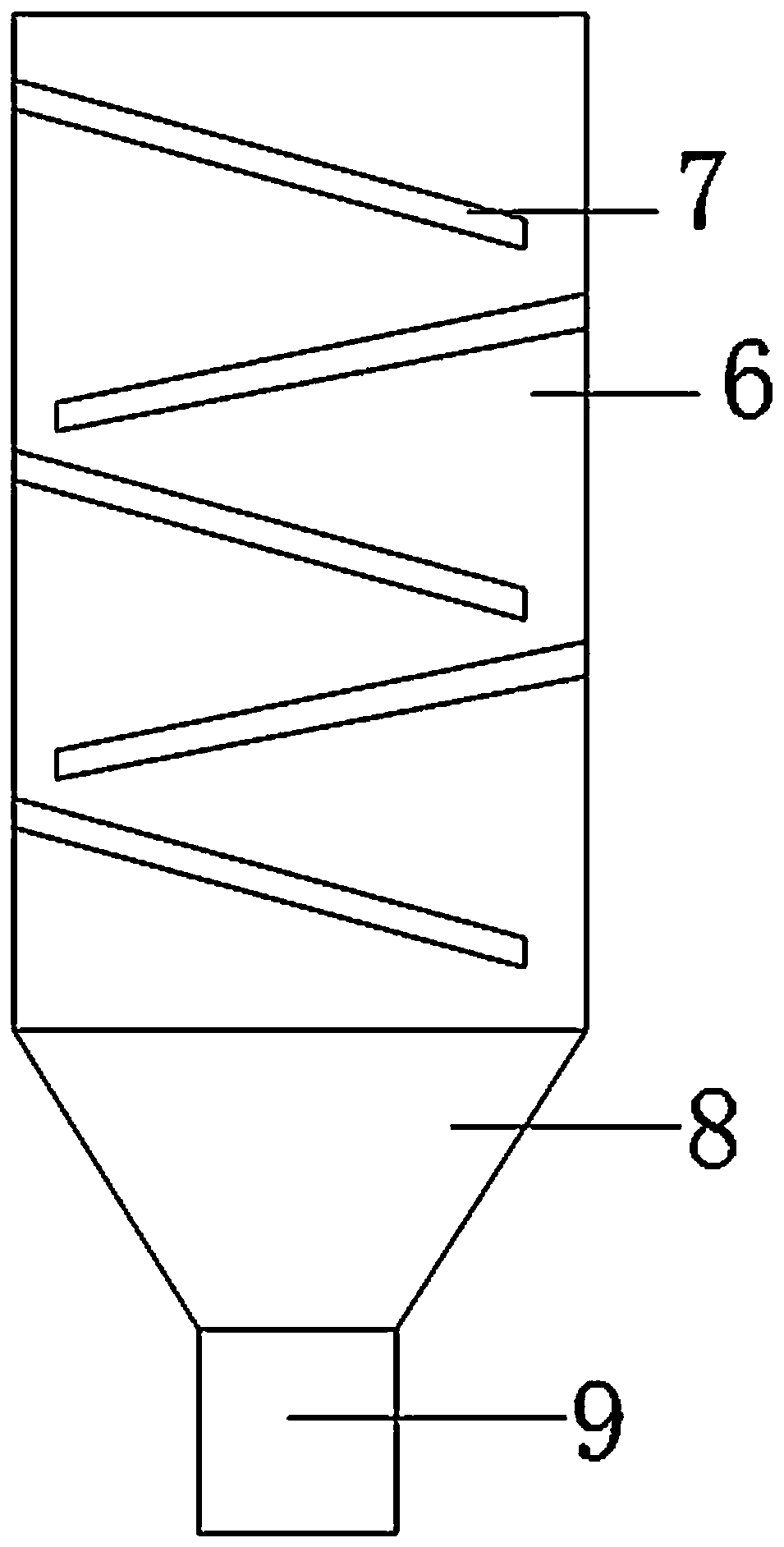

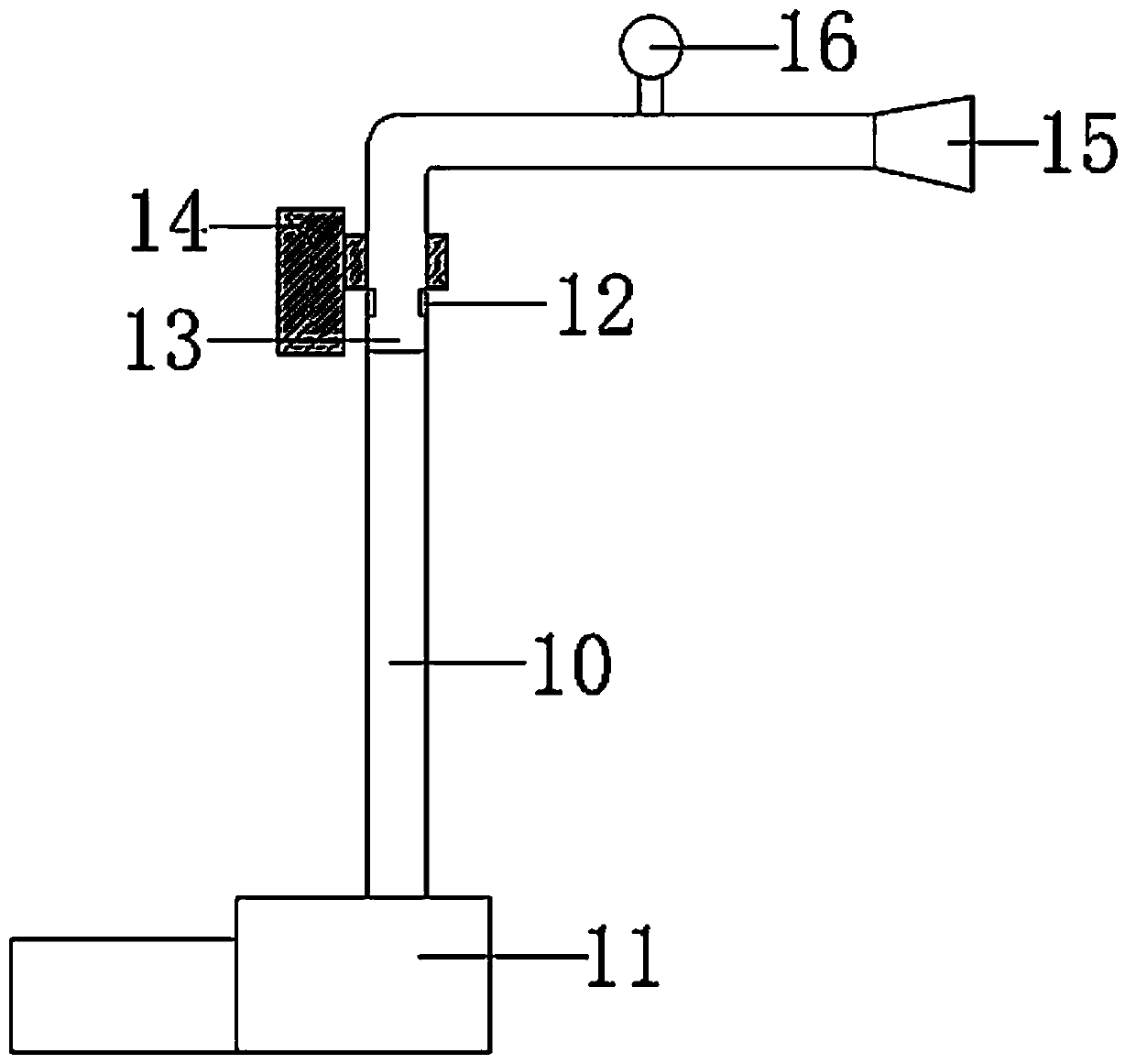

[0019] Figure 1-3 Show the specific embodiment of the present invention: a kind of circular feeding barrel, comprise feed through trough 1, laser emitter 2, laser detector 3, rotary feeding device 4 and wireless signal controller 5, eight feed through trough 1 and Arranged in a ring to form a cylindrical structure, the rotary feeding device 4 is set at the center of the feeding channel 1, the eight laser emitters 2 are respectively arranged on the corresponding feeding channel 1, and the laser detector 3 is arranged on the rotary feeding device 4, the laser emitter 2 and the laser detector 3 match each other, the wireless signal controller 5 is set on the feeding channel 1, and is connected with the rotary feeding device 4, the laser emitter 2, and the laser detector 3. The equipment facilitates the production and can automatically send cof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com